Atomic absorption spectroscopy (AAS) serves a variety of academic studies, but identifying its precise usages in industry can be difficult to determine. Selecting the best technique from those available leads to a further dilemma; of the options available, which is best suited for the objectives you wish to accomplish? Here, Paul Vanden Branden, director and product manager at laboratory equipment supplier SciMed, discusses the applications of AAS technology in sectors ranging from petrochemical and nuclear energy, to food and drink production, to sustainability and agricultural practices.

AAS provides a technique unmatched in precision, sensitivity and simplicity in operation. While other techniques often require advanced training and increased cost to operate, AAS offers the advantage of having simple, reproducible procedures and established reliability.

AAS measures the concentration of elements in various materials. By using known electromagnetic wavelengths, the technique can detect the intensity of the wavelength and this can be converted into accurate concentrations using the Beer-Lambert Law

It is this simplicity that has facilitated the accelerated advancement of AAS development. AAS not only provides a high degree of accuracy, varying by only 0.5 – 5%, but it can detect elemental concentrations at incredibly low levels; as low as just a single part per million in a single gram of substance. But AAS can also measure up to percentage concentration levels as well; this flexibility and wide working dynamic range means AAS is extremely useful for a large number of applications.

Atomic absorption spectroscopy applications

AAS provides an effective way to check for safety in a variety of sectors. For example, it is the Environmental Agency’s go-to procedure for checking the Environmental Quality Standards of water in the UK. Where drinking water may contain high levels of minerals such as lead, AAS can ascertain its concentration, allowing for safe and conscientious decision-making.

In a time where sustainable food production is a priority for many, AAS allows professionals to analyse soils for mineral content. Giving people the knowledge to understand which crops are best suited for an environment, reducing waste and smashing food production targets along the way.

AAS also supports and can analyse samples in a number of different industries, including the mining, petrochemical and nuclear energy sectors. By using AAS in these sectors, experts in these sectors can determine the amounts of contaminants in oil, gas or nuclear power resources. This would allow them to make sure that any future usage of non-renewable resources is as efficient as possible, allowing us to extract as much energy as possible from each of these resources.

This also has the added benefit of allowing engineers to monitor the composition of fuels, lubricants and coolants used in these processes. This provides a predictive method of preventing equipment failure and ensuring efficient operations, potentially saving thousands in maintenance and repair fees.

AAS comes in multiple types, each of which is specifically designed for its role.

Flame AAS (FAAS) can quickly and effectively test and measure for specific elements in substantial concentrations. More advanced graphite furnace or hydride generation variants can be used in situations where either the sample size is limited, allowing material scientists to confidently analyse the smallest of samples, or where the detection levels need to be at much lower concentrations. By using these methods, they can provide answers and predictions without using large amounts of product to generate these results, allowing for a more efficient workflow in industry.

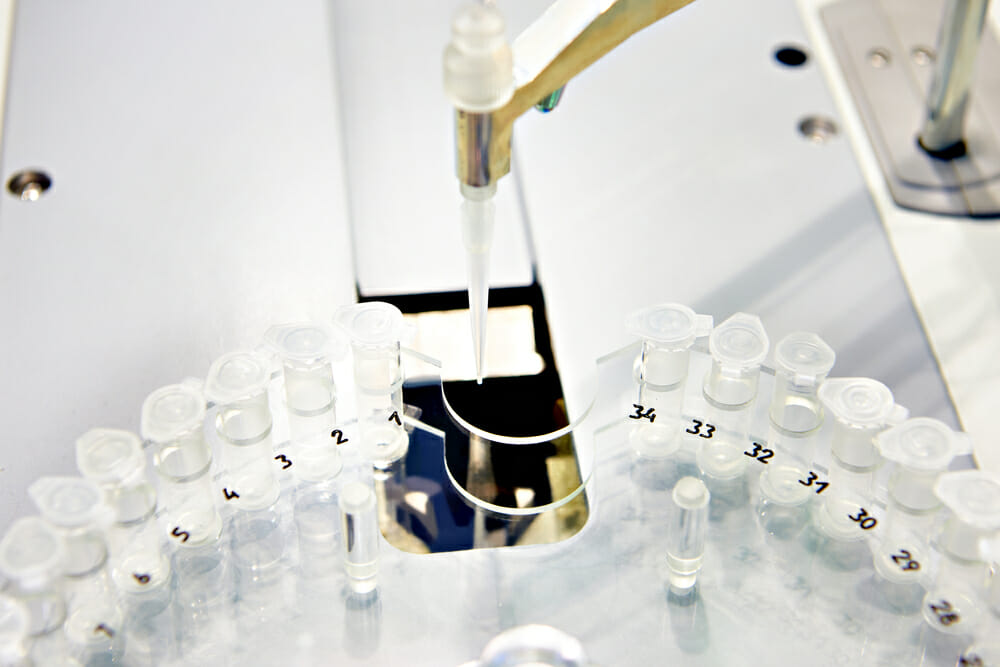

Otherwise, for the situations where time is of the essence and assured analysis is needed, SciMed supplies the unique Analytik Jena Continuum-Source High Resolution ContrAA system. This advanced technology allows its users to analyse multiple elements simultaneously from a single electromagnetic source. This results in a much greater sample throughput than can be achieved using standard source AAS instruments.

This technique presents substantial potential, allowing for quick quantification of unfamiliar materials. Its precision is advantageous in pharmaceutical quality control, verifying elemental content of medication, and optimising material analysis in metallurgy, electronics, and forensic science, where quick and accurate results are crucial.

For further insights into SciMed’s range of innovative AAS instruments, visit: https://www.scimed.co.uk/product-category/atomic-absorption-spectroscopy-aas/