With Christmas around the corner, it’s now time to focus on the world’s oldest warehouse, the one where Santa is tirelessly packing millions of gifts. At his smart warehouse in the North Pole, Santa is using the latest Industry 4.0 technology to prepare for Christmas. Neil Ballinger, head of EMEA at automation parts supplier EU Automation, talked to Santa to understand which technologies he is using to automate his warehouse, and what manufacturers and supply chain managers can learn from him.

Like many of us, Santa is familiar with the challenges of global supply chains — speed, traceability and the necessity to accurately predict demand are just some of his headaches. There are roughly 1.8 billion children around the globe, which equals 25% of the world’s population. If the average gift weights 1 kilogram, Santa has to deliver 600 tonnes of presents in only one night. Such a task requires solutions like collaborative robots and an Internet of Things (IoT) system to build a resilient supply chain for global distribution.

IoT tracking systems

To maintain an updated customer database and keep track of orders, shipments, and inventory stock levels, Santa requires an incredible level of visibility across his supply chain. Luckily, an Internet of Things (IoT) tracking system can help him store and process data that can improve operations.

IoT asset tracking systems are vital for any distribution business as they reduce connectivity issues and ensure that every product is continuously monitored. Santa is not the only one to have realised the potential of this technology — by 2027, around 267 billion asset tracking devices will be deployed globally, reaching a market size of $3.93 billion by only 2023, according to a report by Thales Group.

Connected sensors and machine-to-machine communication protocols help warehouse managers get real-time updates at every stage of the supply chain. They provide useful insights on asset locations, temperature, functionality and send the data reliably and continuously from anywhere in the world. Not only will Santa be informed in real-time about the location of each toy, but he will also be able to track his sleigh’s fuel consumption and prevent any maintenance issues.

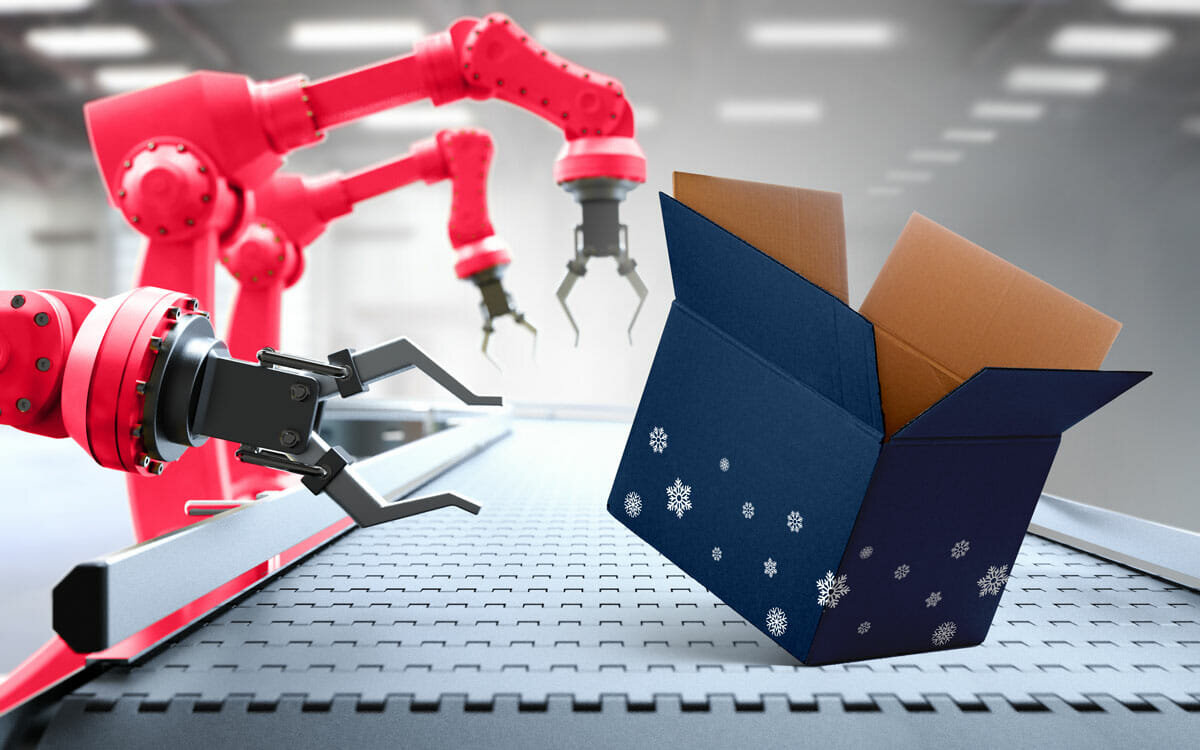

Collaborative robots

Collaborative robots are designed to optimise the workflow while allowing the warehouse to maintain its infrastructure design and processes. The market for collaborative robots was valued at almost $600 million in 2018 and is projected to grow to $7.5 billion by 2027, accounting for about 30 per cent of the industrial robot market, according to a report by Interact Analysis.

Some of the most innovative cobots are also very easy to programme, even for workers with no knowledge of robot programming, like the majority of Santa’s older employees. Sometimes the process involves only physically moving the robot’s arm to the correct location. This further reduces initial automation costs and contributes to the return on investment (ROI), because there’s no need to invest in training.

To demonstrate how automation can help with the festive season, Universal Robots employed two UR3e cobots to decorate a Christmas tree. These cobots are ideal for such scenario, due to their lightweight of only 11 kg, but also because of their 360-degree rotation ability on all wrist joints, and infinite rotation on the end joint. ABB also used twelve robots to decorate retail spaces in New York for Christmas. Its famous dual-arm YuMi® cobot was used to serve coffee and interact with humans to create a unique merchandising experience.

The flexibility of cobots is just as useful in a warehouse context, and not just to serve coffee to hard-working elves. Cobots reduce the physical workload of warehouse employees, resulting in fewer injuries and increased job satisfaction. Cobots can also guide workers to maximise their productivity — for example, they can use artificial intelligence and advanced machine vision systems to plan the best picking routes, eliminating unnecessary walking.

Collaborative robots and IoT solutions are no doubt the future of automation, providing reliability and efficiency while reducing costs as well. Nevertheless, as with all technologies, they are prone to technical issues that need to be resolved in a timely manner to avoid downtime. EU Automation provides new, refurbished and obsolete parts for a large variety of automation manufacturers. And just like Santa, we deliver quickly all over the world.

Whether they are based in the United Kingdom or at the North Pole, all warehouses need to invest in smart technologies to remain competitive and increase efficiency.

To find out more about the offerings for a smart warehouse at EU Automation, head to www.euautomation.com