13 January 2020 – Metal fabricator, Concept Metal Products Ltd, has invested in an additional Kimla machine to boost its 10-metre metal cutting offerings.

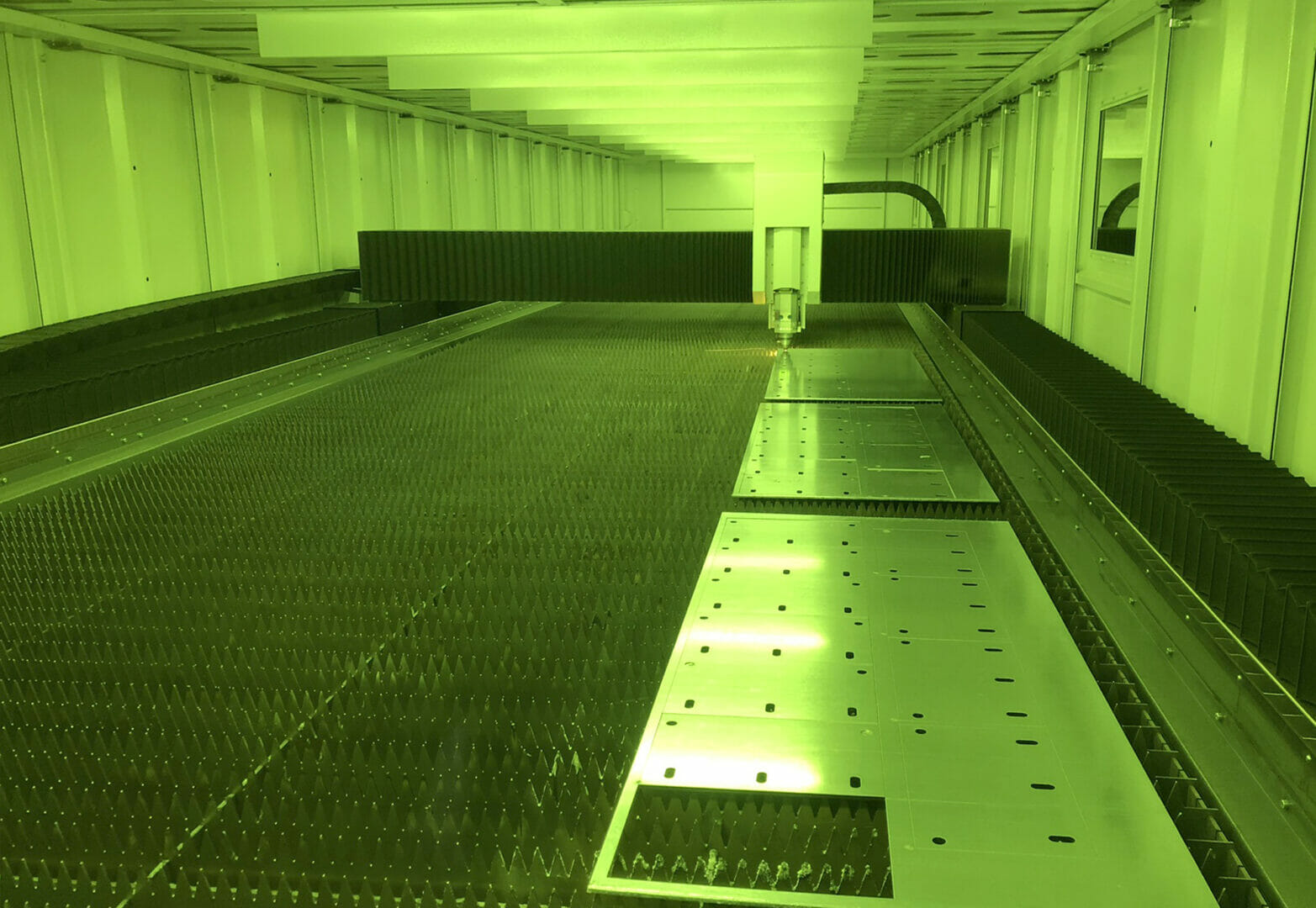

Having already purchased a 4kW 10m x 2m and a 6kW 4m x 2m Kimla fibre laser, the metal fabricators invested in the third machine to increase its metal cutting capabilities. The 6kW 10m x 2m machine will be installed in the factory by MBA Engineering later this year.

As one of the only companies in the north west of the UK to cut and bend up to 10 metres of metal, Concept Metal specialises in fabricating larger items for a range of different industries including highways, rail, nuclear and waste management.

Dean Barnard, general manager at Concept Metal Products Ltd, said: “Being able to provide a larger scale of laser cutting capabilities to our customers and a range of industries is a huge benefit to us. It’s great to be able to offer these services with the high level of efficiency and precision that comes hand-in-hand when working with Kimla machines.

“As this is our third laser cutting machine investment, we needed a machine able to manufacture long parts as this is something only we can offer in the north west. Combined with our LVD tandem press, capable of forming parts up to 9000mm long with first bend depth up to 605 mm, the additional Kimla laser cutter will assist in boosting this area of the business.”

Bradley McBain, managing director of MBA Engineering, also commented on the investment: “As the UK agent for Kimla, we strive to provide the best possible service to our customers by finding them the perfect machine to suit their needs and can create bespoke machines where needed. This is another example of how we deliver solutions to match a company’s business strategy rather than just an off the shelf solution.”

Established in 2009, MBA Engineering is the exclusive distributor of Kimla laser and waterjets in the UK.

More information about MBA Engineering, its services and its partnership with Kimla is available at www.mba-eng.co.uk.