Although air is considered by most to be a free commodity, the reality is when air is being compressed to support manufacturing processes, it can be an inefficient and expensive process.

Automation specialist Brillopak examines the sustainability challenges of compressed air and the steps it has taken to address this issue on its UniPAKer robotic crate packing series.

The sustainability of compressed air as an industrial power source is a bit of an oxymoron. Air itself is clean, safe, convenient and abundantly available. However, the environmental impact of poorly maintained compressed air systems has been long debated.

Reviewing a facility’s compressed air system will undoubtedly reveal many opportunities for reducing energy consumption. All of which can result in considerable savings, improved operating costs, without large capital expenditures.

Used to operate equipment such as pneumatic controls, air tools, pumps, valve actuators, robotics, pistons and larger-scale processes, compressed air typically accounts for up to 40 percent of a manufacturing facility’s total energy bill. Additionally, leak rates can exceed 50% on some compressed air systems.

As well as being a direct source of wasted energy, these leaks can cause major pressure system drops affecting output. This in turn makes the compressor work even harder, shortening the equipment’s lifespan and causing excessive equipment wear and tear.

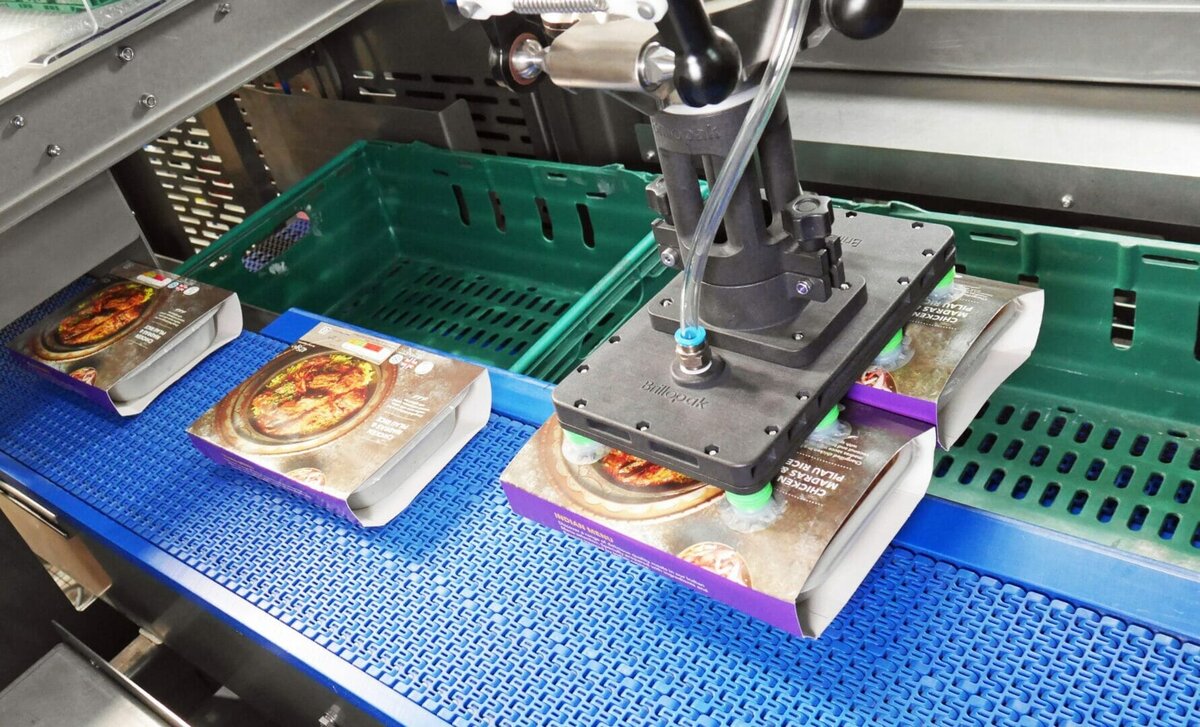

Taking the lead to reduce automation carbon emissions and meet the UK’s new 2050 Net Zero targets, Brillopak has re-engineered its UniPAKer’s compressed air pressure system and end-effector vacuum generators.

Working collaboratively with the cartridge manufacturer, Brillopak has successfully built the vacuum generators into the end-effector head. Now, rather than sitting external to the end-effector, air is drawn into the centre of the head and fed to each of the five generators, all of which are contained within a special internal casing. Delivering more consistent, targeted and faster airflow.

Tested against early-generation end-effectors, Brillopak reports a 45 percent reduction in air use when picking up and moving products of the same weight into retail crates. Brillopak Director Peter Newman explains. “When we examined the volume and flow rate data on the UniPAKer equipped with these new end effectors, we measured the compressed air system operating at a much lower stable pressure in shorter quicker bursts.”

Creating sustainable value across the entire packing cycle, by adopting this ‘whole system air flow approach’ and improved control and distribution of air, Brillopak reports a 10% reduction in power usage compared to previous models in the series.

Targeting climate neutral

Servo drives are proven to be extremely efficient relative to power use in automated cells. By carefully controlling all aspects of the work envelope, the acceleration and deceleration of the robotic arm is better controlled. Striking the optimum balance of fast acceleration and gentle pick and placement, the movement of the UniPAKer’s arm is fluid. “There’s no wasted time. As an electrically-powered robot, energy is only used when the robot is in motion,”explains Peter.

To help manufacturers meet the UK’s new 2050 Net Zero targets, Brillopak has expended a lot of energy re-examining all potential resource-intensive tasks, including the efficiency of every process and component to ensure power is not being wasted. For example, integrating Brillopak cells with electronics up the line helps to pre-empt bottlenecks, address production lags and respond instantly. If no products are coming off the bagging machines down the line, idle conveyors stop.

Sustainability is a never ending cycle of improvements, notes the self-professed eco-engineer. “At Brillopak, every action makes a difference. We have a duty to examine all direct and indirect emissions. Applying the concept of the circular economy that everything has a value, we always use tried and tested energy-efficient components in every build,”says Peter.

Conveyors used in Brillopak cells, for example, are sourced from a company that only include motors, inverters and mechatronic drives with optimised energy efficiency. Likewise, the company optimises the payload/arm weight ratio to maximise efficiency. Automating tasks like case loading and palletising has long been presented as a solution to boost productivity and efficiency and address labour shortages.

The same pressure is on for compressed air systems. As an integral part of the manufacturing process they are unlikely to disappear any time soon. Yet, as Brillopak has uncovered, there are more sustainable options to reduce the psi which in turn reduces energy consumption.