(3rd September 2020, Tel Aviv, Israel) When it comes to the manufacture of miniature, low cost tunable Near Infrared (NIR) filters, Unispectral, a Samsung-backed company based in Ramat Gan in Israel, is revolutionising the IR inspection market.

Unispectral’s products add a biometric layer to authentication camera systems, improves facial authentication, enables camera-based material detection and spectrum-based image segmentation and object classification, identifies bank notes and documentation, captures unseen to standard cameras defects in products, coated, electronic and optical parts, detects vital signs for remote medical, and diagnoses plants stress in the field. With unprecedented cost reduction over other spectral cameras, Unispectral is removing the barrier for new mass market adoption of low cost, miniature spectral IR camera.

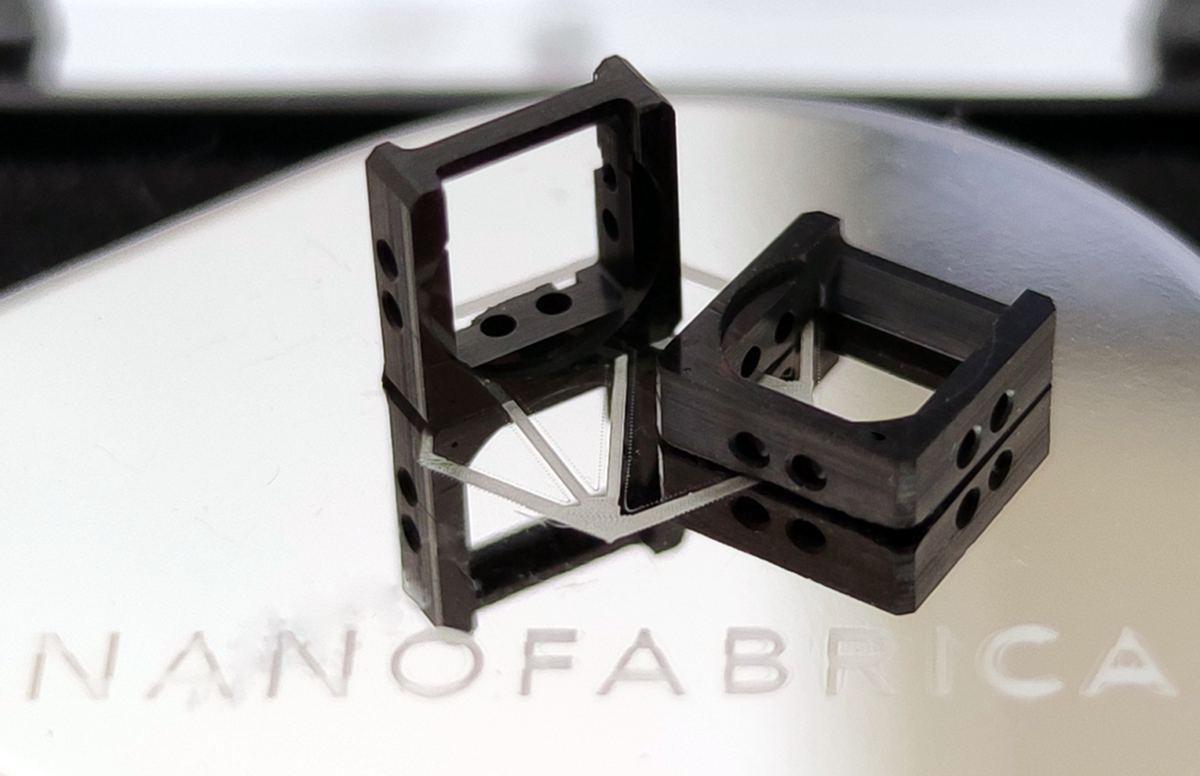

At the heart of the company’s solution is a tunable Fabry-Pérot filter made using MEMs technology, which is embedded in all cell phones. Peleg Levin, CTO at Unispectral explains, “It is this Fabry-Pérot filter that allows us to democratise hyperspectral imaging, and we can embed it in all different types of mobile phones. To be able to adapt the MEMs device to different image sensors in the various mobile phone on the market, we had to develop a proprietary adapter for the camera barrel, the adapter needing to be manufactured to 10-micron tolerances.”

Until connecting with micro-3D printing developer Nanofabrica, Unispectral used traditional injection molding technology, as this was the only technology that facilitated the mass manufacture of the adaptors at the precision required. However, using injection molding required a huge investment in time and money (the expensive tooling taking several months to fabricate).

Unispectral now uses the Nanofabrica Tera 250 system to make the adapators. Levin continues, “Nanofabrica is not only able to achieve that 10-micron tolerances that are required, but batches of hundreds of adaptors can be made in 6 hours. In the mobile phone market we have each year very rapid changes and development so we need to adapt quickly, iterate, adjust the design, and with the help of Nanofabrica’s technology we are able to adapt rapidly to various camera model designs. Since we intend to embed our device in mobile phones we are talking about millions of parts per year. We see that with Nanofabrica we can reach these numbers easily.”

Nanofabrica’s industrial micro 3D printing technology allows for the subtle redesign of the adaptor for different mobile phones without the need for expensive tooling. Any design tweaks can be made in the CAD model downloaded to the 3D printer, so mass customisation becomes a reality.

Jon Donner, CEO of Nanofabrica says, “We are excited about the results we have achieved with Unispectral. As we move forward 3D printing will continue to be used as a replacement for traditional manufacturing technologies, and this will continue to be focussed on applications where the use of 3D printing reduces the time and cost of manufacturing as is the case with the Unispectral adapter. 3D printing is no longer a technology that can only be used for one-offs or very short runs. The technology in general is now able to cater for mid-volume runs today, and at Nanofabrica in particular where we focus on the production of micro-scale parts and components, we can obviously fit numerous products in a single build envelope, so we nudge into the area of mass high volume manufacturing very easily. It is our feeling that as a general rule of thumb, for 3D printing to be used as a rapid manufacturing technology for any given application it will have to have demonstrate at a minimum a 10-fold improvement in cost and/or time savings to offset the cost and risk associated with changing over from a traditional manufacturing technology. For Unispectral this is absolutely the case, and proves that for them, 3D printing is a clear and efficient alternative to traditional manufacturing processes today.”

Existing at the interface of 3D printing for production and the industry-wide drive towards miniaturization, Nanofabrica’s industrial micro 3D printing technology lifts the lid for designers and manufacturers in their quest to embrace the inherent advantage of the technology, and enables them to exploit the ability that exists through 3D printing to build complex parts in small, medium, and high volumes in a timely and cost-effective fashion.

The technology is based around a Digital Light Processor (DLP) engine, but to achieve repeatable micron levels of resolution combines DLP with the use of adaptive optics. This tool in conjunction with an array of sensors, allows for a closed feedback loop, the reason that Nanofabrica’s Tera 250 can achieve very high accuracy while remaining cost-effective as a manufacturing solution. In addition, through rigorous R&D, Nanofabrica has managed to develop its own proprietary materials (based on the most commonly used industry polymers) which enable ultra-high resolution in parts built.

You can access the full interview with Peleg Levin and see the adapters manufactured on the Nanofabrica technology here.