Through the use of its in-house technology for template-based 3D microfabrication, Horizon Microtechnologies is opening up various application areas that have until now not been able to benefit from the agility, versatility, and innovation possible through the use of additive manufacturing (AM), more accurately micro-AM.

One such application area is in the production of parts and components that need to suppress electro-static discharge (ESD) and its potentially damaging effects. With modern electronic components becoming more and more sensitive to static discharge, antistatic protection requirements are broadening and toughening across the micro-electronics sector. Horizon’s break-though technology is positioned to significantly help in the elimination of ESD in applications that would benefit from 3D printing by combining precision polymer micro-AM and ESD compliancy.

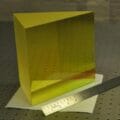

Template-based 3D microfabrication exploits the usefulness of polymer micro-AM produced 3D microstructures for hitherto unserved areas of industry by adding material and functionality to the microstructure, typically with a post-build coating process. As such, Horizon bridges the gap between polymer-based micro-AM and parts with enhanced functionality such as conductivity, heat-resistance, and other polymer-incompatible attributes.

Andreas Frölich, Founder and CEO of Horizon says, “At Horizon, we can make parts with a controllably conductive surface coating and can also coat internal channels with multiple bends. This allows us to make very compact and high-performance end-effectors for vacuum pick-and-place devices which are at the same time conductive enough to prevent electrostatic discharge. Antistatic properties and ESD safety also enables the use of our parts under conditions requiring spark-freedom and explosion-protection.”

ESD is the release of static electricity when a charged object comes into contact with a second object. This can be an expensive problem in many industrial environments, and is hard to avoid as it can arise from trivial processes such as two objects rubbing against each other, one becoming positively charged and one negatively charged. These charges can then easily flow or jump to different objects, even over short distances in open air, one example of this being the “shock” or spark that is sometimes experienced when touching a metal doorknob after walking across a carpeted floor. In everyday life this is just a nuisance, but the associated short but intense electrical current can easily be sufficient to cause permanent damage when flowing to or across electronic components in a manufacturing setup. In contrast to finished devices or products, the bare components are not typically protected against ESD, so the current may end up flowing through sensitive areas such as thin electrical tracks on a circuit board, generating enough heat to melt the track, or otherwise damage the component.

To overcome this, all materials and tools used in a production setting require a minimum amount of conductivity as well as proper grounding to allow a controlled release of any potentially present electrostatic charges. Additionally, the onus falls upon part and component designers to “design in” protection by making products and assemblies as robust as possible in resisting the effects of ESD. Either way, remedial actions have to be taken, can be expensive, and restrict design freedom when attempting to innovate new and better products and components. It goes without saying that as the circuitry within electronic devices continues to get faster, smaller, and more and more sophisticated the sensitivity to the effects of ESD are only likely to increase with time.

As an example of the use of micro-AM conductive parts in ESD prone areas, tooling for pick and place machines shows the usefulness of Horizon’s conductive coating technology. These machines are automated assembly machines for putting tiny electronic components such as chips, resistors, and capacitors onto printed circuit boards at the positions they are needed at a very high speed. The smallest standardized part sizes can be as small as 0.1 mm by 0.05 mm in such applications. Pick and place machines can also be used to position optical and electro-optical components such as bare laser diodes onto larger assemblies. In both instances, the components are very small, ESD sensitive, and will typically have at least two electrical contact points, each of which needs to be placed precisely with respect to whatever they are being placed on.

Frölich concludes, “This requires a precise tool such as an end-effector or pick-and-place-head to move them. One common way of moving these components is to have a head that has a small orifice (smaller than the component) connected to a vacuum line. This is brought close to the component, the vacuum is switched on, and the component is sucked to the orifice and sticks there until the vacuum is turned off. Especially with laser diodes, there may be “no-touch” areas on the component as well, imposing additional restrictions on the shape of the end-effector. The small features, required tolerances, almost arbitrary shape, and internal channels required can be achieved easily using micro-AM, and our coating process introduces the necessary conductivity to prevent ESD issues.”

Through the use of Horizon’s technology, electronics manufacturing services, developers of assembly and handling equipment as well as electronics packaging designers can now explore the use of polymer micro-AM without having to worry about ESD compliancy.