Aluminium is a material with many advantages. It combines lightness and mechanical strength. In addition to its corrosion resistance, it is also an excellent thermal and electrical conductor. Capable of being 100% recycled, the use of aluminium is constantly increasing in industry.

A material used in many sectors of activity

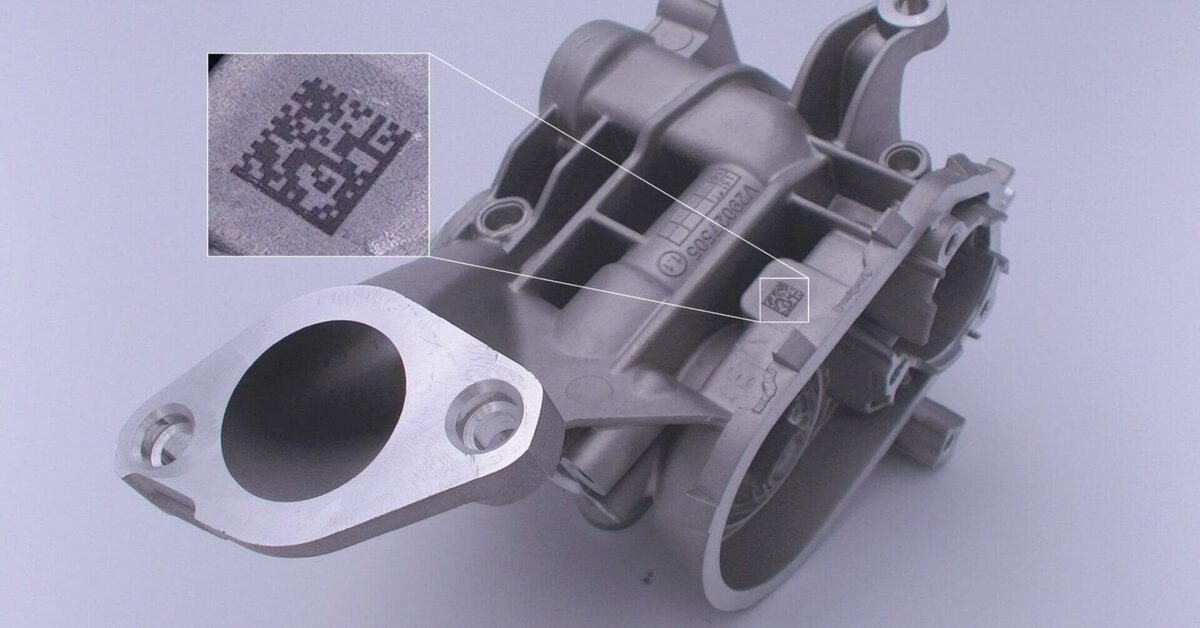

Aluminium is used in a very large sector of activity, particularly in aeronautics and shipbuilding, electrical and electronics industry and rail transport. It is also particularly appreciated in the automotive industry. In fact, many car manufacturers and equipment suppliers opt for this versatile material for the manufacture of car chassis, steering columns and power steering components. It is also found in the manufacture of turbo bodies, engine crankcases, cooler or automatic air conditioning elements. Aluminium also plays an important role in the fast-developing field of NEV (New Energy Vehicles), particularly in the manufacture of electric battery casings and other electronic components.

Various marking requests

As the use of aluminium is so varied, so are the traceability requirements. Indeed, the marking requirements are of a very different nature and require barcode, Datamatrix, alphanumeric or logo marking. In addition, there are several constraints linked to the nature of the aluminium (anodised, alloy, etc.) but also to the customer’s requirements, particularly in terms of marking contrast or depth. It is not uncommon to be asked for a marking capable of being visible after the application of any coating or of resisting various surface treatments such as shot-peening for example.

Perfectly adapted products from SIC MARKING

SIC MARKING, the world leader in industrial traceability, has been committed for over 30 years to providing the most appropriate marking solutions to meet the challenges associated with the identification of aluminium components. Its experience has enabled the French group to offer a technically superior range of scribing, dotpeen and laser marking machines, as well as a large number of automatic reading solutions for Datamatrix.

The SIC MARKING laser product range is particularly suitable for marking aluminium components both in series and individually. It consists of lasers that can be integrated with various options:

– 3D function for marking on complex shaped parts

– Vision function for fast and reliable barcodes and Datamatrix reading

– Rotary axis for cylindrical parts marking

The range is completed by 3 stations (L-BOX, XL-BOX and XXL-BOX) allowing to have a dedicated marking station. This can be integrated into a production line, or used as a stand-alone marking station. Small, medium and even large production runs are possible. The resizing of the boxes, the creation of specific tooling, the addition of additional movements (Z axis, rotary axis) are options available on request.

Many years of solid experience

The SIC MARKING lasers, which are favoured by many customers, are a great success with ETIs and large companies that need to mark their aluminium components. For this reason, the international group with 300 employees has had the opportunity to prove all the qualities of its solutions by taking up the challenges offered by major automotive equipment manufacturers.

Among these challenges was a particularly complex request from a major Japanese player in the automotive sector who wanted a station dedicated to marking Datamatrix codes on power steering components. The solution had to withstand a constraining environment (humidity, dust), fit into a small space and adapt to different part numbers. Based on its many years of experience, SIC MARKING was able to offer a compact customised station equipped with an HD laser automatically controlled on 2 axes, for fast and high-contrast marking. It is protected by a dust and moisture protection system, making it easy to integrate into a difficult industrial environment.

SIC MARKING was also recently used to provide a major German equipment manufacturer with the most suitable solution for its requirements. The customer wanted to mark a 7 x 7mm DMC code on air conditioning compressor pistons to facilitate their internal traceability. These codes needed to be marked deep enough to allow proofreading even after shot peening and tinning. All this in reduced cycle times. After various marking tests carried out by our dedicated project experts, the chosen solution was a 50W fibre laser, its power enabling it to carry out deep marking in record time.

SIC MARKING also includes markings on NEV battery components, turbo bodies, identification plates for electric motors, engine cylinders…

In addition to providing marking solutions that perfectly meet customer needs, SIC MARKING offers personalised support and a reactive after-sales service.