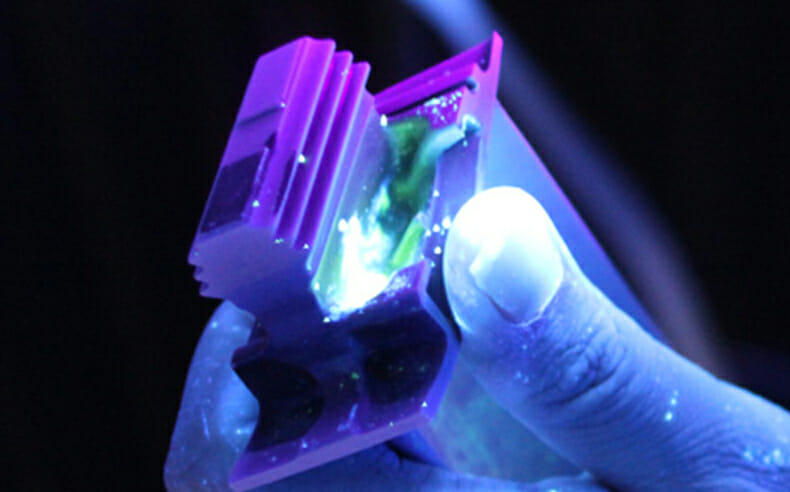

The perfect NDT solution for inspection of components, Liquid Penetrant Testing or Fluorescent Penetrant Inspection (FPI) is commonly used in the aerospace industry. Precision surface finishing leaders, Kemet, now offer FPI systems with advanced process control that ensures repeatability, process safety and traceability of each batch within the set parameters.

Designed and built by renowned ultrasonic cleaning machine manufacturers, FinnSonic Oy, the systems meet the ASTM E1417 FPI standard common to the aerospace industry. Kemet have a range of standard systems as well as the flexibility to combine automated and manual operation to providing streamlined, maintainable NDT inspection with integrated waste water handling and extraction systems as options to create cost savings on process chemicals, labour and energy consumption.

Finnsonic have supplied fully automated systems for airframe components, turbine blades, and medical implants as well as smaller manual systems for less critical parts. An intelligent combination of automation and manual handling provides labour savings while an adjustable layout can provide a small footprint. As with Finnsonic’s ultrasonic cleaning machines, these FPI systems are durable, safe, ergonomic and user-friendly.

A variety of systems are available, from flexible manual roll track spray lines, with a small footprint, to fully automated roll conveyor immersion lines for high capacity, mass production with dipping penetrant application, “Dust Storm” developer chamber and integrated pre and post wash. Further options include material handling and batch traceability via a data log, fully automated penetrant and developer spray, basket rotation, basket trolleys and automatic loading/unloading conveyors

For more details contact Kemet on Tel: +44 (0) 1622 755287, email: sales@kemet.co.uk Bottom of Forma