Recently launched by Riftek LLC, the optoelectronic measurement and systems manufacturer – and available

with full support from its UK and Ireland distribution partner Ixthus Instrumentation, the new RF627WELD

laser seam tracking and measurement system enables precise control of the welding head position in robotic

welding systems. The system harnesses the advanced features of Riftek’s Lamia application software, a

choice of three РФ627Weld series 2D laser scanners to suit the required measurement area, and the RF017

series controller (or alternatively a PC) that interfaces with the customer’s welding controller.

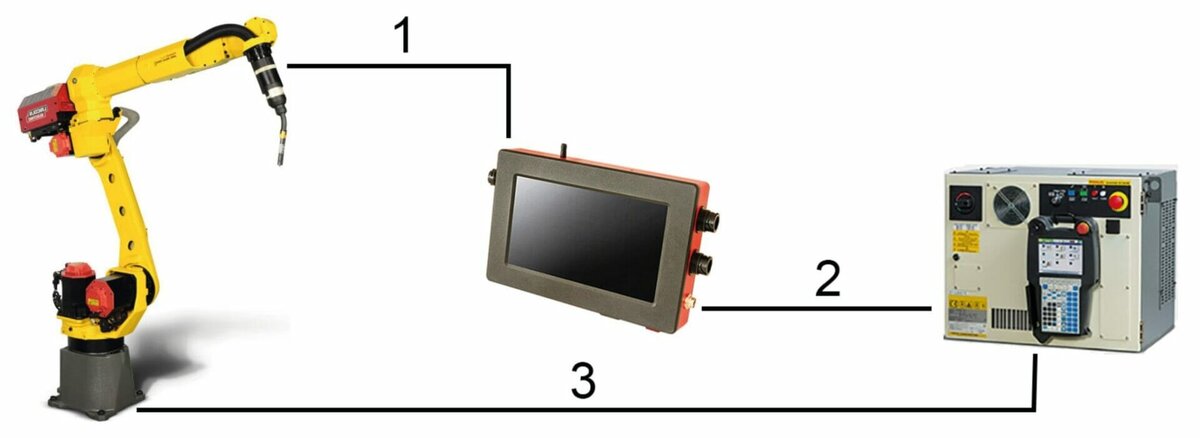

With the laser scanner mounted on the customer’s welding robot close to to the welding torch the

scanning area, located directly in front of the welding electrode, is pre-calibrated with a supplied

calibration plate. Riftek’s Lamia software processes the 2D positional information received from the

scanner to determine the exact coordinates of the welding joint which are then transmitted to the

robot controller in real time. In this way the robot controller is able to precisely align the position of

the welding torch during the welding process.

Three РФ627Weld series laser scanners feature Class 2M lasers offering various 2D scanning

areas from around 22 x 24 mm to 65 x 180 mm. Linearity through each range is up to +/- 0.1% in

Z-axis and +/- 0.2% in X-axis. Optional red or blue laser sources allow use with different welded

materials and temperature ranges, and various operating modes allow working frequency changes

for optimal sampling rates. With an IP67 sealed aluminium air or water cooled housing, changeable

toughened glass windows and a splash guard included these laser scanners are based on the well

proven RF627 range that guarantees durability and offer vibration, shock and temperature ratings

that meet the demands for heavy industrial use.

Riftek’s multifunctional Lamia software application is designed to be used to interface its laser

scanning range with automated industrial systems to provide recognition, tracking and

measurement of geometric parameters or objects in real time. Perfectly suited to welding joint

detection or for surface and dimensional profiling on a wide range of industrial processing tasks,

the software interfaces with the client controller to transmit scanning results and data visualisation.

Riftek offers a choice of protocols for communication with most common industrial robots. For the

RF627WELD system a selection of weld seam templates combine with control algorithms for seam

position recognition and corresponding location of joint coordinates.

Riftek can supply its own RF017 series industrial controller as a Tablet PC with Lamia software

installed or a customer supplied PC can be used. Cable options for connecting the RF017 or PC to

the Riftek laser scanner are included along with an RJ45 cable for Ethernet interfacing the robot

controller. The RF017 includes Wi-Fi so that a remote desktop or access point can be facilitated.

For system set-up, diagnostics and calibration, a detailed manual is available – free of charge and

prior to purchase – from Ixthus Instrumentation who provide complete technical support for the

RF627WELD system as well as Riftek’s comprehensive range of 2D laser scanners, laser

triangulation sensors, speed and length sensors, railway and other measurement instrumentation

systems. Ixthus Instrumentation works closely with Riftek and many other leading instrumentation

component manufacturers to supply sensors, transducers and complete systems for the

measurement of displacement, force, torque and vibration.