Thermal solutions are a part of almost every industry, from the production of chips and medical devices to oil and gas activities. What unites these different sectors is the need to design simple but reactive systems, able to monitor and maintain a precise application of heat. However, this need implies that engineers have to deal with various complexities. Here Brandy Phillips, head of engineering design at electrical resistor manufacturer Watlow, explains how adaptive thermal solutions (ATS) can provide an answer to the most common heat treatment challenges.

Any device or process equipped with a heating element needs some degree of thermal control, with some devices or processes requiring more precise control than others. Such accuracy is traditionally achieved by adding sensors and controllers to heating elements. The higher the accuracy required, the greater the complexity of the control apparatus and wiring.

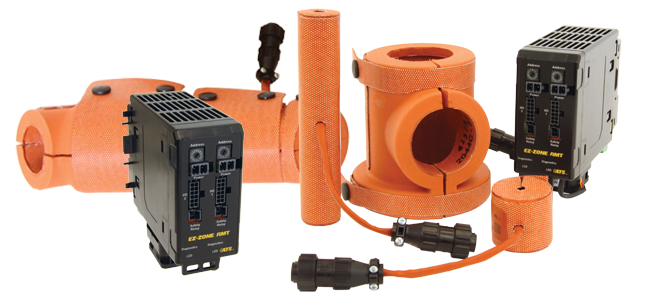

ATS, which combine sensing, heating and control technologies, represent a different and more innovative approach to controlling the thermal performance of complex systems. However, adding complexity isn’t always an option, and that’s where the challenges come in.

Complex systems in small spaces

A surface that needs to be heated within a certain temperature range requires not only several heating elements, but also sensors that can detect the temperature of the surface at various points. These sensors then provide feedback to a controller that responds by adjusting the power sent to the heating elements. In the event of fluctuations in surface temperature, the sensors and controller must be able to react in unison to maintain the desired temperature range.

Traditionally, the approach to achieving such precise control of the heating surface has been to increase the number of zones, which requires the addition of independent sensors, cables and controllers. As the system grows, the complexity increases, but not the overall space in which it is to take place. In many production scenarios, precise control is required in a confined space, and wiring and equipment cannot be added.

The challenges related to control systems

Manufacturers may experience a disconnect between their control systems. Different sensor banks at different points in a process are often connected to separate controllers, which may not be networked so that they can easily coordinate their activity, resulting in unresponsive systems.

This challenge often involves adding an element of unpredictability to the system. The additional complexity of additional sensors and controllers compromises adaptability in some applications or prevents the system from achieving the desired thermal uniformity. This in turn leads to an excess of waste and a variable quality of the material.

Solving these challenges

The accuracy and tuning of a thermal system is traditionally achieved by adding sensors and controllers to the system. But there are many applications where this option is not viable, including semiconductor manufacturing, analytical devices, and medical devices for home use. ATS enables a greater degree of control in systems where no other components can be added.

Each application is unique and some can take advantage of many ATS technologies at once, while others can only use one. In semiconductor manufacturing, the heating elements of deposition pedestals must reach certain temperatures during the chip manufacturing process, and temperature uniformity is critical for quality control. The pedestal itself leaves little room for additional wires. With high TCR materials and multi-ring control and sensing, individual heating elements can be transformed into sensors and the number of heating zones can be more than doubled. Such zones can be controlled independently, in real time, adjusting the power of the heating element to achieve a more uniform surface temperature.

In addition, existing medical and analytical equipment often has to meet new requirements from regulatory agencies, such as safety specifications for permissible temperatures. The presence of heating elements that can detect their own temperature and adjust power levels through power conversion helps to maintain temperatures

within safe limits.

Watlow, which manufactures industrial heating technology, has decades of experience in thermal systems to help engineers and designers incorporate ATS technology into a wide variety of industrial processes and products.

The beauty of ATS is that it is not a single solution, but a suite of solutions that can be adapted to specific engineering challenges. To reap the benefits of this technology requires a deep understanding of the product or process in question, including the thermal and power requirements of the system.

For more information about ATS, visitrand the watlow.com website .