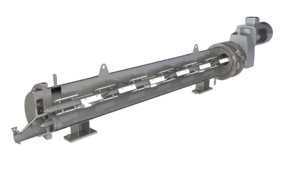

Scraped surface heat exchangers are commonly used for the thermal treatment (heating, cooling, pasteurisation, evaporation, etc.) of products and materials with a high fouling potential, such as viscous foods, slurries, etc. The most common type features rotary scrapers within a tube, but within this basic variation there are many different designs. HRS Heat Exchangers has created its unique R Series of rotating scraped surface heat exchangers from scratch to provide excellent heat transfer and performance.

The range R Series of heat exchangers was designed without reference to existing types of scraped surface heat exchangers (SSHE), in order to overcome the problems associated with such designs. As a result, the HRS R Series of SSHEs boasts a number of unique features:

- Patented helical blade scraper bar design

- Unique gearbox design to reduce noise

- Multi-tube options to reduce footprint, energy consumption and operating costs

- Unique sealing system to allow removal of individual tubes

Why use SSHEs?

The main reasons for specifying SSHEs are to prevent product build up on the surface of the tube (which reduces thermal transfer) and to improve the mixing (and therefore the homogeneity and effectiveness of heat transfer) within the product or material being treated. As such they are commonly used for viscous food products such as creams and sauces, and for high fouling waste products such as slurries.

However, because of the increased resistance within the tube, SSHEs can create much higher pressure drops than open tube heat exchangers. A higher pressure drop means more pressure (and therefore more energy) is required to operate the equipment. The HRS R Series of SSHEs has a unique design to reduce this pressure drop.

The patented R Series helix

SSHEs typically consist of two key components within the tube: the scrapers, which rotate around the inside surface of the tube to remove fouling, and a mechanism (known as the scraper bar), which holds and drives the scrapers.

The HRS R Series uses a unique helical screw, which resembles an auger wrapped around the scraper bar. The key to this patented design is the gap between the edge of the helix and the tube surface, which provides three important benefits. Firstly, the pressure drop is reduced along the heat exchanger, particularly for difficult high viscosity products. Not only does this reduce energy consumption, it also helps to maintain product identity and quality The second benefit is that the gap increases turbulence at the tube wall, helping to reduce fouling and improve mixing.

Finally, the helix can be used to recover product (either by running through the system or running the helix in reverse). Depending on the product and configuration of the heat exchanger, up to 90% of product can be recovered.

Details make the difference

While the patented helix is the main feature of the R Series, there are several other unique design elements which make it superior to other SSHEs. The R Series is available in both single- and multi-tube versions (containing three and six tubes per units). The multi-tube versions use a single motor and gearbox, helping to reduce running and installation costs, reduce operating complexity and reduce the overall footprint. Furthermore, thanks to a unique sealing system, individual tubes can be removed for cleaning or inspection, meaning that servicing is quick, and parts do not need to be sent away for rechroming. Key low-cost spares can be held on site and replaced quickly and easily.

A unique gearbox design reduces operation noise, making the R Series ideal for working environments such as food factories, while standard features include a hygienic stainless-steel construction, and units which are fully insulated and cladded.

- The key to the HRS R Series of rotary scraped surface heat exchangers is its helical scraper bar design

- The HRS R Series is available in single (right) and multi-tube (left) versions

Versatile R Series

The R Series has also proved incredibly versatile since it was first designed. As well as the standard single- and multi-tube versions, an ATEX version for use in explosive atmospheres and the oil and gas industry has been developed. A heavy-duty version (RHD Series) is also available for particularly viscous materials like nut butter and fats, as well as a multi-pass version (RMP Series) where a large heat transfer area is required in a small footprint.

Trial units are available for testing and evaluation around the world, and the engineering and development team at HRS continues to develop and adapt the R Series for new applications and processes.