High productivity and high quality with maximised utilisation of machines and cutting tools are everyone’s goals for CNC machining. Tebis release version 4.1 moves one step further for achieving these goals with additional functions for optimisation of CNC machining process. Added to Tebis CAD/CAM Intelligent Manufacturing offerings of manufacturing database libraries, Tebis V4.1 has been extended to include a new clamping device library, intelligent collision avoidance strategies, in-process measurement cycles and seamless integration of Tebis ProLeiS MES system.

Clamping device library completes the virtual process digital twins libraries

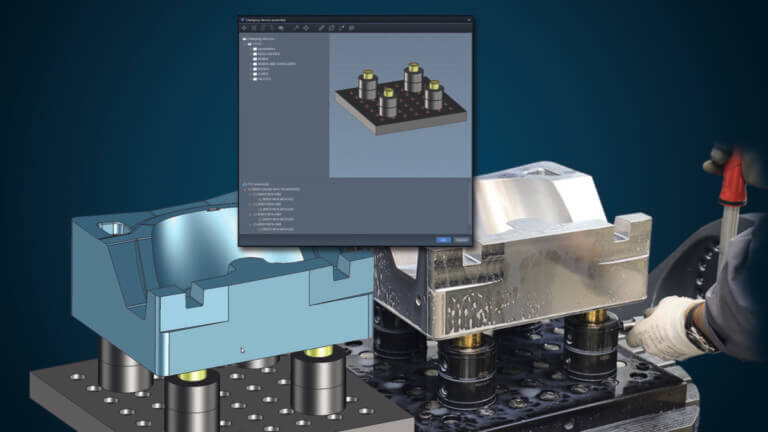

The proven manufacturing database libraries, in which all of the manufacturing components and experience data are stored, have been supplemented with a new clamping device library in the form of digital twins. This can be used to conveniently create and manage clamping elements and clamping device groups and to set up the machine in the virtual environment.

The new Tebis clamping device library also represents all common devices for fixing parts in the machining process. From the screwless vise to clamps and chucks, all common clamping devices can now be easily managed in a library and quickly used for realistic simulation and collision checking. In the CAD/CAM model, the precise clamping position can be exactly aligned, zero point and conventional clamping systems represented, and all assembly possibilities checked.

Virtual machine setup

The setup process follows logic similar to the assembly of clamping device groups: only clamping devices that fit on the selected machine are offered. It can also create the reference point when clamping. With just a few clicks, you can use connection points to position the clamping devices on the part and position the entire part on the machine table. The part, collision elements, clamping device groups and individual clamping elements can also be positioned independently.

The unique advantage: the result arrives at the setup station with no loss of information – because the NC output automatically generates precise and comprehensive NC documentation. The person responsible for the setup can immediately see what needs to be done. Clear component designations show the clamping devices required, how many are needed and where they have to be positioned.

Shorter setup and machining times with in-process measurement cycles

Completely integrate your measuring tasks in the manufacturing process with NC programs – easily and with reliable collision protection. The CAM programmer can simultaneously check to ensure that the part is correctly set up and that the blank is correctly dimensioned and oriented. All of this can be monitored automatically. This again prevents unnecessary downtime and even tool breakage or machine damage.

All of the necessary functions are structured together – from probe calibration to point measurement, angle measurement based on points or circles, circle and rectangle measurement, to checking of grooves and ribs. Integrated tolerance testing can be performed to determine whether the order can continue to be machined or must be interrupted. This results in a reliable and highly automated process with combined milling, turning and measurement operations that prevent damage to tools and machines. This results in shorter setup and machining times, higher component quality and fewer correction grinding operations.

Tebis ProLeiS MES software fully integrated

Large savings can potentially be realised in single-part manufacturing, thanks to optimised and stored manufacturing processes.

With ProLeiS and Tebis 4.1, you can split up entire assemblies and individual parts into proven processing sequences. Even complex manufacturing projects can be planned, controlled and implemented. Logistics for purchased parts, blanks and machine components are also accounted for throughout the process. The key advantage: your machines are optimally utilised and all activities can be assigned to specific manufacturing designers, NC programmers and machine operators.

ProLeiS MES can also be easily combined as an integration platform with upstream and downstream systems like PDM, ERP and machine control systems.