Over the course of the past few months COVID-19 has taken the world by storm. With “stay at home” orders effectively placing everyone in a sort of quarantine, we’ve all had to adapt to accommodate some major changes in the way we live our “normal” everyday lives. It’s certainly been difficult to navigate. While a large part of the population is working from home, there’s also plenty of people who work for an essential business, such as manufacturing or distribution facilities, and still go to their place of work every day.

Operations and facilities manager are now faced with the task of assessing their current processes, reducing employee contact and interaction and adjusting to the changing guidelines. We’ve heard this term “social distancing” for weeks, maybe even months now, and it seems like it’s here to stay. It’s a simple concept – maintain a 2 meter distance between you and the people around you. But in a manufacturing or distribution facility, we’re talking about 10, 20, 30…up to hundreds of people, who must do their job in a designated work zone and maintain social distance. Adjusting a facility to accommodate these changes can be quite the undertaking. The spread of this virus impacted our communities fast and it’s important to be prepared for this ongoing threat in case we see a second wave in the future.

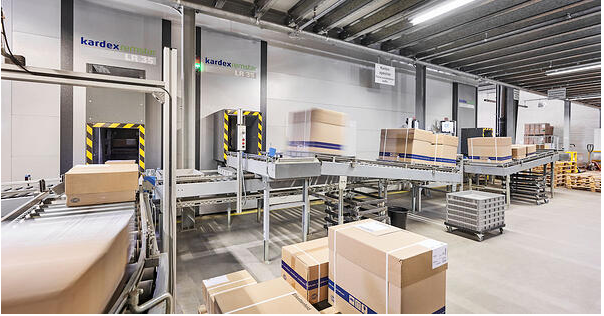

Designed on the goods-to-person principal, ASRS bring stored parts to the operator with the touch of a button. This allows the operator to remain in one area to pick parts instead of spending time walking up and down aisles searching for parts. Not only do these systems provide workers more distance from one another, they increase productivity by eliminating the time spent walking up and down aisles to search for stored items. Automation keeps workers safely within their assigned workstation, less fatigued and more productive. Installing an automated storage and retrieval system can in some circumstances even reduce labour requirements by as much as 66%, enabling current workers to be reassigned to new tasks (such as cleaning and sanitising) while easing hiring pressures and labour expenses.

In addition, goods-to-person picking systems can also speed up item picking for a boost in throughput, yielding higher rates of product picked or moved through the facility within a given period of time. This allows an operation to extend order cut-off times, so more orders can be filled within a day, or to pick up to 400% more items with the same number of workers during the same amount of time.

With the UK government recommending social distancing to prevent the spread of COVID-19, automated storage and retrieval solutions can support social distancing in the warehouse, we have created a white paper on how implementing automated storage and retrieval systems (ASRS) can help support social distancing in the warehouse. Download the white paper or contact us at [email protected]