In response to demand for more efficient and cost-effective material handling systems, Interroll offers the patented MSC 50 magnetic speed controller. Easy-to-install into gravity roller conveyors and maintenance-free, the MSC 50 boasts many features that together, deliver process reliability and attractive ROI.

The first of its kind in the industry, the MSC 50 is technically superior and the most cost-effective solution currently on the market for controlling the speed of boxes, containers and plastic trays travelling on decline gravity roller conveyors and spirals or the end sections of sorters. Suitable for handling goods weighing between 0.5 kg and 35 kg (1lb-77lbs), the innovative system ensures lightweight packages move smoothly, while limiting the speed of heavy goods travelling along the conveyor to ensure safety and avoid product damage. These features make MSC 50 the perfect choice for warehousing, e-commerce, postal service, food and pharmaceutical operations, as well as for customers that use flow racks for heavy containers.

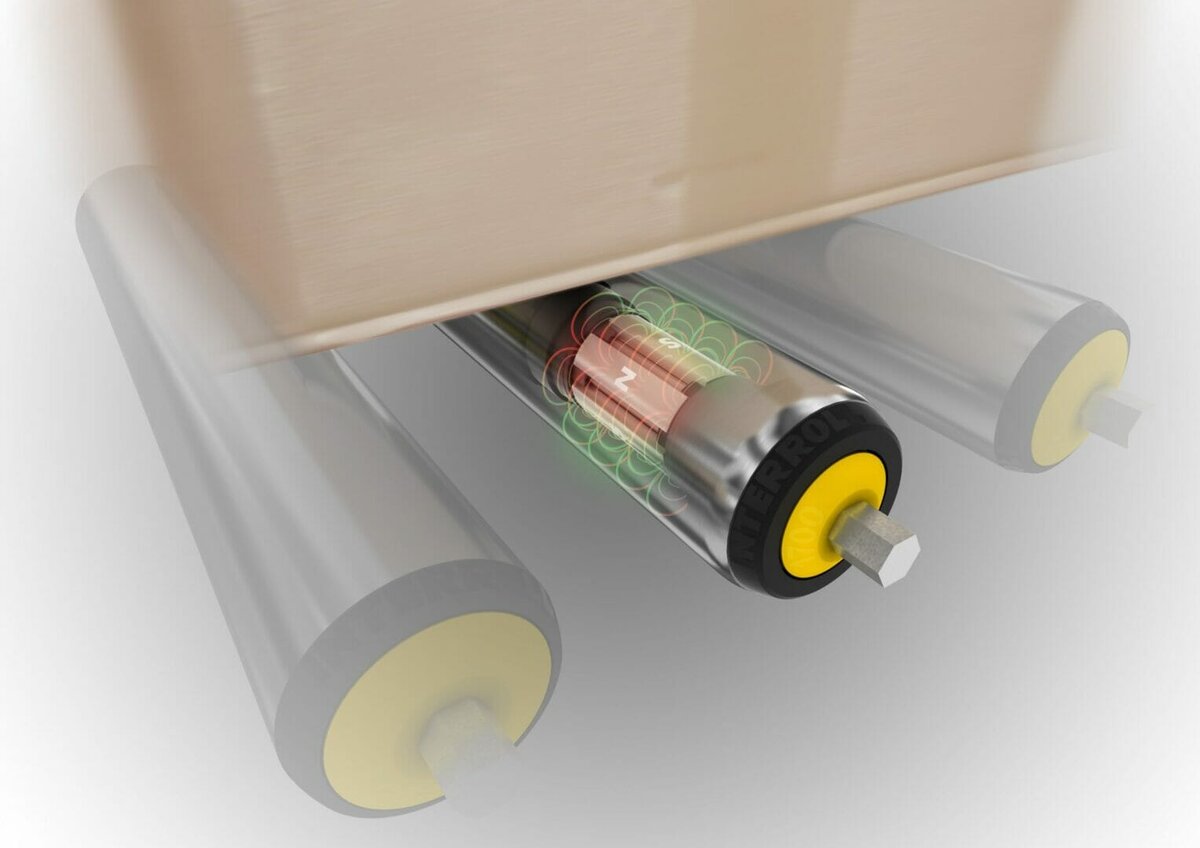

Many of today’s gravity conveyors have limited functionality as they are sold without components to control conveyor speed, mainly to minimize costs. However, because of an increasing diversity in the size and weight of goods running on gravity conveyors, Interroll saw a need to develop a speed controller. The MSC 50 features an eddy current brake that makes it maintenance-free and double shielding completely prevents magnetic emissions. It is easy to install and because of its bi-directional braking function, it cannot be mounted incorrectly. Different MSC 50 lengths and quantities can be used to scale the design and provide the ideal solution for your application or can be used for retrofitting existing gravity conveyor installations.

Full technical specifications are available on request or visit the website www.interroll.co.uk