~ Making your manufacturing systems cohesive ~

In 1969, Margaret Hamilton, director of software engineering for Apollo 11, was famously pictured standing next to a stack of paper containing the program listing that helped take the first team to the moon. Now, a 4GB phone has over a million times more memory than the Apollo 11 computer had in RAM. Here Russell Pursglove, software product specialist for industrial metrology provider The Sempre Group, explains the benefits of swapping reams of paper for automated quality management.

Keeping track of quality management data manually involves reams of paper, tedious filing and makes it challenging to access information when needed. Paper documents can easily be misplaced or overlooked, which could mean trouble if parts are not to specification or there are problems with quality later on. All in all, a problematic approach.

Yet, when we visit the facilities of British and Irish manufacturers, we often see huge filing cabinets of essential quality management documents like first article inspection reports (FAIRs) and product part approval process reports (PPAPs). In my experience, only around five per cent of manufacturers use automated quality management software, with the rest opting for paper or detached digital methods.

Crying out for change

Though one step up from managing everything on paper, isolated digital documents unnecessarily complicate manufacturers’ communications with their customers. Without a digital thread connecting drawing to product to report, the process can never be fully traceable. Customers can become confused about product quality, which can create a sense of unprofessionalism and drastically reduce the customer’s trust in the supplier.

Manually managing and auditing isolated drawings and models can waste manufacturers thousands of pounds of employee time and lead to human error — a very poor use of a valuable workforce.

Consider this example. A manufacturer is manually creating FAIRs, loading up metrology equipment, taking notes and saving the data in an Excel spreadsheet. Skilled staff are spending hours entering data into an isolated document that isn’t communicated properly across the business or supply chain, creating a lack of traceability. At a time when most manufacturers have an enterprise resource planning (ERP) platform available to connect digital systems, why would you use isolated documents or paper?

Finding a solution

Quality 4.0 makes data king. The journey to achieve Quality 4.0 includes automated data collection to improve reporting, storing and handling of information regarding product quality.

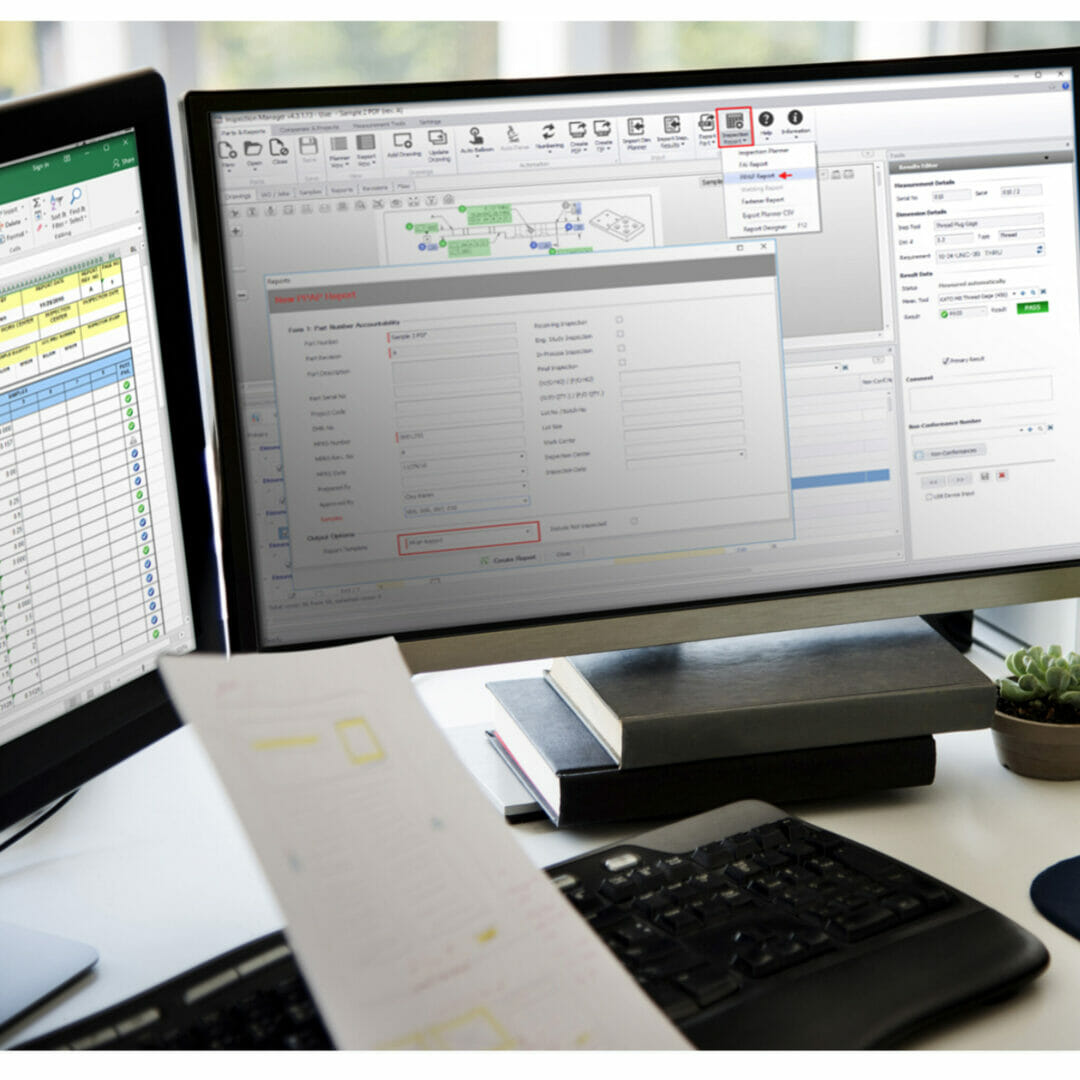

By taking a Quality 4.0 approach — using automated quality management software, plant managers can easily improve efficiency, productivity and quality. For example, using High QA, inspection managers can automatically identify geometric dimensioning and tolerancing (GD&T) from models or PDFs, identify critical dimensions and automate results and statistical process control (SPC) data to auto-populate reports.

Automated QMS tools offer manufacturers an all-in-one solution for quality management, collecting and storing data at every point, from drawing to final product. They eradicate the need for time consuming paperwork and filing, which means manufacturers can easily communicate important quality information across the supply chain and can remove the headache of compliance reporting. Manufacturers are able to get the best out of their workforce — a real asset during the pandemic where there may be fewer employees on site. The system can check for errors in digital documents, ensuring that they are always filled out right first time.

By implementing a Quality 4.0 approach, using paper to collect data will soon become as outdated as the reams of paper that got Apollo 11 to the moon. For more information about automated quality management software solutions, visit www.thesempregroup.com.