PLASSON, a NIS1.3 billion (£285 million) turnover multi-national manufacturing business headquartered in Israel, relies on VERICUT CNC machine simulation, verification and optimisation software from CGTech to ensure high-quality, reliable and highly productive mould tool machining operations. Enhancing the manufacture of the company’s injection mould tools and associated parts, VERICUT is today embedded into machining procedures at this progressive OEM after more than two decades of continuous use.

As a global leader in the design and production of flow solutions (fittings and valves), livestock equipment systems, and products for bathrooms and kitchens, PLASSON maintains a tradition of over 50 years of excellence and innovation. Formed in 1963, quality is the key concept in all of PLASSON’S processes, from development and design through production, assembly, packaging, distribution, delivery and aftersales services. The company has a strong global presence, operating in more than 100 international markets, with approximately 2,000 employees and over 25 subsidiaries worldwide, including one in the UK at Burgess Hill.

PLASSON constantly aims to develop added value and stand at the forefront of technology in the development of innovative products and solutions that suit the ever-evolving needs of its customers. Such a philosophy relies heavily on the company’s in-house mould tool machining capabilities, which is where the capabilities of VERICUT come to the fore.

“We’ve been using VERICUT for over 20 years,” states Itamar Minerbo, Mould Department Manager at PLASSON. “It was originally introduced because we didn’t feel that we could fully trust the post processor. We were finding some differences between the CAM software simulation and the G-code files, where the software simulation didn’t show any problems. In contrast, running a VERICUT simulation shows very clearly whenever the tool follows a different path according to the G-code. For sure we’ve protected many mould tools against damage since installing VERICUT.”

The importance of protecting both components and expensive machine tool assets at PLASSON should not be underestimated. Although the company only ran two four-axis CNC milling machines when it first introduced VERICUT more than 20 years ago, today PLASSON has two Hermle five-axis CNC machining centres on site and a brand new multi-axis Nakamura turn-mill machine.

“Since we produce injection mould parts, there’s almost no serial production,” explains Mr Minerbo. “Each component is unique, which means we run VERICUT on every job that we program.”

PLASSON machines injection moulds, slides and electrodes measuring up to 300 x 300 x 300 mm in size. Materials include high-specification tool steels specifically for plastic injection moulds, as well as copper for the electrodes. These metals are typically expensive, even more so in the current inflationary environment for raw materials.

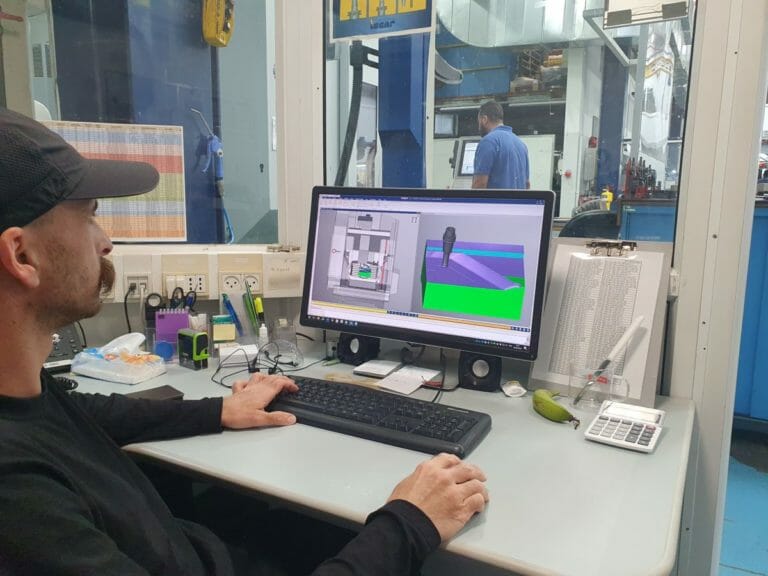

To help protect its workpieces and prevent costly rework or scrap, the company relies on VERICUT for all of its machining simulation, verification and optimisation tasks. Supplied by Z-CODE, a VERICUT reseller in Israel, PLASSON leverages the benefits of VERICUT base modules that include Verification (detects program mistakes and verifies part accuracy), CNC Machine Simulation (detects collisions and near misses between all components in the machining zone) and Multi-Axis (simulates multi-axis milling, turning and mill-turn operations).

“For every simultaneous four- or five-axis milling move we use the Multi-Axis module,” says Mr Minerbo. “Due to the type of jobs we’re processing, we rely on this module quite often.”

Adds Mr Minerbo: “The overall benefit of using VERICUT is the option to send the program to the machine with the certainty that it will run smoothly without collision. Of course, to ensure reliable results we always make sure that the tools, fixtures and workpieces are the same in the machine as in the simulation. That’s why we’ve standardised all the tools on both of our five-axis machining centres. For example, a 4 mm diameter ball-nose cutter will have the same length and same tool holder on both machines.”

PLASSON also takes advantage of the AUTO-DIFF™ module, which compares a CAD design model with a VERICUT simulation to detect differences, weaknesses or mistakes in the design and reduce the time needed to cut the first production-worthy part. AUTO-DIFF™ also reduces the time it takes to prepare an NC tool path. Programmers can check for gouges or excess material while working on the program, with problems identified and corrected before machining.

“We use AUTO-DIFF™ on all of our jobs,” reveals Mr Minerbo. “This module helps us to make sure we’ve covered every feature on the part by running the excess analysis function. If we’ve failed to program a specific feature, it shows up and we can fix it right away. AUTO-DIFF™ also helps to determine where the tool has removed more material than needed and, of course, any collision between the tool, tool holder, workpiece and fixture.”

To make the deployment of VERICUT even easier, further modules at PLASSON include the PTC-Creo Parametric interface and Esprit to VERICUT interface.

“We find that VERICUT is easy to use on a day-to-day basis,” concludes Mr Minerbo. “The software is very user-friendly and even those new to VERICUT get up to speed in a relatively short space of time.”