From 12 to 16 September 2022, the beverage and liquid food industry meets at the world leading drinktec trade fair in Munich. NORD DRIVESYSTEMS will be presenting its solutions for the industry, which focus on energy efficiency and hygiene.

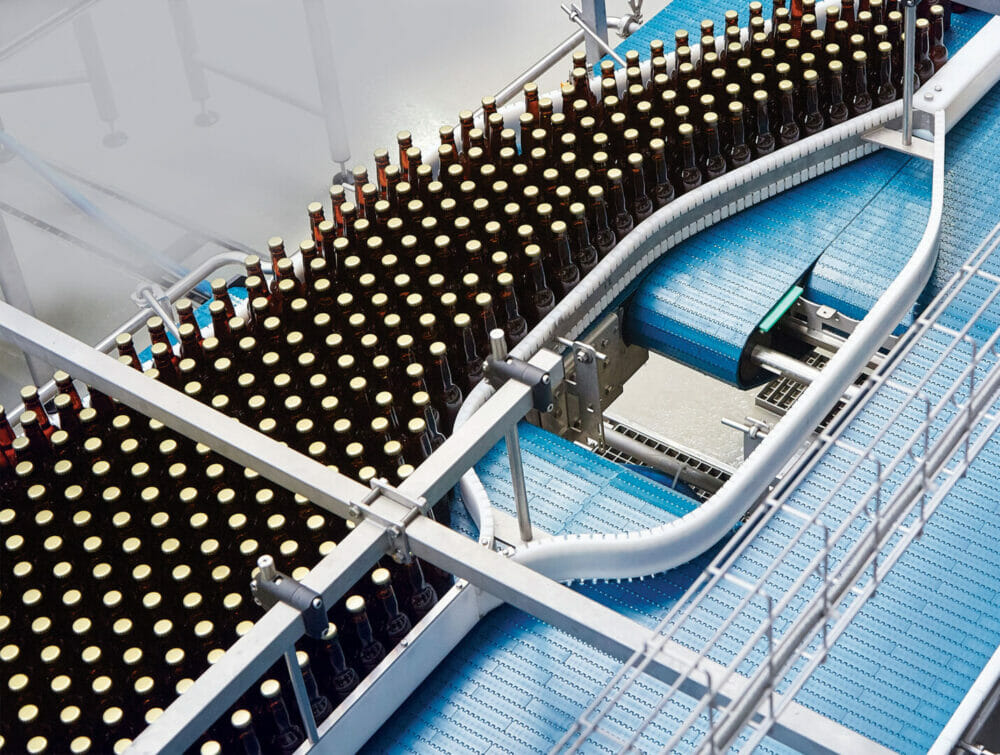

From cleaning to filling, sealing and labelling: Conveyor belts for bottles are often used in the beverage industry. To operate them in a particularly energy efficient manner, NORD DRIVESYSTEMS has developed a special drive solution: In the patented DuoDrive geared motor concept, an unventilated IE5+ synchronous motor was integrated into a single-stage helical gear unit. The IE5+ motor operates highly efficiently in itself and even exceeds the highest defined efficiency class (IE5). The integration into the gear unit results in additional optimisations by eliminating interfaces, some wear-prone parts and also installation space.

Up to 50 % energy savings

In a trade fair model, which NORD will also be presenting at drinktec, the drive specialist pits the DuoDrive against a customary IE3 asynchronous motor with bevel gear unit. “The geared motor was able to achieve an increase in efficiency of up to 50 %”, reports Jörg Niermann, Head of Marketing.

The geared motor realises another advantage for the beverage industry, since many systems do not usually run permanently under full load. “The DuoDrive can also be operated efficiently with partial load or individual overload peaks. It provides a constant motor torque over a wide speed range and operates efficiently over the long term”, explains Niermann. Thus, the DuoDrive can replace several differently dimensioned drive versions. Across the entire system, this will reduce the variety of the drive versions used. This enables leaner production, logistics, storage and service processes and thus minimises the administrative costs.

Corrosion-resistant and easy to clean

The DuoDrive and many other NORD drive components are corrosion-resistant and wash-down capable and therefore suitable for use in hygienically sensitive environments. Due to the smooth surface and the

integrated, unventilated motor, the DuoDrive is very easy to clean. It ensures low cleaning effort and thus low cleaning costs as well as high system availability.

On request, the wash-down-capable components can also be supplied with the nsd tupH surface treatment. This makes the aluminium surface particularly corrosion-resistant, similar to stainless steel. nsd tupH is not a coating but a surface treatment permanently bonded to the substrate material so nothing can detach or flake off.

For hygienically sensitive applications

nsd tupH-treated components are largely resistant to acids and alkalis and can even withstand the use of

high-pressure cleaners. nsd tupH treatment is available for most of the aluminium products in the NORD

modular drive system, and ideally suited for hygienically sensitive applications in the food sector.

NORD will be presenting its solutions for the industry at drinktec from 12 to 16 September 2022 in Munich.

You will find the company at Stand A3.233.