The GTMA has identified over 500 UK-based companies across the country working in 3D Printing (3DP) / Additive Manufacture (AM) as a core element of their business operations. Many more are using the technology and optimizing design of components to maximise the benefits of moving to this technology as a route to production.

We have recently undertaken a survey of the UK-based 3D Printing (3DP) / Additive Manufacturing (AM) community to gain an insight to what is happening around the country. Unlike more traditional forms of manufacturing this technology is not clustered geographically, the technology being so flexible that it can be done in any location by small teams and individuals without necessity for supporting infrastructure. Naturally there are significant numbers of 3DP/AM companies in areas around Universities at the forefront of the development and promotion of the technology.

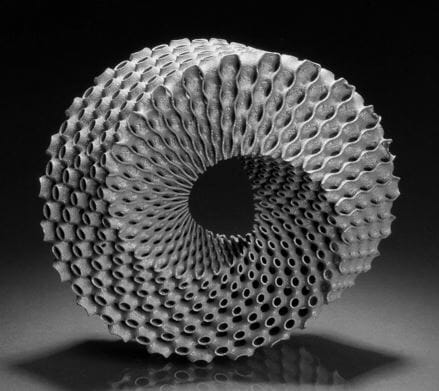

Key findings from the survey include significant adoption of metal powder as a building material. The early days of commercial adoption was based around resins, plastics, and other synthetic polymers including binders for building sand casting cores. This growth of metal powder manufacture reflects improvements in the processing technology, availability of a wide range of metal alloys, and commercial demand. From the survey findings over one third of material suppliers to 3DP/AM companies are offering metal powder; and over half the companies responding to us are producing metal components and tooling. There is also indication that other materials including Kevlar and carbon fibre are being adopted.

Alongside the growth in metal 3DP/AM there is an increased requirement for CNC machining, for finishing and support removal. This brings the two industries closer and delivers maximum value to the end customer.

As the 3DP/AM technology becomes more widely adopted and better integrated with other manufacturing technologies we will see further growth in metals manufacture and other high strength high value materials.

3D printing is playing a key role in demonstrating its ability to respond to the need for on-demand production and help alleviate supply chain disruption. Globally the industry has overcome the hype of the last decade to emerge as a viable manufacturing technology in its own right.

Within the nuclear industry the cost of large installations is growing while the cost of alternative energy is dropping. One way forward for nuclear power may lie in small-scale nuclear reactors, which overcome many of the drawbacks of larger reactors. Called Small Modular Reactors (SMR’s), these systems are expected to dramatically reduce construction timelines and will make nuclear more affordable to build and operate. The production of SMR’s requires new approaches to design and production of reactor parts, like enhanced part performance, more compact size, better heat management and shorter lead times. The design flexibility and part consolidation, exploit core attributes of AM. The more complex geometries possible with AM enable more compact sizes of parts and their subsequent increased performance. As existing nuclear plants age, it is becoming increasingly difficult to find replacement parts, their designs are virtually impossible to obtain. Many nuclear plants are more than 40 years old and many of the companies that made the original parts no longer exist. AM makes it possible to produce some of the missing spare parts using reverse engineering.

The GTMA is working with the Nuclear Industry Association (NIA) and AMRC Fit for Nuclear to identify supply chain opportunities and setting up a ‘Nuclear Cluster’ of member companies currently and wishing to operate in this sector. The central operations at Sellafield are in the process of ramping up works post-lockdown, activities during the recent months have been scaled down to cover only essential activity. We are in discussion with the senior Sellafield team to ensure we identify any contract opportunities. There is currently a call for the supply of fabricated containers for cooling rods, we can send you the specification on request to alan@gtma.co.uk

The UK Government has launched ‘Project Defend’, a review of the security and supply of critical services and products as we emerge from the COVID-19 pandemic. This emerging industrial strategy will include bolstering manufacturing supply chain capability in the Midlands and North of England. The focus will be on how to reduce reliance on one country or region, mitigating risk and ensuring resilience in the face of spikes in demand.

For further information please email alan@gtma.co.uk