Leading micro molding specialist Accumold is pleased to announce that it will be exhibiting at the upcoming “Universe of Pre-Filled Syringes and Injection Devices” Conference, October 18-19, Palm Springs, CA, USA.

The 2022 Parenteral Drug Association conference will continue to build on the reputation of past events while bringing to light the latest advances in the field. The conference will explore the future of pharmaceutical devices — such as rapid technological advances — that will push the industry ahead while bringing together industry experts to share their experiences, new developments, regulatory considerations, challenges, and industry trends in this exciting area.

Aaron Johnson, VP of Marketing and Customer Strategy at Accumold says, “Continued advances in materials of construction, manufacturing processes, injection processes and safety devices, and other technology improvements create a dynamic environment in the drug delivery device arena. Regulatory requirements, industry experience, and evolving market trends are critical considerations to ensure a complete understanding of the application of pre-filled syringes or other pre-filled containers and injection devices to drug delivery. The challenges of new product introduction and support of existing products require that companies be aware of new developments.”

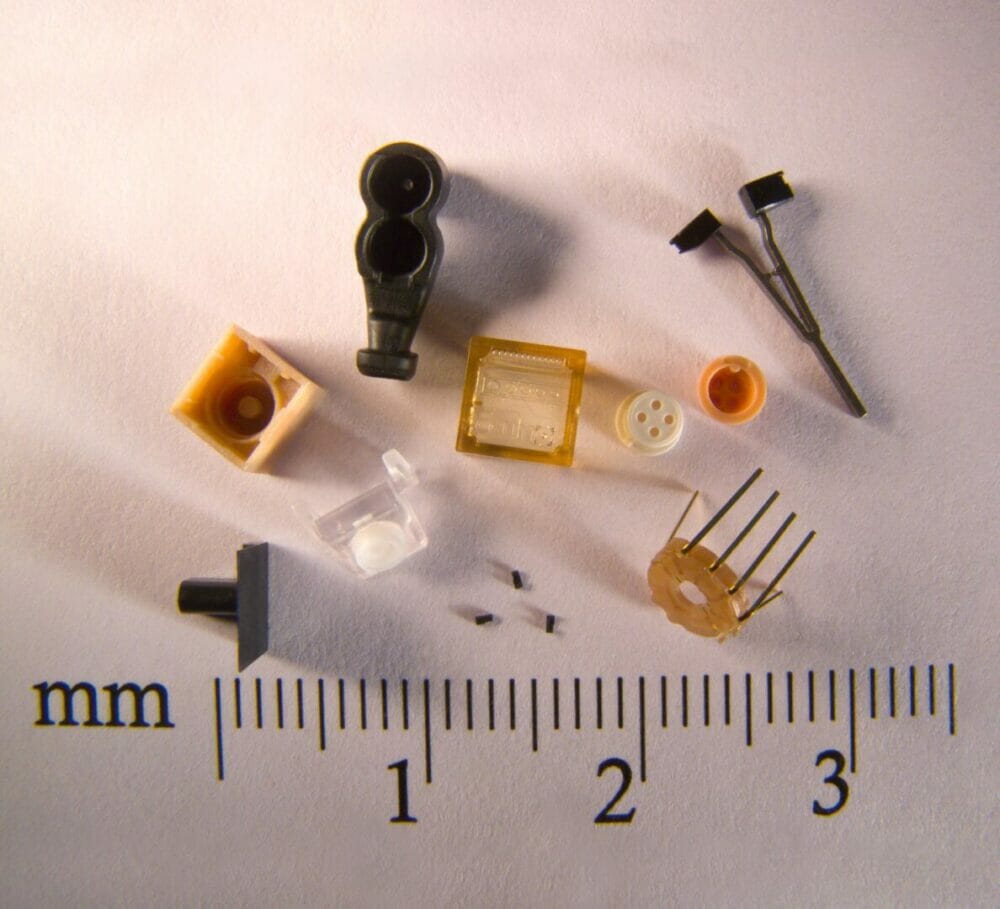

“Accumold continues to evolve the micro molding process to make ever more intricate plastic parts and components reliably and repeatably for a host of global medical device and drug delivery OEMs. We are looking forward to meeting the drug delivery community and explaining to them the way that we can work with them to realise their manufacturing endeavours. The success of Accumold is driven not just by its experience and expertise in micro molding, but also by the fact that it is a truly vertically integrated company. Vertical is vital for success. We work with companies that require absolute precision, zero failure rates, and often need to push the boundaries of what is perceived possible in terms of miniaturization, material use, and part complexity. To be able to produce extremely precise micro molded parts repeatably and to be able to scale up to mass high volume manufacturing requires that your chosen micro molding partner offers design and material assistance, micro tool fabrication, proprietary micro molding services, cutting-edge metrology, assembly, and automation. Accumold has all this under one roof, and this allows us to streamline our customers’ product development processes, and attain optimal outcomes in terms of timeliness, cost, and accuracy.”

For over 30 years, Accumold has been pioneering the industrial application of micro molding across various industry sectors that require affordable, timely, and miniaturized parts and components, while at the same time catering for the inexorable demand for more complex geometries, the use of an array of complex to process thermoplastics, and tighter and tighter tolerances.

Johnson concludes, “Exhibiting at the ‘Universe of Pre-Filled Syringes and Injection Devices’ Conference will be hugely important for us as we continue to work with OEMs to innovate ground-breaking products in the drug delivery space. To a certain extent, in the area of precision plastic part manufacturing, quality of outcomes should be a given, and so Accumold’s focus is on what we can offer our customers beyond the production of a quality part. By this we mean those elements of a product development process that our experience can be brought to bear to produce not just a good part, but a highly innovative part that gives competitive edge, best functionality, and ensures end-use efficacy at affordable prices and in a timely fashion. Add to this the fact that Accumold’s 130,000 square foot facilities allows the physical space to ramp up to mass production, and drug delivery OEMs have in us a trusted and highly experienced product development partner that can optimize manufacturing outcomes.”

The Accumold team invites all attendees at the PDA conference to visit its stand and discuss how the company can help with specific applications and projects.