By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Heat exchangers are crucial to many processes in the water industry, whether as part of an aerobic or anaerobic digestion plant, for cooling or evaporation, and for sludge concentration. There are a number of different types of heat exchanger available and choosing the right one can appear daunting. For both economic and environmental reasons, maximising productivity is essential in order for companies to remain competitive, and correct heat exchanger selection is key to this.

What is productivity?

Productivity is measured by the ratio of output per unit of input. Many water companies see it as a balancing act – how can they increase their output without increasing their costs? It is closely linked to efficiency, ensuring that every piece of equipment and every part of the process is optimised, delivering greater value for money to the operator.

Understanding the process

The most important criteria when specifying a heat exchanger is to ensure that it will be fit for purpose. To do this, it is important to understand both the material being treated, the heating (or cooling) medium, and the process involved. Is the material in question liquid (dirty or clean water) or semi-solid (sludge)? Is it viscous? What is the extent of the temperature difference required?

Other information must be provided for correct heat exchanger selection, too. For example, does the product contain solid particles? Consider also whether it is shear sensitive, if the process needs a scraped surface heat exchanger (SSHE), or whether well-designed corrugated tubes will be enough to prevent fouling. Also bear in mind the space available for the heat exchanger, and the connection pipework and fittings. The more information an operator can provide, the more likely they are to get the right heat exchanger for the job.

Avoiding a false economy

After thoroughly researching the options available, it may be that that more than one type or model of heat exchanger is suitable for the purpose. In order to ensure optimum productivity, it is important to consider the total cost of ownership (TCO). Although some operators can be swayed by the initial purchase price, this can be a false economy. The lifecycle cost of a heat exchanger, particularly one used to process difficult materials such as sewage sludges, heavily depends on the costs of cleaning and maintenance – buying a cheaper design which is more prone to fouling can quickly become more expensive to operate. To keep productivity high, it is therefore essential to consider the TCO of a heat exchanger, not just the purchase price.

Energy efficiency

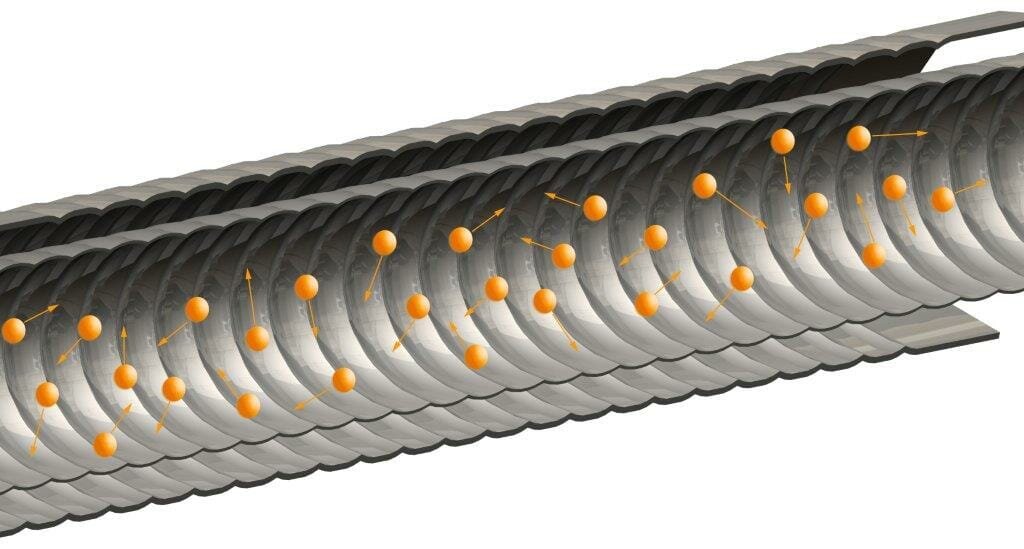

The running costs of a heat exchanger also have a large effect on its overall financial viability, so selecting a heat exchanger which is energy efficient is key to enhancing productivity. HRS Heat Exchangers have developed a number of features which are specifically designed to improve the operational energy efficiency of both their tubular and scraped-surface heat exchangers. These include the use of corrugated tubes specifically designed for high fouling sludges, such as the DTI Series of Double Tube Heat Exchangers, and unique SSHE designs including the Unicus Series.

The Unicus Series is based on traditional shell and tube heat exchangers, with the addition of a patented stainless-steel scraping mechanism which is hydraulically moved back and forth within each interior tube. This movement minimises potential fouling of the product by keeping the tube wall clean, and also creates turbulence within the material. Both of these actions help to increase heat transfer rates and together, they create a highly efficient heat transfer process ideal for high fouling viscous materials like sludges.

Maintenance matters

Using the wrong heat exchanger can soon prove costly in terms of maintenance and spare part costs. In fact, HRS have been asked to replace a number of alternative heat exchanger designs in the wastewater sector when they have become too expensive to clean and maintain. All HRS heat exchangers are designed to make cleaning and maintenance as easy and flexible as possible, while their clever design reduces cleaning and maintenance intervals.

The fact that HRS equipment can be remotely monitored also makes it easier to anticipate problems, enabling predictive maintenance. Being able to quickly identify issues helps to keep efficiency high and provides more time to plan for maintenance, resulting in less downtime for operators.

Beware hidden costs

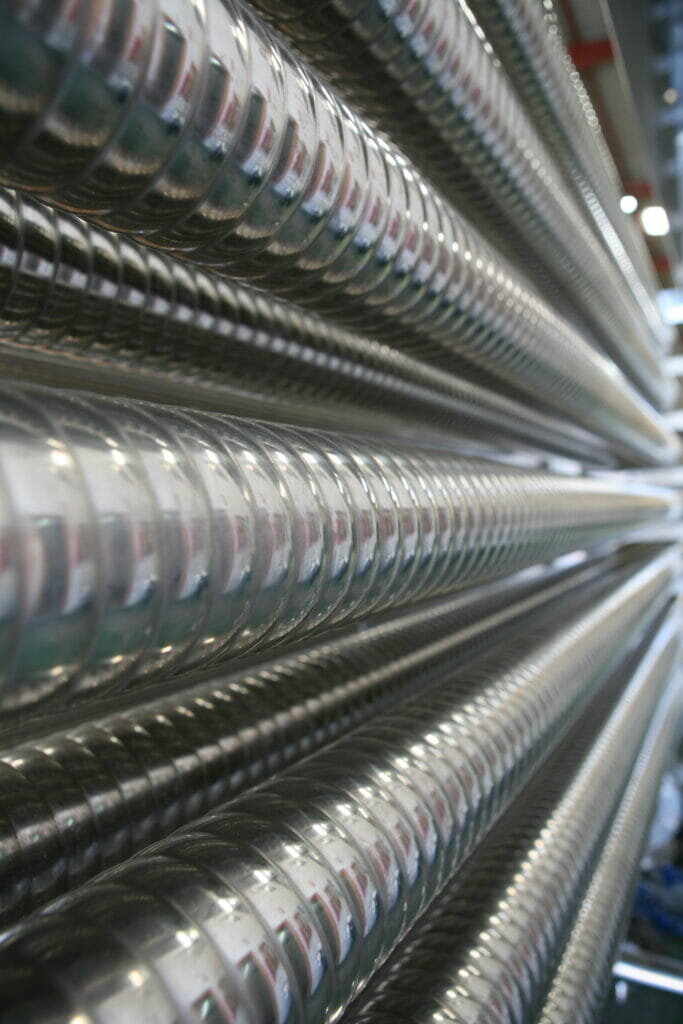

Another consideration is the overall installation costs, and whether fitting the heat exchanger will require the purchasing of ancillary equipment. The corrugated design of HRS’ tube-in-tube heat exchangers results in improved efficiencies, providing comparable thermal performance to other designs, but in a smaller footprint. These can often be skid- or frame-mounted, reducing the need for significant support infrastructure. Both standard clamp and flange fittings are available, although any bespoke fitting can also be supplied.

A balancing act

While a low purchase price may appear attractive, with much of the TCO coming from running costs, keeping these lower over the lifetime of the heat exchanger will provide a greater return on investment in the long run. Whatever solution you choose, make sure to consider its energy efficiency, maintenance requirements and the costs of any ancillary equipment before signing on the dotted line. Put simply, specifying the wrong heat exchanger could decrease your productivity – choosing the right heat exchanger will almost certainly increase it.

- HRS Unicus Series scraped-surface heat exchangers minimise fouling in sludge processing systems

- Using corrugated tube heat exchangers reduces fouling and improves energy efficiency

- The corrugated tube design of HRS tube-in-tube heat exchangers minimises fouling and increases efficiency

- Matt Hale, International Sales & Marketing Director at HRS Heat Exchangers