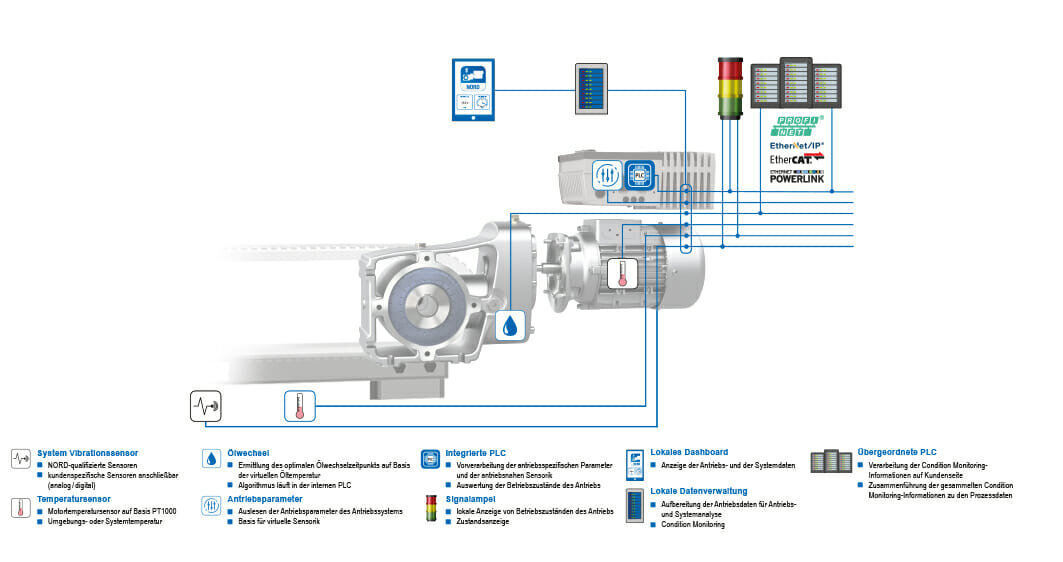

The system from NORD DRIVESYSTEMS regularly or permanently records drive and status data in order to optimise the operational safety and efficiency of machines and plants. Based on this information, concepts for predictive maintenance can also be developed. Fast, efficient and comprehensive evaluation of analogue and digital data (measurements, signals and operating parameters) by the intelligent PLC in the drive electronics forms the basis.The objective of predictive maintenance is to maintain machines and plants proactively and to detect changes at an early stage, to reduce downtimes and to increase the efficiency of the entire plant. A status-oriented maintenance replaces the traditional time-based maintenance. The detection and avoidance of impermissible operating states at an early stage avoid unplanned downtimes and machine failures. Predictive maintenance enables plannable machinery and plant downtimes based on real drive and process data. For plant and machinery operators using drive technology from NORD DRIVESYSTEMS, this results in a reduction of service and material costs as well as increased plant availability. Further advantages are a longer service life of components and machinery as well as a plannable and cost-optimised maintenance.

Intelligent algorithms use drive data

NORD DRIVESYSTEMS uses a drive-based approach where intelligent algorithms and virtual sensors transfer information from condition monitoring to predictive maintenance. An example is the sensorless determination of the optimum oil change time based on the oil temperature. This is based on the fact that the oil temperature is a key factor for oil ageing in gear units. This information in combination with available gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time. A physical temperature sensor is not required. The pre-processing of drive data using intelligent algorithms takes place in the NORD frequency inverter’s integrated PLC that is used as an evaluation unit. The customer can access the calculated data via all common interfaces.

The right PLC software architecture for each solution

The drive equipment can be optionally extended and adjusted to the respective automation task. Customers can select what tasks (drive monitoring, drive control, process control) they want to directly shift into the drive. In smaller production areas, this scalability offers the possibility to gain first experiences before reorganising the plant. There are three configuration levels available. At the first level, the drive unit PLC only performs the drive monitoring. The drive parameters are pre-processed in the PLC and communicated to the higher level control system that is responsible for drive and process control. At the medium level, the PLC integrates the drive control and also runs drive-related functions. At the higher configuration level, the inverter PLC completely replaces the higher level control system. Apart from the communication to a control unit, a local data management without internet connection can optionally apply the data.