When you need the accuracy but don’t have the room or the budget.

UK Robotics has recently launched a new liquid handler to shake up the lab automation market. Feedback from small biotech companies and big pharmaceuticals has been beyond the company’s wildest expectations.

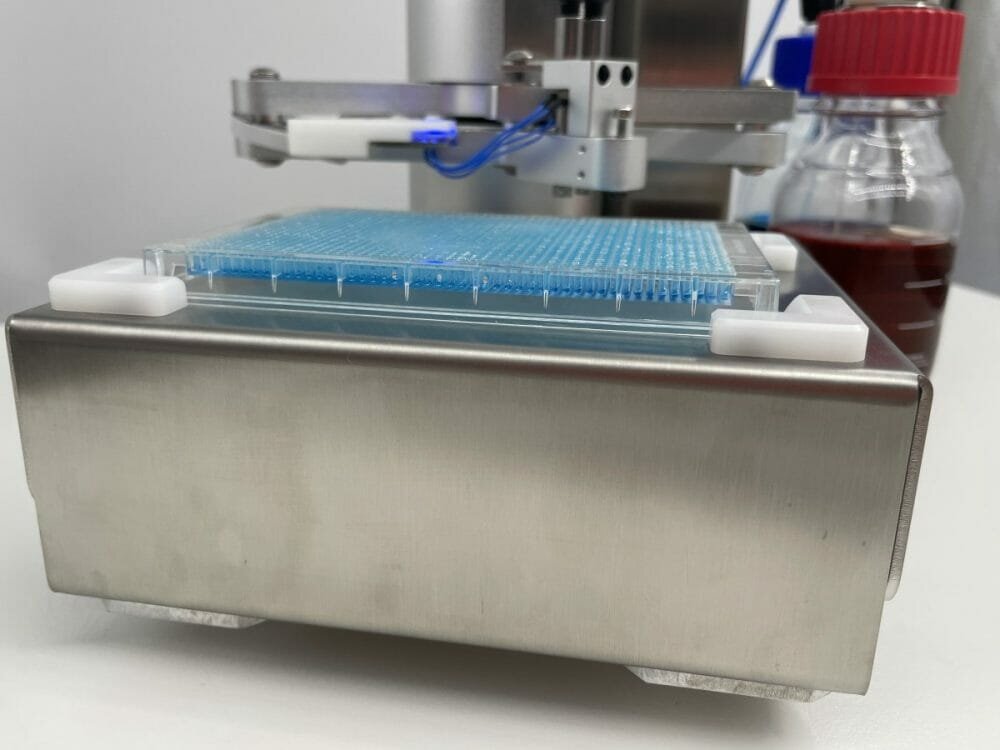

The Bolton based company specialises in building integrated systems for lab automation for life sciences. They have now used their 15 years of experience in the industry to create a new two valve nanolitre microplate reagent dispenser.

Most life sciences experiments run in biotech and pharmaceutical companies start with a microplate, a flat plastic plate with small holes (wells) used as test tubes. A 120mm x 80mm microplate will have 1536 wells; this is used to run thousands of experiments using the same volume. Before lab automation, pipettes were used to move liquids by hand into large tubes; large tubes required large volumes of liquids, which meant the number of experiments was limited. It is essential that the dispensing and fluid volume control are extremely accurate before the experiment.

Miniaturisation has existed for a while but usually at a price. The UK Robotics liquid handler, the d2, is small; it is 25% smaller than other dispensers and has a lower price point. These factors are hugely important for start-ups or companies with limited lab space and budgets who still need to maintain accuracy.

The d2 uses two maxon brushless EC 60 flat motors for the arms for the X and Y coordinates. The Z-axis uses the maxon EC 45 flat with a mile encoder. The motors needed to provide consistency, accuracy, and a smooth torque curve. The sample is delivered through a hole of just 0.1mm through a dispensing head valve made of polished sapphire and ruby, which is robust enough to allow for cleaning and sterilisation without damage. The machine can accurately deliver 40 samples per second.

Mike Counsell, UK Robotics founder, said ‘I know there are lots of cheaper motor manufacturers, but we needed the consistency that maxon is known for. The accuracy of our product is paramount.’ when you calibrate for one motor you know it will be the right calibration for the others; you don’t want to be calibrating each one every time.’

Please get in touch with the maxon media office for more information: [email protected] +44 01189 7333378