Post-assembly magnetisation of permanent magnet rotors is the most cost effective and accurate way to produce these vital components for electric vehicle motors. Bunting is promoting such post-assembly magnetising manufacturing techniques on stand C4-607 at the Cenex LCV Event (7-8 September, UTAC, Millbrook, UK).

Bunting is one of the world’s leading designers and manufacturers of magnets, magnet assemblies and magnetising equipment. The Bunting European engineering and manufacturing facilities are in Berkhamsted and Redditch, both in the United Kingdom.

The Cenex LCV Event focuses on low carbon and fuel cell technologies and includes a technology exhibition split over three halls, and a comprehensive seminar programme.

Electric vehicles have a heavy reliance on magnets and magnet assemblies as their main traction drive, replacing the Internal Combustion Engine (ICE). Minimizing the assembly cost directly correlates with the capability of the UK to maintain its position as a leader in vehicle propulsion production.

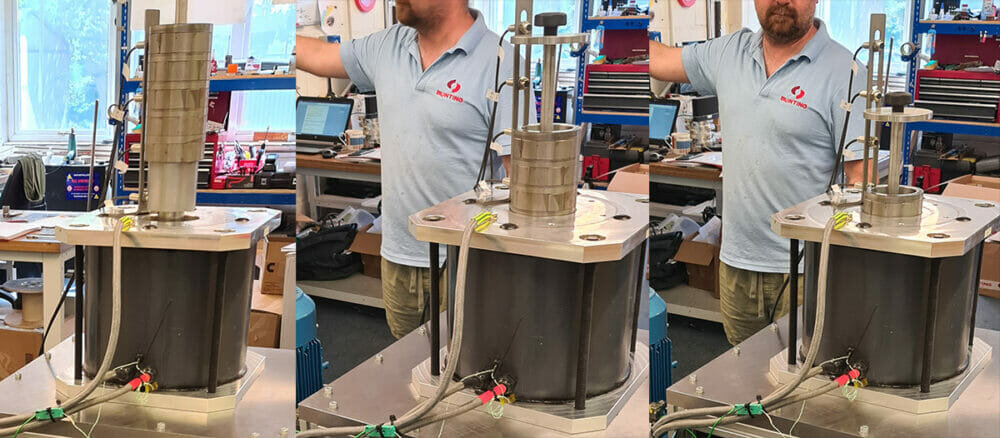

Assembling a magnetised high-strength neodymium magnet assembly is risky to the operator and the magnets due to the twisting and awkward magnetic forces involved. To enable post assembly magnetization, the design needs to consider a Halbach array or an Internal Permanent Magnet Rotor (IPM) design. Bunting’s engineering team work together with the customer to develop the design for the inert magnet assembly that can be safely, repeatability and easily-built, without tooling and with Poke-Yoke techniques. The system is then safely magnetised constructed and this technique greatly simplifies and reduces the cost of the whole manufacturing process.

There are many advantages to post-assembly magnetisation. Constructing the magnet assembly is easier and the time taken is shorter. There is also a reduced risk of mistakes occurring during assembly (e.g. incorrect polarity orientation). Post-magnetisation also ensures that the polarity and magnetic field are consistent for every magnetic component, meeting the tight specifications of both the automotive and aerospace sectors.

“The repeatability and quality requirements of the automotive sector drive the continuous development of our post-assembly magnetization technology,” explained Matthew Swallow, Bunting’s Technical Products Manager. “The manufacturing techniques we develop enable the build of magnet assemblies without risk of error and with significant cost reduction.”

For further information, please contact us on press@buntingmagnetics.com or visit our website:

Bunting-Berkhamsted – www.bunting-berkhamsted.com