The new equipment supplied by Thar Processes will help De Dietrich to test in-house and scale-up extraction and purification technologies for its customers in pharmaceutical and plant-based industry.

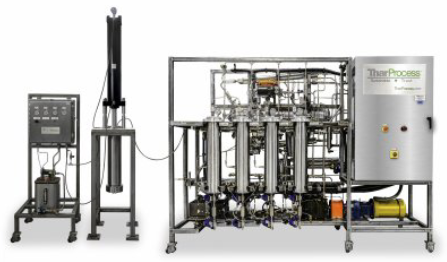

De Dietrich Process Systems is strongly developing its presence in solutions based on supercritical CO2 technologies. “We are convinced by supercritical CO2 as an environment-friendly alternative to conventional organic solvent. It is upcycled and recyclable. And it is not just green, it has a low TCO [Total Cost of Ownership], its installation is easy and doesn’t require ATEX environment.”, explains Frédéric GUICHARD, Business Unit Managing Director, Pharma & Green Solutions. To further develop its expertise and make this equipment available to its customers for tests, De Dietrich has acquired 2 different equipment, for extraction (SFE) and for purification (SFC).

Supercritical technologies are highly tunable and scalable. And they show a high potential for lots of customers. With the acquisition of pilot CO2 extraction and CO2 chromatography equipment, de Dietrich wants to demonstrate the full potential of supercritical technologies based on Thar Process’ experience. Thar Process is a pioneer in this field, with records with many “Fortune 500” customers. The American-based company also operates its equipment its Pittsburgh facility as a toll processor. With experts present in Europe, the partnership with De Dietrich was then obvious.

These 2 equipment will be installed by the end of the year in a dedicated unit of the Tech Lab, in Semur-en-Auxois, France. The Tech Lab is the testing and development center for new process solutions. It is built for the Pharma and Green Solutions Business Unit of the DD Group with the support of France Relance. “Supercritical CO2 will be available as new unit for tests, amongst the conventional drying and powder handling technologies”, concludes M. GUICHARD, “With easy access and training by Thar Process and De Dietrich experts, we will spread this green technology”.