The year 2020 has been completely out of the ordinary and it has taken each and every one of us by surprise. From the level of individuals to that of local communities and multinational corporations, the Covid-19 pandemic has changed the way we work, travel and relate to each other. This has also led to many businesses changing their traditional processes to the online environment, digitise their data and remove bottlenecks in the “new normal” working world.

One company that is ahead of the curve from this perspective is process automation and industrial control system integrator InControl Systems. This Chesterfield-based company has been providing turnkey solutions for process control, automation and information systems for over 20 years. From consultation and conception through to design, implementation, commissioning and the provision of comprehensive support packages, InControl strives to help its customers increase their efficiency and productivity.

“We knew of EPLAN packages as their reputation precedes them”, explained Ian Clarke, of InControl Systems. “And, due to the high calibre of major end-users and OEM clients we work with, we wanted to improve our offering and put better and more effective processes in place. Having accurate and dependable documentation at the touch of a button is now a standard requirement for many industry sectors, and we are confident EPLAN will help us to deliver this.”

With these considerations in mind, InControl purchased two EPLAN Electric P8 and two EPLAN Pro Panel licences. A further benefit was that, although InControl is not a panel builder, this software would allow its engineering team to provide panel layout instructions for their approved contract panel builders and thus optimise the building process.

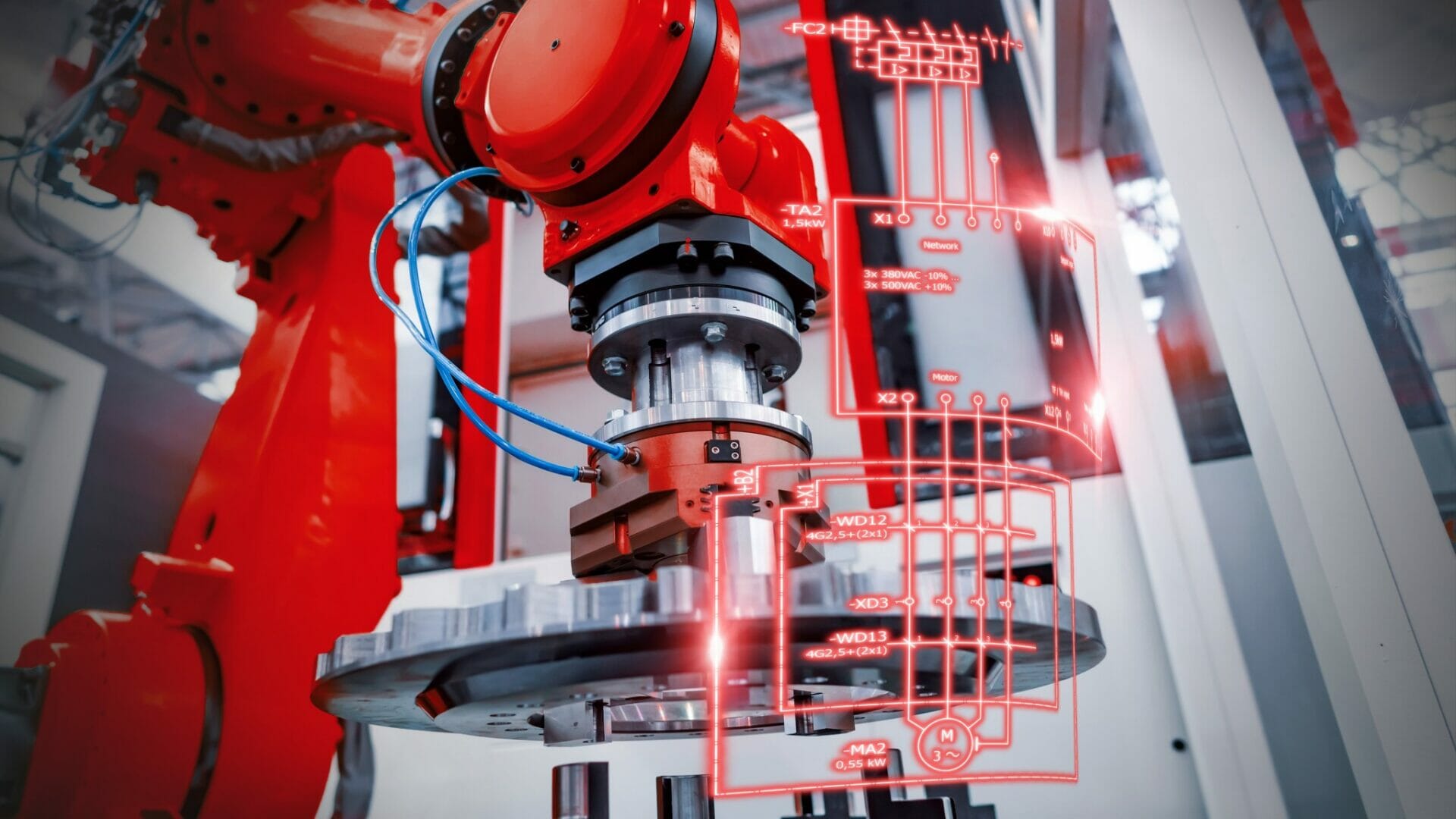

EPLAN Electric P8 is an electrical engineering design software package that offers a comprehensive range of facilities for planning, documentation and management of automation projects. Among its many key benefits is support for reusing design elements, which means that once developed, the same elements can be included in multiple projects. This not only saves time but ensures consistency and minimises the risk of errors.

Also automated by EPLAN Electric P8 is the production of documentation, which means that all those working on a project, whether they are involved with production, assembly, commissioning, testing or subsequent day-to-day operation, always have access to detailed and accurate information.

“On larger projects, EPLAN Electric P8 brings us the benefits of automatic generation of BOMs and cable schedules”, said Jan Hemper, Technical Director at InControl Systems. “Using EPLAN Electric P8 and EPLAN Pro Panel provides us with all the tools we need to create intelligent configuration-based electrical designs. It also guarantees tighter design controls and modular standardisation, which are useful when we need to use different panel builders for different elements of our projects.”

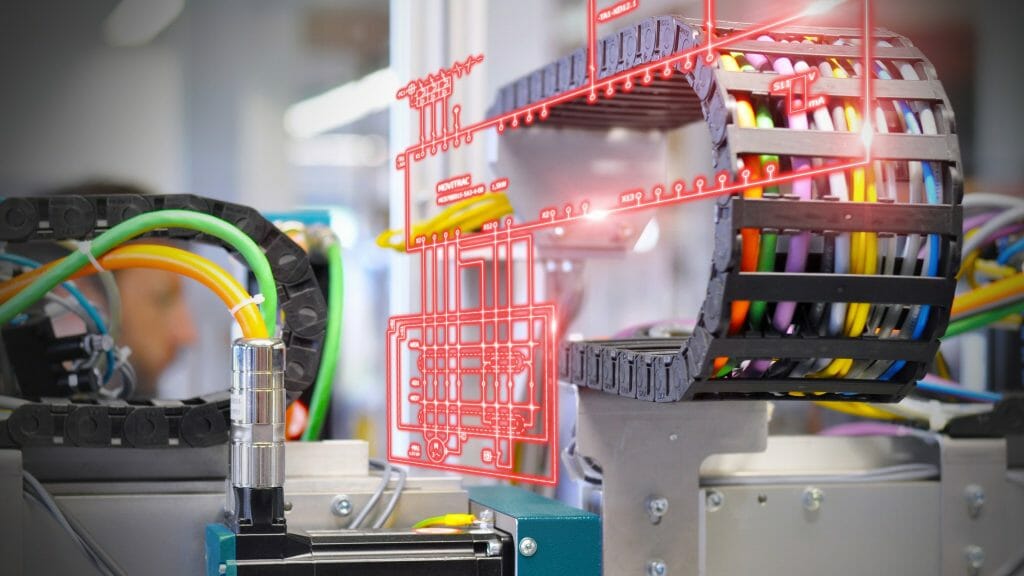

EPLAN Pro Panel works in conjunction with EPLAN Electric P8 to greatly simplify the design of control panels. It has been developed with flexibility in mind and enables users to follow their own preferred design approach, whether it is based on equipment lists, connection lists or circuit diagrams. All necessary components can be easily entered and positioned on the 3D layout.

As an added benefit, error detection and other aspects of consistent quality control are implemented at the development stage. Features such as collision control ensure the panel is built right first time, making testing much easier and virtually eliminating the need for reworking.

To learn how to make the most of the packages they had purchased, InControl engineers attended two separate training courses. As these took place at the height of the Covid-19 pandemic, they took the form of high-quality remote virtual training. This meant that all those participating could enjoy full involvement, but from the comfort and safety of their own home-offices.

The concept of virtual classrooms is becoming increasingly popular, as it allows people to attend from anywhere in the world. As EPLAN continues to focus on digital service offerings to ensure that customers can use their services as best fits their needs, virtual training courses are now a permanent fixture. To ensure that the same one-to-one dialogue is provided online a limit of 6 per training course has been put into place.

InControl also makes extensive use of the EPLAN Data Portal, a cloud-based resource that provides access to detailed component data on hundreds of thousands of electrical, mechanical, fluidic and pneumatic components. With its new user interface, an intuitive search and smart suggestion function, the portal is now easier, faster and more efficient than ever. The enhanced search function offers fast and practical support, whilst the suggestion function (for product groups, components or manufacturers) is exceptionally easy to use as its “look and feel” is similar to that of popular search engines.

Updates can be imported at any time – whether in the application itself or in the portfolio of data from more than three hundred component manufacturers. Between them, manufacturers offer data on more than one million devices for direct download. This ensures that engineers who use the Portal can always be sure that they are working with the latest and most dependable data.

As for InControl, the company continues to be a leading light in digital transformation projects within the industrial manufacturing and process industry sectors. “Utilising EPLAN’s CAE tools, support and training, enhances our professional services capabilities within Industry 4.0 applications. We are seeing more and more Smart Factory projects in sectors such as food & beverage, aggregates, oil & gas, metals, paper and many other markets. But we are also seeing more requirements with OEM machine builders, who are demanding the levels of documentation and design, that EPLAN helps us deliver and this bolsters our growth plans” concludes Ian Clarke.

“It’s great to see companies like InControl investing into automation technologies at a time of uncertainty,” said Ken Christie, Director at EPLAN UK. “By investing in these uncertain times, engineering compabies can add value to their customers. We believe that now it is the right time to enable new growth and create efficiencies across the board.”