INEOS Styrolution, the global leader in styrenics, announces today that it will exhibit the latest research results on its composite StyLight® at the Composites Europe in Stuttgart (November 6 – 8, 2018). Visitors are invited to meet with INEOS Styrolution experts in hall 9 at booth B59 to discuss product properties and explore the material for new applications, in particular in the automotive, electronics and sports industries.

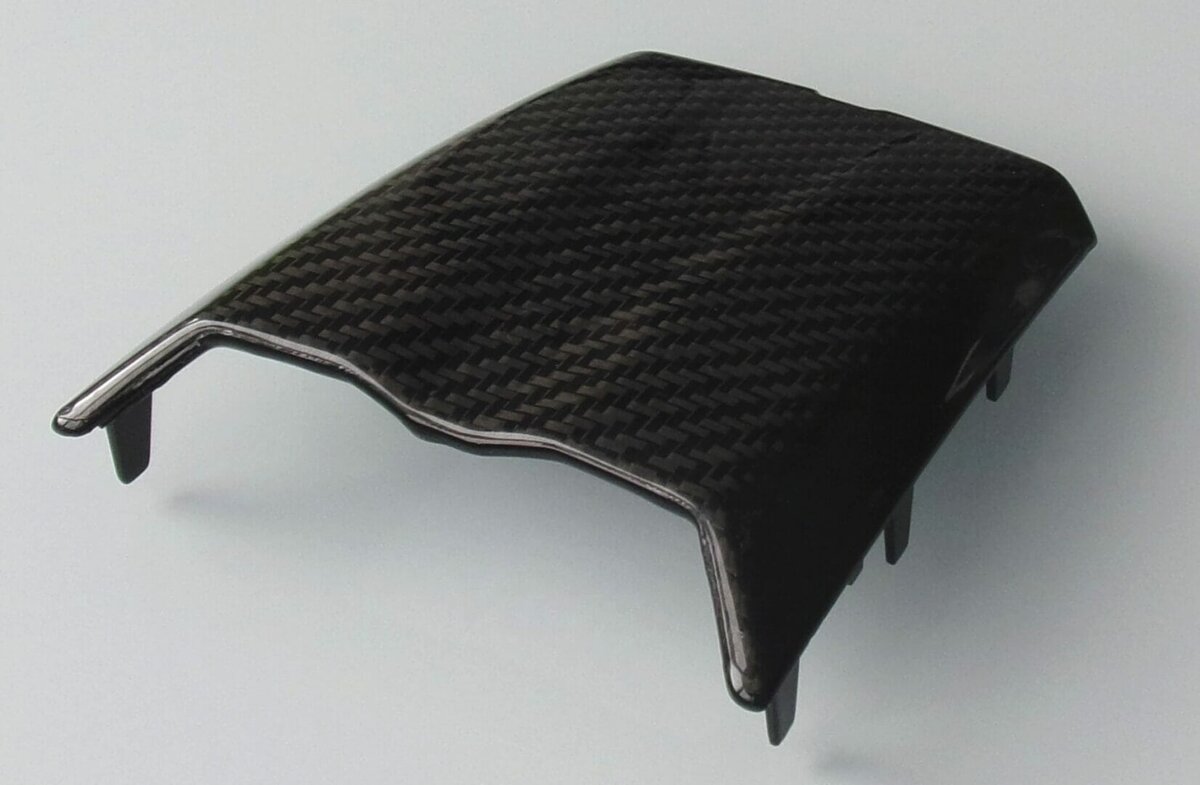

In 2017, INEOS Styrolution presented StyLight® applications for the first time at Composites Europe. Since that initial presentation, INEOS Styrolution has put a focus on analyzing the production process, determining optimized process parameters for various surface types and giving customers guidance to take advantage of the material in new application designs, e.g. in the automotive industry. An example is based on a center console part manufactured by ARRK Shapers’, a producer of carbon inner trims for the automotive industry.

Different surfaces, typical for automotive interior applications, were looked at and respective process parameters were determined for surfaces including leather grain, rough grain, high glossy surface, technical grain and fine grain. In total, around 120 different compression moulding process setups were tested to finally determine optimal process conditions.

In addition, the process parameters for in mould decoration (IMD) with foils from the company Leonard Kurz were evaluated and suitable foil types were identified.

The processing by injection moulding was optimised in parallel on the same 3D shaped part, back moulded with ribs and edge enclosure. The investigation resulted in valuable information in process parameters and suitable injection grades with given demonstrators. INEOS Styrolution’s efforts have resulted in leading European car manufacturers approving the material for new application designs.

Pierre Juan, VP Future Business and Innovation, comments: “2018 was a great step forward for StyLight. Customers benefit significantly from our research to optimise their respective production processes. They also have an advantage compared to thermoset composites based on epoxy resin. And, of course, I am very thrilled by the positive response of the automotive industry. The cooperation with ARRK Shapers’, for example, recently led to the full validation of StyLight according to the automotive interior specification of leading car manufacturers.”