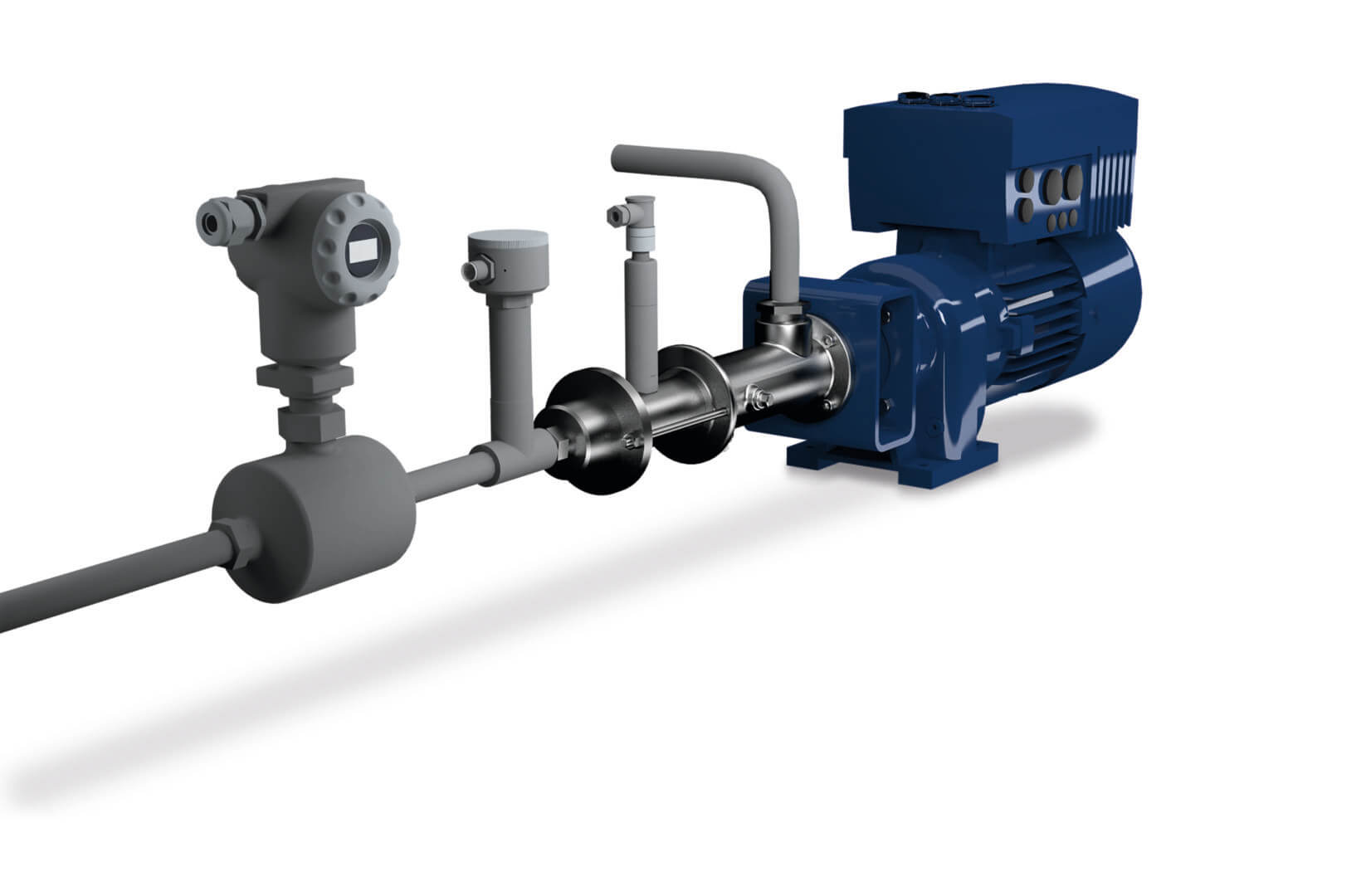

The Smart Dosing Pump (SDP) comprises a progressive cavity (PC) pump with an intelligent drive and associated controls. This combines the advantages of PC pump technology with enhanced control and monitoring within the pump, enabling customers to input one parameter – the proportional flow ratio – which the pump monitors and adjusts automatically.

Operation is simple; the SDP has an intelligent inverter drive which is programmed either locally via an HMI or centrally via a fieldbus interface. The SDP can also be controlled via analogue/digital I/Os either locally or remotely by a PLC.

The flow rate, once set, is monitored and controlled entirely by the pump drive which adapts to variations in operating conditions to ensure accurate repeatable dosing of even the most viscous products. Dry running and over pressure sensors feedback to the drive and protect the pump from damage.

As well as being simple to set up and adjust the SDP incorporates all of the advantages of PC pumps for dosing of chemicals:-

- Accurate linear flow – directly proportional to pump speed

- Low pulsation flow – pulsation dampeners not needed

- No ball valves to stick

- Chemicals with solids, which are corrosive and abrasive, can be handled

- Thin to high viscosity products can be pumped

- Easy calibration – no calibration pots needed

- Suction lifts up to 9m

- Discharge pressure up to 24bar

- Turndown ratio of over 3000:1 using the Dosing pump range

Smart Dosing Pumps are available on pre-wired skids, instantly ready for installation and integration within central systems.

The accuracy of both batch and continuous flow is ensured, saving money on chemical use, and the efficient operation of the pump ensures the lowest life-cycle costs are incurred.

Contact SEEPEX at sales.uk@seepex.com or on 01935 472376 for more information.