As with most disruptions, the pandemic has amplified the focus on productivity and forced injection moulding decision makers to reconsider how automation and digitalised technologies can facilitate working smarter.

Nigel Flowers, UK Managing Director of Sumitomo (SHI) Demag explores the impact the pandemic has had on injection moulding investments, including robotics. He emphasises that rather than a complete pivot, automation was already quite commonplace; especially among moulders producing components for the medical, healthcare, aerospace, automotive, electronics and packaging sectors.

Productivity is the challenge of our time. The World Economic Forum forecasts that half of all work tasks will be handled by machines by 2025[i]. Prompting moulders and OEMS to rapidly extend their continuous improvement programs. As well as investing in high performance and energy efficient machines, productivity, waste reduction and cost savings are critical focus areas.

Robotics with a range of motions

Some moulding robotic installations can be elaborate and complex. Others simple yet highly effective. Value is always the most important consideration. Any automation solution needs to solve the specific challenge, be scalable and offer a good return on investment. Often this is through increased output, enhanced quality, repeatable precision and reduced waste.

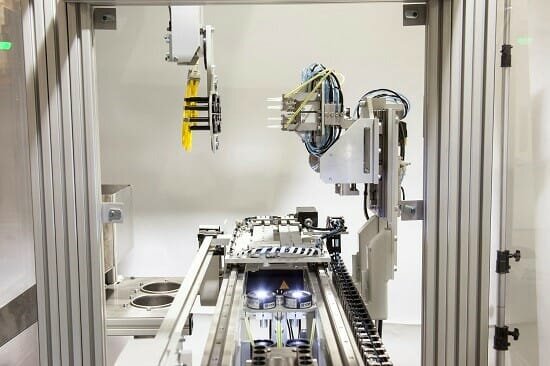

In high-care precision moulding applications, robots are usually chosen for their range of operation, accuracy, repeatability and cleanliness. Sometimes the customer needs to transfer parts, insert loads, apply labels or remove complex parts in non-linear movements. For hygiene sensitive markets in particular, the level of automation can be especially complex. The recent installation at the Injection Moulding & Extrusion Pilot Plant of BASF in Ludwigshafen, Germany is a good example.

Here, for operative safety and efficiency, a linear SDR 5-35S robot serves two purposes, selecting and placing one of 12 interchangeable mould inserts from a magazine located within the cell. After the part is moulded on a new Sumitomo (SHI) Demag IntElect 100 injection moulding machine, the same robot, fitted with a multifunctional gripper, gently extracts the test specimen from the mould. This is then passed to the small six-axis articulated-arm Yaskawa GP8 robot for precise cut of the specimens from the gate using a servo spindle drive punching machine.

Conversely, in many packaging and mass manufacturing environments, robotics is primarily used to make customer applications run faster and more cost-effectively. With take-out times of 0.5 seconds or less, it can sometimes be quicker to use a robot to remove parts than to let them fall under gravity.

At Essentra Components, integrating a servo drive robotic system onto their new 50-ton IntElect installed in early 2020 has eliminated the labour-intensive task of manually sorting and separating sprues. This simple automation configuration funnels parts where they need to go and removes waste plastic on ejection. It immediately resulted in a significant increase in yield. In a lot size of quarter of a million, one trial reported just 26 lost parts.

Call the diagnostics doctor

Notably remote machine monitoring has been the hallmark of 2020. The ability to take live data from moulding machines and use this to inform operational decisions and make process improvements has induced greater trust and a change in mindset about remote access tools claim experts.

From subscription remote diagnostic services to more viable innovations which doesn’t encroach on a company’s IT architecture and security firewall, manufacturers seek faster, slicker and more responsive remote troubleshooting solutions to improve operational efficiency summarises The Manufacturer and IBM in its recently published 2021 Digital Transformation Assessment report.[ii]

In the last 12 months, Sumitomo (SHI) Demag’s UK technical team – many also working remotely – resolved close to 400 individual issues and assisted 35 different moulding customers to maintain business continuity via its encrypted cellular 4G activeConnect tool. “Throughout this unpredictable trading environment, remote diagnostics has been a golden ticket to maintain operational efficiency and save money, while adhering to health and safety guidance and ensuring machine assets are safeguarded,” notes Nigel.

For a mass manufacturer of precision components, keeping the factory doors open and machinery fully operational has been critical to maintaining critical supply chains, note the authors of the 2021 Digital Transformation Assessment report. A full year since the pandemic shook our economy, improving operational efficiency is the most significant imperative cited by 92% of manufacturing leaders participating in the report. Participants also say automating various production processes, eliminating inefficient tasks and accelerating the implementation of ERP systems are critical focus areas. In terms of tech adoption, more than 75% have already rolled out robotics and automation.

Nigel adds: “In the next five years as businesses begin the recovery process, I foresee another leap forward in digitisation programs. Profitable organisations that might previously have struggled to secure roll out budgets will likely find that the 130% Super Deduction capital allowance will accelerate investments in moulding machines, robotics and tools.”

[i] https://www.weforum.org/reports/the-future-of-jobs-report-2020

[ii] https://www.themanufacturer.com/articles/two-in-three-manufacturers-say-covid-19-has-accelerated-their-digital-transformation/