For many data center managers, maintaining storage capacity for data is a continuously moving target. A fine line exists between investment in additional capacity and leveraging and upgrading existing installations. Data centers can cost anything from tens of millions of dollars upwards, with some of the industry’s behemoths reportedly having spent over a billion dollars on such infrastructure. And readiness to invest doesn’t turn into capacity quickly. Factoring in construction, electrical and plumbing work, plus installation of the hardware and commissioning, it can be anywhere between 15 and 30 months before a data center is operable.

Many choose to outsource their data operations, a market that is projected to see good annual growth over the remainder of this decade. But colocation data centers, despite their efficiency through shared resources, aren’t for everyone, especially for those handling sensitive data. Another challenge is the growing demand in the Internet of Things (IoT) and Industry 4.0 markets for providing sub-millisecond latency support at the edge, along with 5G, big data, and artificial intelligence applications.

Going Modular with Data Centers

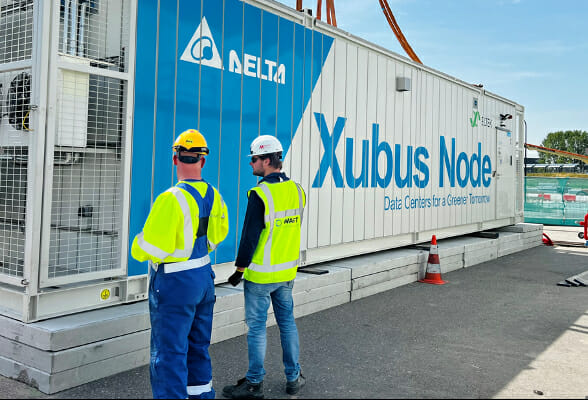

Tackling these issues head-on are modular data centers (MDC). Customizable in size and capacity, they can provide a stopgap solution on-site as a new data center is being built or can operate as a permanent solution in locations where setting up long-term infrastructure is restricted. Installation on-site enables the MDC to be connected securely to the existing IT system while leveraging existing physical security (Figure 1).

The Delta Xubus Node, a scalable, prefabricated MDC, is fulfilling these demands. Fully designed and optimized, deliverable in 5 standard solutions from 18 to 90 kW IT load with optional auxiliary systems. The system is built into a customized container module (5635 – 13380 × 3300 × 3200 mm) that is designed to be transported, installed, and operated on a client’s site. IT load per rack ranges from 6 kW to 8.18 kW and comes with a battery backup time of five minutes (Figure 2).

Depending on the topology (Tier 2 or 3), the uninterruptable power supply (UPS) is implemented using Delta’s DPH Series in an N+1 or 2N approach. Each rack is fitted with a metered power distribution unit (rPDU) or two for a Tier 3 implementation. At Tier 3, the MDC can be serviced anytime without shutting down any system components, thanks to the redundancy implemented. In addition, an integrated automatic transfer switch allows a simple installation and use of external diesel generators.

In-row cooling is implemented with N+1 redundancy and the Tier 3 topology uses cooling units with

automatic transfer switching (ATS). This allows operation of the MDC over the -15°C to +48°C range. The

cooling units have an internal monitoring system, which continuously control both temperature and humidity. It detects various types of critical events, e.g. congested filters, and triggers an alarm if the parameters reach critical values.

A selection of optional components is also available to increase safety, security, and reliability. An access control system and CCTV ensure only authorized staff can access the data center, while the situation inside the unit is always visible. Aspirating smoke detectors and fiber cable trays are further options, as well as additional hardware configuration. The Data Center Infrasuite Manager (DCIM) software can be used to monitor the MDC, providing an overview of environmental parameters (temperature, humidity), the access system, power, and status of the fire suppression equipment

Thanks to its robust steel construction and mineral wool panels, coupled with a refractory cable entry, fire resistance of 60 minutes (EI) in both directions is achieved.

Transportation, Installation and Support with Zwart

Delta has successfully deployed the Xubus Node MDC with the support from long-term partner Zwart

Techniek, who takes care of the system integration and handles ongoing support, based on its great

technical expertise and extensive service capabilities. With 150 employees and operations in Europe, Africa and the Middle East, their trained professionals are qualified to design, engineer, realize, and maintain highly-integrated data centers. Zwart Techniek partnered with Delta to support the transportation, installation, commissioning, and service of Europe’s first Xubus Node, which is also the first containerized data center built and sold in Europe. Meeting the customer’s financial requirements with a new leasing model, this 70 kVA model was delivered to a client based in the Netherlands (Figure 3). Selected to provide data center support while a permanent data center is under construction, the unit was configured and installed in less than nine months and will provide at least 24 months of service.

Interest in customizable containerized data centers continues to grow for various reasons, from bridging capacity until a permanent data center is completed to expanding capacity in locations where a permanent structure is impossible. MDCs such as the Xubus Node provide scalable installation options, offer enough customization to meet specific needs, and deliver up to Tier 3 topologies for secure, safe, and reliable IT infrastructure. Thanks to the MDC’s performance and the business model behind it, a significant uptake in this approach to expanding data centers across Europe is expected. Available in short time frames and supported by many local experts, Delta aims to support IT managers in the EMEA market to grow capacity and capability flexibly without limitations.

For more information about Delta’s prefabricated MDC, please refer to:

www.delta-emea.com/en-GB/solutions/Datacenter-Solutions/prefabricated-data-center; for more

information about Zwart Techniek, please refer to: www.zwarttechniek.com/