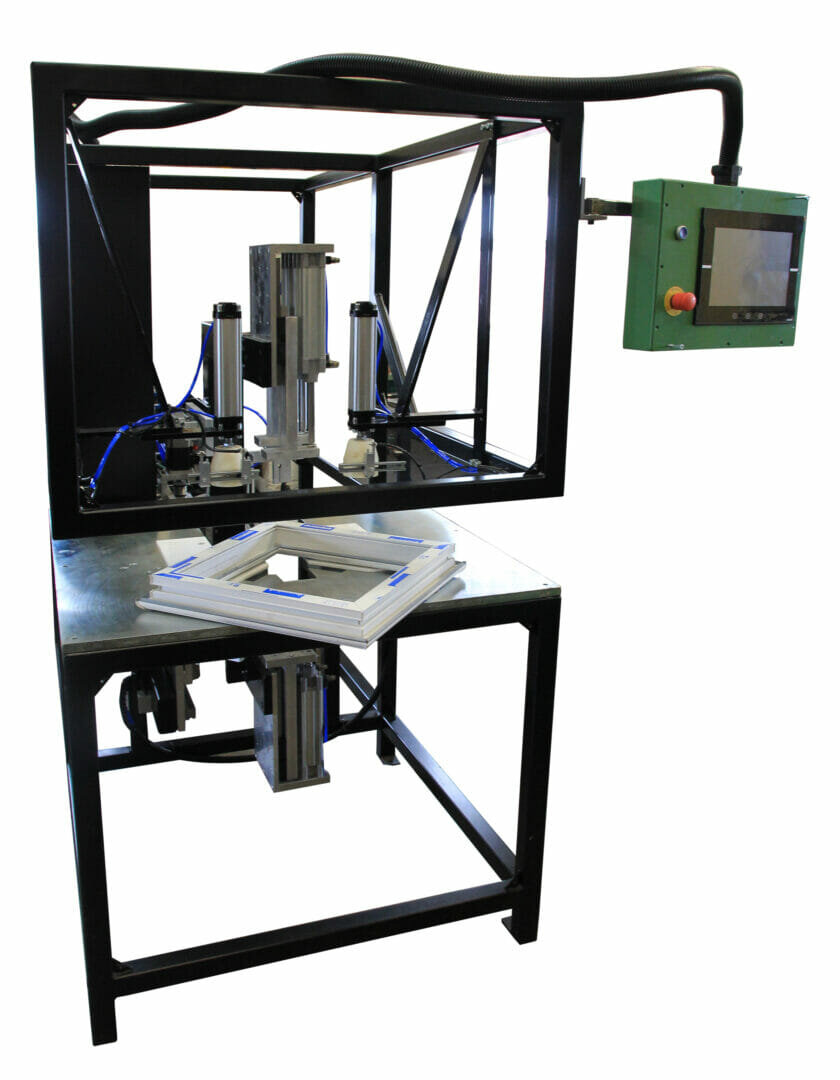

Matara UK Ltd, specialist in automation, pneumatics and linear motion products, has supplied linear rails and guides, and SFNHR precision ballscrews, to Pernamatic Engineering for a new CNC Corner Transom Machine for uPVC Double Glazed Windows. The XY linear system at the heart of the machine allows for tight tolerances and can be programmed to accommodate 100 different positions.

Established in 1996, Pernamatic Engineering provides professional, reliable precision engineering services, with a focus on the uPVC window industry. It designs and manufactures specialist uPVC window machinery, including Corner Cleaners which automate the process of removing the surface weld sprue which forms from welding the mitre joints. Whilst Pernamatic Engineering have an off the shelf Corner Cleaner, a customer needed a bespoke solution, which required a new XY linear system.

Pernamatic Engineering designed a CNC Corner Transom Machine for UPVC Double Glazed Windows to meet the customer’s exact requirements. At the heart of the new machine is an XY linear system which uses Matara MSB compact 35mm type linear rails and guides and SFNHR precision 20mm ballscrews which position the internal radius tool to 100 different programmable positions. All Matara components were available from standard stock for a quick delivery.

The MSB Series is renowned for its compact nature whilst maintaining a quiet and smooth motion. It features a 45° contact angle to bear an equal load in radial, reversed radial and lateral directions, along with high rigidity, four-way equal load and self-alignment capability.

The ballscrews, which are machined in-house at Matara, suit the fixed ballscrew end supports which give the ballscrew excellent rigidity. Additional benefits of using Matara linear ballscrews include high efficiency due to reduced friction during use, high load capacity at fast speeds, and cost-efficiency.

The resulting CNC Corner Transom Machine for UPVC Double Glazed Windows is both flexible and fast. It is capable of handling 200 different UPVC window frame configurations and finishes a complete frame in just 80 seconds. Previously, it was taking Pernamatic Engineering’s customer 15 minutes for an operator to finish each corner – a very laborious manual process using several hand tools. It is also highly accurate as the Matara linear rails and guides allow the machine to position the tool to 0.016mm tolerances.

Matara is part of Rubix, Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. For more information, please go to www.matara.com/, or contact Matara at sales@matarauk.co.uk or on 01684 850000.