Subcon 2024, scheduled for June 5-6 at the NEC, Birmingham is the premier event for manufacturing buyers across all sectors. As a cornerstone event for the industry, Subcon provides an unrivaled opportunity to source your next manufacturing solutions from a variety of world-class exhibitors. With over 150 subcontractors and outsourced engineering services, Subcon is packed with possibilities for everyone.

This year’s event promises a refreshed and innovative format, with new developments introduced to adapt and enhance the experience for both visitors and exhibitors. Attendees can look forward to a dynamic programme featuring interactive CPD-accredited workshops, cutting-edge product demonstrations, and insightful keynote presentations. Additionally, you can engage in meaningful discussions through roundtable sessions that are designed to foster collaboration and idea-sharing.

Whether you are aiming to benchmark your capabilities, seeking innovative solutions, or simply looking to stay ahead of industry trends, Subcon is your gateway to the future of manufacturing.

World-Class Manufacturing Solutions from Industry Leading Exhibitors

Meet with over 150 leading UK and international suppliers under one roof, showcasing the latest innovations and solutions available from sectors such as CNC machining, metal fabrication, electronics, component parts, and more, all dedicated to advancing the capabilities of your supply chain.

Thousands of new products and innovations will be on display across the full range of advanced engineering technology, systems and services – from Additive Manufacturing and Metrology solutions to Frictionless bearings, cables and controls, and everything in between. This is a show geared to helping you increase capacity, optimise productivity, improve flexibility and remain competitive.

Revamped Workshop and Sessions Programme: A Hub of Innovation and Learning

New for 2024, Subcon has announced a significant enhancement to its conference and workshop programme, with the introduction of a variety of different session formats that take place within three specialised areas; designed to cater to a diverse range of interests and professional needs within the manufacturing industry: the Innovation Zone, Workshops and Learning Space, and the Manufacturing Insights Theatre.

Additionally, the programme is now officially CPD accredited, ensuring attendees can gain valuable professional development credits while engaging with top industry experts and cutting-edge technologies.

Manufacturing Insights Theatre:

Explore insightful keynote presentations and engage in lively panel discussions at the Manufacturing Insights Theatre. This forum features thought leaders discussing the latest trends and challenges in manufacturing. Each session includes interactive Q&A segments, making it a dynamic platform for learning and engagement.

Workshops & Learning Space:

Dive into hands-on learning with roundtable discussions and sector-focused peer-to-peer meetings in the Workshops & Learning Space. Tailored to address specific industry challenges, these sessions offer practical insights and networking opportunities, facilitated by industry experts.

Innovation Zone:

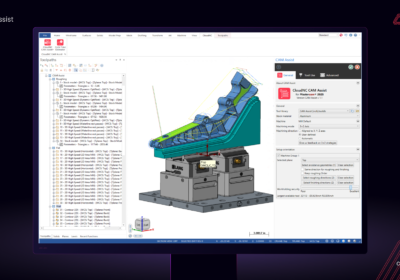

This area is dedicated to hands-on demonstrations, showing you how new technologies and products operate in real-time. It’s the perfect place to see the newest innovations in action and discover how they can enhance your manufacturing processes.

That’s not all! More NEW features include:

Motorsport Simulators & Prize Draw: Compete in professional motorsport simulators operated by FP Zero. Dive into the thrilling world of Formula 1 racing right on the exhibition floor. The fastest lap will not only boast bragging rights but will also win a PalmerSport driving day experience valued at over £600!

Dedicated Work and Meeting Spaces: Need a quiet spot for a meeting or just to catch up on emails? Subcon now has dedicated spaces set up for exactly that. Stop by to meet with peers or to take a break and grab a coffee.

Networking Drinks & Entertainment: All visitors, exhibitors, and speakers are invited to unwind at a welcome drinks reception, complete with entertainment, starting at 5 pm on the first day of the exhibition.

The Subcon Manufacturing Solutions Show Awards

Another feature new for 2024, the Subcon Manufacturing Solutions Show Awards, set to take place within the exhibition on Thursday the 6th of June. The Awards are designed to celebrate the best and brightest in the industry, are free to attend and are open to all visitors!

Award categories include:

- Start-up of the Year

- UK Manufacturing Partner of the Year

- International Manufacturing Partner of the Year

- Product Innovation of the Year

- The Rising Star Award

- Lifetime Achievement Award

7 Sessions You Don’t Want to Miss!

How can digital manufacturing, AI, big data and Industry 4.0 technologies support improvement in the workplace as well as wider society?

Thursday 6th June @ 11:00am | Manufacturing Insights Theatre – Panel discussion

- Dr Nandini Chakravorti, Associate Director, Digital Engineering Group, Manufacturing Technology Centre

- Prof Jeremy Watson, Professor of Engineering Systems, Net Zero What Works Centre at UCL

- Prof Mercedes Maroto-Valer, Champion and Director – UK Industrial Decarbonisation Research and Innovation Centre (IDRIC)

What are the keys to building enduring supplier-buyer partnerships

Wednesday 5th June @ 13:15pm | Manufacturing Insights Theatre – Presentation and Q&A discussion

“In today’s dynamic business landscape, forging strong and lasting partnerships between manufacturing suppliers and buyers is crucial. The panel will explore the critical factors that ensure top-quality, long-term collaborations.”

- Andy Sandford, Editor, Engineering Capacity

- Anil Thomas, formerly General Manager – Business Transformation And Projects, Olympus

- Lyndsey Adams, Manager: Purchasing & Supply Chain Operations, Dennis Eagle UK

Top tips for improving your bottom line: A case study from BAE

Wednesday 5th June @ 12:00pm | Workshop and learning space – Round table discussion

“An insight into how business can improve its bottom line by focusing on improving flow. A systemic approach looking at how lean and TOC can work hand in hand to strive for the top line to become the bottom line in a company.”

- Alan Lothian, 3A Business Excellence

- Andy Watt, Goldratt

- Frances Shaw, Goldratt

- Senior Manager, BAE

Concept to commercialisation: Innovations and challenges with co-developing disruptive technologies

12 noon Wednesday 5th June @ 12:00pm | Manufacturing Insights Theatre – Presentations and QandA discussion

“We will share an understanding of the challenges involved in commercialising an innovative product idea and how to avoid them, as well as a roadmap to follow to take your own concept and commercialise it successfully.”

- Daniel Bonilla, Senior Procurement and Supply Chain Leader, First Hydrogen

- Nigel Clarke, CEO, Morgan IAT Ltd, CEO at Zeus Sleep Ltd, Member of the Board at GTMA, Panel Member at Wessex Innovation

Supply chain and internal collaboration in the automotive sector

11:50 Thursday 6th June @ 11:50am | Manufacturing Insights Theatre – Presentation and Q&A discussion

“How can genuine internal collaboration create ways of working together to deliver corporate requirements, build in ESG policies and work effectively with your supply chain.”

- Andy Skelton, Head of Supplier Quality, Forseven

How to get started with automation

Thursday 6th June @ 14:40pm | Manufacturing Insights Theatre – Panel discussion

“Most businesses know they have to automate—the question is how and when. With their extensive experience in automation, our panel will discuss the practical steps to getting started and how businesses can get the most out of automation and robot technology, including how to source reliable subcontractors.”

- Peter Williamson, CEO, Automate UK

- Søren Peters, CEO, Howtorobot.com

- Mike Wilson, Chief Automation Officer, Manufacturing Technology Centre (MTC)

- Troy Barratt, CEO, BAMUK Group

Efficiency, automation and adaptation in manufacturing

Thursday 6th June @ 15:00 | Manufacturing Insights Theatre – Panel Discussion

“Where will AI optimise manufacturing processes? How digital twins are transforming the manufacturing industry “

- Sandeep Dinkale, Senior Business Analyst and Product Lifecycle Management Consultant, Jaguar Land Rover

Meet the Sponsors:

Registration Sponsor: Turkish Machinery:

- Stand: D75

- www.turkishmachinery.org/En

Machinery Exporters’ Association (Turkish Machinery) represents and promotes the interests of its 18,000 members. It does so by coordinating and delivering sector-specific networking opportunities, business intelligence, and international events and trade missions.

The Turkish machinery sector has recorded robust growth over the past decade and has increased by more than 400% since 2003. It is now Turkey’s second largest exporter, worth some $25.5bn in 2022 – equivalent to 10% of total exports.

Centrally situated between Europe and Asia, Turkey is ideally located close to several of the highest-growth industrial machinery markets. Turkish machines operate in more than 200 countries around the world with a particularly strong presence in the US and Europe.

Buyers are drawn to the strong emphasis Turkish machine manufacturers place on R&D activities, the rapid adoption of international manufacturing standards and new technologies, a highly educated and skilled engineering workforce, and highquality aftersales support.

Bag Sponsor: Onmidex

- Stand: B76

- www.omnidexcn.com

Omnidex is a British owned, single-source provider for a range of metal and plastic fabrication, casting, machining, finishing, assembly and other manufacturing services from concept to completion.

Driven by a passion for quality for more than 20 years, Omnidex has provided world-class engineering outsourcing services at a competitive price. Its experience and expertise spans almost all sectors, including aerospace, automotive, consumer products, medical, oil and gas, and more. With customers in the UK, the US, South Africa, Australia and many more, Omnidex is a global business.

Underpinned by its highly skilled engineers and supported by a vetted network of subcontractors and stringent quality control processes, the company invests regularly in the latest equipment and technologies to deliver cutting-edge, high-quality products and services to its customer base.

Lanyard Sponsor: NOTE UK

- Stand: B61

- www.note-uk.co.uk

NOTE produces PCBAs, subassemblies and box build products. NOTE is a competitive EMS provider and stable business partner to customers with high standards. NOTE’s products are embedded in complex systems for electronic control, surveillance and security, for example.

NOTE’s business model builds on delivering high end manufacture, custom logistics solutions and consulting for the best possible total cost through long-term customer relationships and partnerships. Its customer offering covers complete product lifecycles, from design to after-sales. Primarily, its customer base consists of large corporations operating on the global market, and enterprises whose main sales are in northern Europe.

NOTE has a presence in Sweden, Finland, the UK, Estonia, Bulgaria and China. Sales over the last 12 months were SEK 4,201 million, and the group has approximately 1,600 employees.

Badge Sponsor: Made Smarter West Midlands

- Stand: E77

- www.cwgrowthhub.co.uk

Made Smarter West Midlands is aimed at Connecting manufacturing and engineering businesses with digital technology to transform the way they work and improve their productivity.

Coventry and Warwickshire (CW) Growth Hub, on behalf of the West Midlands Combined Authority and the Department for Business & Trade, leads the programme alongside Business Growth West Midlands and the Worcestershire, Stoke-on-Trent & Staffordshire, and The Marches Growth Hubs.

Made Smarter West Midlands also collaborates with a range of strategic partners, including the Warwick Manufacturing Group (WMG) at the University of Warwick and the Manufacturing Technology Centre (MTC) in Coventry, who help programme participants benefit from the expertise of their digital manufacturing specialists.

VIP Lounge Sponsor: Qimtek

- Stand: E67

- www.qimtek.co.uk

Qimtek proudly host 250 UK-based subcontract engineering suppliers, alongside 4,000 registered manufacturing buyers hailing from diverse industries. Our acclaimed Drag, Drop, Source! service is here to unite them all seamlessly.

Unlike traditional on-demand manufacturing platforms, Qimtek firmly believe in direct communication with your suppliers. No middlemen or barriers in your way; just a clear and transparent route to connect with new suppliers right from the project’s inception. Forge lasting partnerships with manufacturers you can trust.

Registration is Free!

Don’t miss out on Subcon 2024! Registration is completely free, offering an invaluable opportunity to connect with industry leaders, explore cutting-edge innovations, and participate in a variety of sessions designed to drive your manufacturing capabilities forward. Register today and discover your next manufacturing solution.