Optical Surfaces Ltd has been selected by the Optical Engineering Group at the University of Warwick (UK) School of Engineering to supply key focusing optics to enable accurate 3D tracking and analysis of mosquito flight behaviour.

The UK Engineering and Physical Sciences Research Council (EPSRC) funded research project at the University of Warwick will utilise large field-of-view digital holography for accurate 3D tracking of mosquito flight in an elongated flight chamber. Using this video-tracking methodology, researchers will look to accurately quantify the effects on mosquito behaviour of a range of chemicals or devices proposed to eliminate them, thereby providing a valuable insight into their mode of action.

Professor David Towers, Head of the Optical Engineering Group at the University of Warwick’s School of Engineering said “By capturing the diffraction pattern of mosquitoes in a telecentric volume, we can mathematically refocus the scene to obtain their z-axis positions, and therefore record a time-series of accurate 3D coordinates for tracking and analysing their flight behaviour. To facilitate this optical set-up, we required large aperture off-axis parabolic mirrors to provide the wide collimated beam required to examine a large field of view in an optical set-up that resembles a z-type Schlieren interferometer.”

Matthew Hall, the project researcher said “We approached Optical Surfaces to supply these key optics because of their international reputation for producing high quality off-axis parabolic mirrors. We have been impressed by the knowledgeable advice provided by Optical Surfaces and their flexibility to offer competitive pricing on an ex-stock off-axis parabolic mirror that meets our performance requirements”.

Mosquito 2D flight patterns (courtesy: University of Warwick, Liverpool School of Tropical Medicine; Voloshin V, Kröner C, Seniya C, Murray GPD, Guy A, Towers CE, McCall PJ, Towers DP. 2020 Diffuse retro-reflective imaging for improved video tracking of mosquitoes at human baited bednets. R. Soc. Open Sci. 7: 191951. https://dx.doi.org/10.1098/rsos.191951)

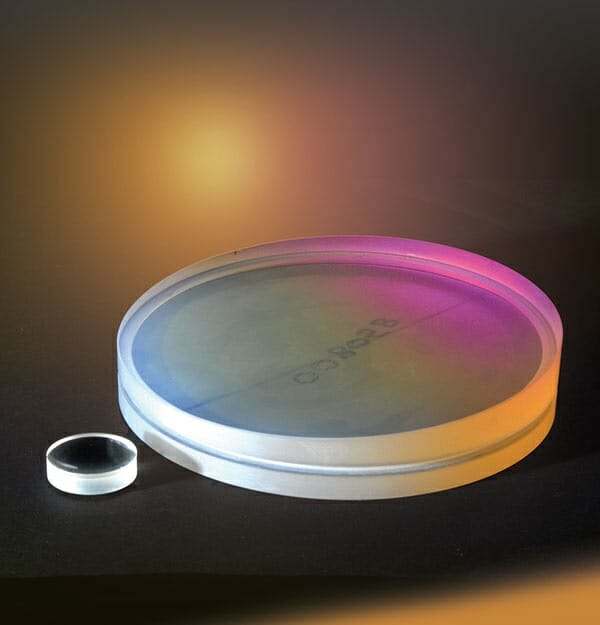

Dr Aris Kouris, Sales Director at Optical Surfaces Ltd. commented “We are very pleased to be involved in part of this important project to speed the development of new vector control products in the fight against malaria. We advised the Optical Engineering Group that they required an off-axis parabolic profile as it generates a collimated beam without obstruction of the optical path. The critical performance parameters for this application are the off-axis optical design, wide aperture and a good surface finish (< lambda/6) in order to produce a uniform phase-profile in the collimated beam. We look forward to seeing the results of this interesting research project”.

The work of the Optical Engineering Group at the University of Warwick School of Engineering is centred on performing basic and applied research in optical sensing technologies with applications across engineering, industry, the biological sciences and clinical practice. This research is frequently multi-disciplinary with active collaborations across these fields. For further information contact [email protected].

Optical Surfaces Ltd. has been producing optical components and systems for leading academic and industrial research groups for more than 50 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.

For further information on high precision off-axis parabolic mirrors please visit https://www.optisurf.com/index.php/products/off-axis-paraboloids/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / [email protected].