Through its exclusive UK and Ireland distribution partnership with Burster GmbH, Ixthus Instrumentation Ltd supplies complete solutions for manual presses where the German measurement specialists’ load cells, displacement sensors and monitoring electronics can realise consistent production quality and throughput improvements as well as overall TCO savings and potential for preventative maintenance. Available as system integrated components retrofitted to customer’s existing manual presses or supplied as complete force- and displacement-equipped hand lever press machines like Burster’s 5501 model With a wide choice of monitoring and process analysis offered, these solutions equally suit small- to medium-batch parts production for press forming, stamping, gear and bearing component assembly, powder compression, and more where 100 % monitoring and documented operation ensures enhanced certainty.

Specially designed for measuring the steep forces that occur in hand operated presses as well as automated presses, Burster’s 8552 and 8451 series load cells measure the compression forces between the circular contact surfaces of plunger and tool. With an overall height of less than 50 mm the compact and robust load cells provide measurement ranges from 0 to 100 N and up to 0 to 100 kN. With simple mounting on the press-ram the load cells suit stamp borings of 10 to 20 mm with H7 tolerancing. Within each product series a wide choice of load measurement ranges are available with load pins and hole diameter interchangeability a key feature for flexibility and easy product changeover. The standard model 8552 suits most manual presses up to 25kN and includes mechanical overload protection.

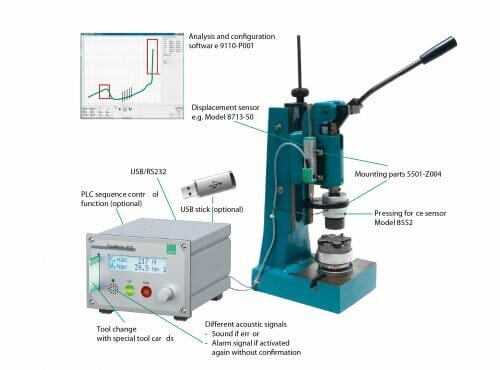

Image – clockwise from top left: Burster’s 8451 & 8552 force sensors, 8712 & 8713 displacement sensors, DigiForce 9307® , DigiForce 9311® and ForceMaster 9110 force monitoring hardware – available with system integration for press retrofit from Ixthus Instrumentation

For press and similar load measurement applications where a displacement sensor is required, various options are available with linear measurement ranges from 0 to 10 mm up to 0 to 150 mm. Offering long-life, high durability and precision, these potentiometric sensors provide full scale non-linearity specifications of up to 0.05 % and a typical resolution of 0.01 mm. The rods are guided in long-life, low friction sliding bearings with a stainless-steel ball-type probe tip. Optional probe tip followers, spring return mechanisms and a comprehensive selection of mounting accessories make installation straightforward.

There are three options for measurement electronics that provide varying levels of performance and cost from the ‘Plug and Work’ ForceMaster 9110 series to the intermediate DigiForce® 9311 and the comprehensively equipped DigiForce® 9307.

For many press and stamping tasks the ForceMaster 9110 2-channel force/displacement controller will provide excellent value. In its basic configuration, force/time data is monitored and with an optional linear displacement sensor force/time/displacement can be added for stroke monitoring. Auto-configuration with sensor recognition via a smart card system named ‘Card & Go’ makes set-up straightforward with the load cell data transferred to the unit to allow even small production runs to be quickly and conveniently arranged. This basic control unit features a two-line LCD display for force and displacement with OK and NOK indicator lights. An integrated acoustic signalling device also indicates pass or fail with the ability to change tone and volume allowing several 9100’s to be located close together in a production shop. The unit also includes a USB/RS232 interface and free of charge configuration, parameterisation and evaluation software to allow set-up and monitoring of the press though a PC. A USB memory card can also be used for storing and transferring data as well assisting evaluation and documentation by a remote PC. The 9110 ForceMaster also features a PLC sequence control function that can be used for automated tasks such as pneumatic workpiece clamping, automatic parts removal etc.

The mid-range 2-channel DigiForce 9311 adds PROFIBUS, PROFINET and EtherNet/IP connectivity to press operation and monitoring. With Burster’s TEDS automatic sensor recognition and a 3.5″ colour touchscreen display, up to 16 programs may be stored and retrieved. User configurable IO can be used to assist automated press functions as well as alarms. The force/displacement controller can handle all worker, admin and identification data and may used to evaluate forward and return stroke curves. With live sensor values sent to the fieldbus interface, synchronous logging of measurement data using Burster’s DigiControl PC software allows complete certainty and documentation records for multichannel press applications.

Bursters DigiForce 9307 is aimed at high-end press machine applications where other processes require control and monitoring. The comprehensively equipped unit can offer advanced features for the most exacting manual press applications where necessary. With all the features of the 9311, the 9307 adds an EtherCAT fieldbus and a PLC interface for up to 6 measurement channels with 0.05% measurement accuracy at a high-speed 10 kHz measurement rate. Up to 128 measurement programs may be stored and a large 5.7“ LCD colour graphic display provides visualisation for measurement curve and computed evaluation results whilst a numerical keyboard offers straightforward parameter and parts entry. The 9307 also features maths functions, independent and variable start/stop logic and its suitability for process monitoring extends to applications such as joining, riveting, caulking, checking torque curves and more.

Ixthus instrumentation Ltd provides comprehensive technical sales and support service for Burster’s complete range of measurement solutions from component level or for complete instrumentation systems.