Applications of single use bioreactors are increasing driven by the biotech industry. At the same time, factors like market volatility and cost pressures are creating a need for faster process design. Here, Giuseppe Menin, Life Sciences & Process Industry Manager at COPA-DATA, explains why the zenon MTP studio software platform is essential for helping manufacturers in life sciences integrate modular technologies, like bioreactors.

Manufacturers are turning to modular production to speed-up processing. In a survey of 200 manufacturers in Germany conducted by PwC, 29 per cent said they were already using assets for modular production and a further 36 per cent said they would use the systems within the next five years. Going forward, modular production assets — like robots, storage vehicles and more — will increasingly replace large, fixed and inflexible production systems. This trend also applies to pharmaceuticals.

As written in Chemical Engineering and Processing – Process Intensification, Volume 159: “Increasing economic challenges like market volatility, product diversification and cost pressure lead to the need for faster process design.” In this instance, Faster process design means modules must be integrated into process lines quickly. That includes innovations for pharmaceutical manufacturing, like single use bioreactors.

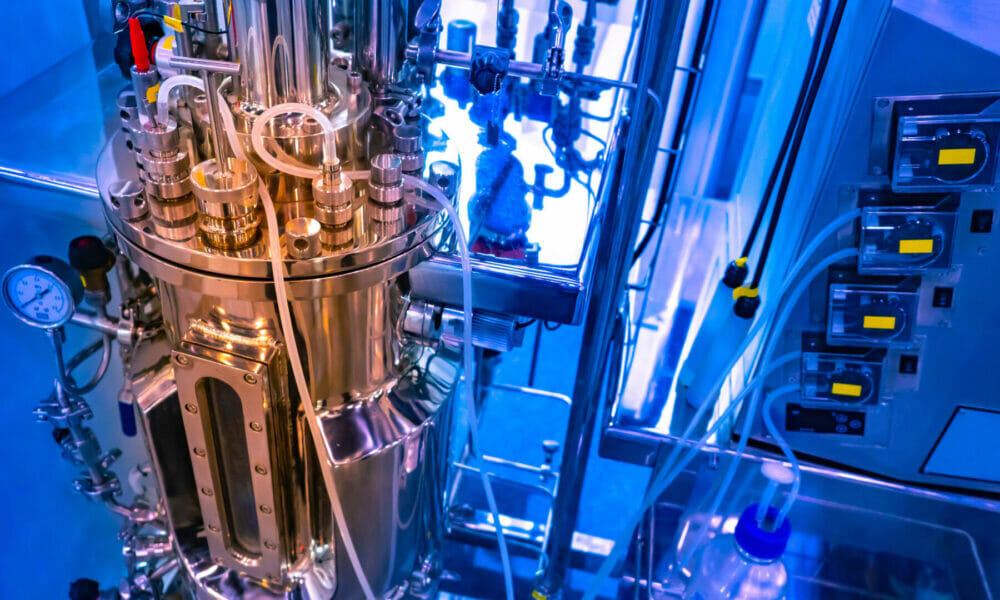

The American Pharmaceutical Review describes single-use systems (SUS) as bioprocessing equipment that’s designed to be used for a single manufacturing campaign, then discarded. SUS equipment is essentially plug-and-play, which makes it quicker to set-up new processing lines. Using SUS equipment also avoids weeks of cleaning, sterilization and validation that would otherwise be necessary when reusing conventional stainless steel equipment.

A single use bioreactor follows a similar principle and has a disposable bag, instead of a culture vessel, in which microorganisms, like human tissue, are grown. Forbes predicts our food could one day be grown in a bioreactor rather than on a farm. But, for now, their use is mainly for medical and bioprocessing applications.

The challenge for systems integrators is to connect and automate these modular bioreactor units seamlessly into pharmaceutical manufacturing processes. Crucially, this must be achieved while keeping-up with new and evolving integration standards in the heavily-regulated pharmaceutical industry. One answer to this challenge is plug-and-produce.

Quick connections

Plug-and-produce refers to the ability of a production system to automatically identify new or modified components, then integrate them correctly into production processes. Ideally, this would be achieved without any significant changes to the system.

Modular assets — sometimes referred to as Process Equipment Assemblies (PEAs) — are integral to plug-and-produce because each has its own local programmable logic controller (PLC), and an optional human machine interface (HMI). PEAs are pre-designed, so can be chosen and installed quickly rather than opting for inefficient tailor-made process designs. What’s more, this process is improved considerably by the Module Type Package (MTP) approach.

Each PEA in the plant is given its own digital identity, stored as an MTP file also known as a manifest. The file contains vital information on the PEA’s communication protocols, services, a HMI description and maintenance information. The MTP file allows quick and reliable connections between PEAs, so they can be controlled easily by the plant’s central Process Orchestration Layer (POL).

Let’s imagine an automation engineer wishes to design a bioreactor as a PEA. How would they go about achieving this?

First, the engineer must create a MTP file that describes the bioreactor’s important parameters — relating to dosing, mixing and heating, the HMI and more. Second, the engineer must match the MTP file to PLC logic commands. Third, they must generate OPC Unified Architecture (UA) variables, which is the cross-platform IEC62541-standard for data exchange from sensors to cloud applications.

A ready-to-use MTP toolbox

The engineer can implement these unfamiliar steps manually, but this would be unnecessarily complicated and time-consuming. Instead, industrial automation software offers a far better solution.

The zenon MTP studio software platform includes a suite of tools designed to support equipment vendors that supply PEAs, and help pharmaceutical companies integrate PEAs into production lines. Engineers can benefit from zenon MTP editor and zenon MTP validation, which make it possible to easily-configure MTP services, define input and output (I/O) parameters and design the PEA HMI.

Once the configuration is ready, the user can validate and create their MTP file.

The file is then ready to be delivered to the process orchestration layer (POL), where they can refer to it as an “ID card” for the bioreactor.

So, automation software allows the three steps towards integrating a bioreactor to be automated. Through this process, pharmaceutical manufacturers can integrate bioreactors and other innovative PEAs into their bioprocessing lines securely and quickly. In doing so, they can achieve faster process designs that are necessary to overcoming the cost pressures, and other market challenges, they face.

To learn more about how zenon automation software from COPA-DATA can benefit modular production and mass customization, visit this website.