If you were to put a figure on enhanced productivity, what would your ultimate manufacturing output goal be? Five percent, maybe ten? Given the current challenges, some processors may even push for 20 percent! Research by Sumitomo (SHI) Demag reveals that when all the productivity production stars align – including optimising all-electric technology, engaging people, utilising automation and other digital tools, and reducing production downtime – 50 percent or higher is entirely reachable.

Productivity is the hot topic at Interplas 2023, with a number of seminars and panel discussions already scheduled. Inevitably, these programs will showcase and share best practice on how to ‘achieve more output with the same or less effort’. After-all, this is the ultimate quest.

Ahead of the productivity curve is Sumitomo (SHI) Demag. Gathering information and data when visiting customers following new all-electric and machinery installations, the team reveals everything they’ve learned. Including how both small and large polymer processors can lean on their technology and team to unlock more untapped productivity opportunities.

All of this information is being captured in an insightful new Whitepaper. However, given the significance of this trailblazing evidence and yield-boosting benefits, the team shares a taster of how mass moulders can, with just a bit of expert support and guidance, double their manufacturing capacity and productivity.

Turning empty promises into reality

Imagine the profit possibilities if each all-electric injection moulding machine within your fleet delivered an extra six months of processing capacity. How many extra projects could you take on? How much machine footprint could this save? What would this mean for your delivery schedules and customer satisfaction?

Phased Total Factor Productivity improvements to manufacturing processes holds huge promise. For many UK moulders, this could finally be the golden egg to change the operational landscape and future prosperity of polymer manufacturing firms of all sizes?

Integrating an all-electric machine into production lines, alongside intelligent utilisation of digital tools and automation, combined with investing in training and development, can decrease cycle times by up to 55% percent. This can equate to an extra 168 days of production, illustrates the Processing Productivity whitepaper.

It doesn’t require doing everything all at once. Instead, the Sumitomo (SHI) Demag team assures customers that in a short space of time, marginal gains can unlock accumulative enhancements to boost profit margins.

All-electric closes the productivity chasm

It’s widely considered a ‘given’ that energy efficiency and reduced pollution are the benefits of all-electric injection moulding machines. Especially in today’s eco-conscious manufacturing world. However, beneath the hood of these machines are a number of velocity and injection power features that, when used correctly and repeatably by moulding operatives, result in faster cycle times and more stable start-ups. Even before any process optimisation steps have been introduced and expert setting knowledge has been imparted.

The advanced direct drive technology deployed by the IntElect series illustrates this point. Reducing a 10 second dry cycle time by just 0.55 seconds, for instance, can equate to an additional 2,274 cycles every day. Multiplied, this productivity improvement alone can add up to 14.3 extra production days!

MGS Technical Plastics is just one customer that observed an instant dry cycle time improvement of six seconds after switching from a Demag Ergotech 50ton to an IntElect2 50ton. “From these figures we can deduce that it equates to a 20 percent increase in cycles per year, giving MGS over 53 days of extra production capacity,” notes area sales manager Ashlee Gough.

People power

As efficient as these state-of-the-art machines are, they are only as good as the people operating them. For teams and individuals to put their best efforts into their work, they need to feel engaged, confident and valued. When they do, quality rises and productivity soars. These are the people you want to keep. They work harder, complete tasks to the best of their ability, deliver better customer service, question processes and are innovative problem solvers.

In-person field support and professional development courses plays a huge role in delivering the right diffusion of skills to maintain this proactive level of productivity engagement. “When teams feel like you are invested in their development and future, they champion further process improvements. This, in turn, has a lasting and invigorating effect,” reports MGS Technical Director Judson Smythe.

Nothing illustrates this point better than the eyewatering results gained when MGS participated in post-installation training. By optimising the machine set up, the Lancashire firm improved their ‘before training’ dry cycle times on the IntElect by a further 10.1 seconds. Compared to the original 29 second cycle time process, the optimised IntElect after training ran at 12.9 seconds. Resulting in over 761,000 more cycles per year, equating to 168 days of extra production “This on-site training helps even the most astute and skilled operatives to explore the full potential of features like parallel functions and how this supports the mould opening and closing speeds,” affirms Ashlee.

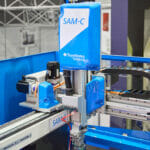

Adding robotics into the mix generates at least another five percent in higher productivity. More, if manufacturers can introduce ghost shifts. To demonstrate the potential untapped after-hours production opportunities, this year’s Interplas showcase premiers a compact, fully-automated, compact IntElect75 ton turnkey cell. “Rather than operate split shifts or keep people in the factory until late at night, this cell illustrates to trade moulders and SMEs how they can confidently harness the benefits of automation when manufacturing standard components. To save costs, moulding firms may introduce ‘ghost’ night shifts to ramp up their manufacturing capacity even more. Equally, day-shift teams benefit from augmented workflow processes,” points out Managing Director Nigel Flowers.

For productivity to be sustained, marginal gains is the best approach. Every incremental improvement boosts productivity that little bit more. Providing polymer manufacturers with greater capacity to take on new customers and more projects. “Even in the most profitable organisations, there’s great potential for improving efficiency and workforce competence. The key is to start with the basics; correct operation and setup times; review manual and automated routines; optimise machine cycle times, etc.,” states Nigel.

Find out more and pick up your copy of the Sumitomo (SHI) Demag Processing Productivity Whitepaper at Interplas, Hall 4, Stand C40 or download it today here: https://uk.sumitomo-shi-demag.eu/make-more-for-less