Matara UK Ltd, specialist in automation, pneumatics and linear motion products, has designed and built an XY linear system for Layton Technologies Ltd. capable of providing speed and precision accuracy for a PCB coating machine, that is also able to endure corrosive atmospheres.

Layton Technologies Ltd. is an international leader in the design and manufacture of machines for cleaning, drying, surface treatment and material recovery for precision cleaning applications. For one electronics customer, Layton was asked to develop a machine for conformal coating of PCBs that combines precision and reliability. To achieve this, Layton turned to Matara to deliver a linear motion system that could give a smooth, precisely controlled XY motion in and out of the coating tanks.

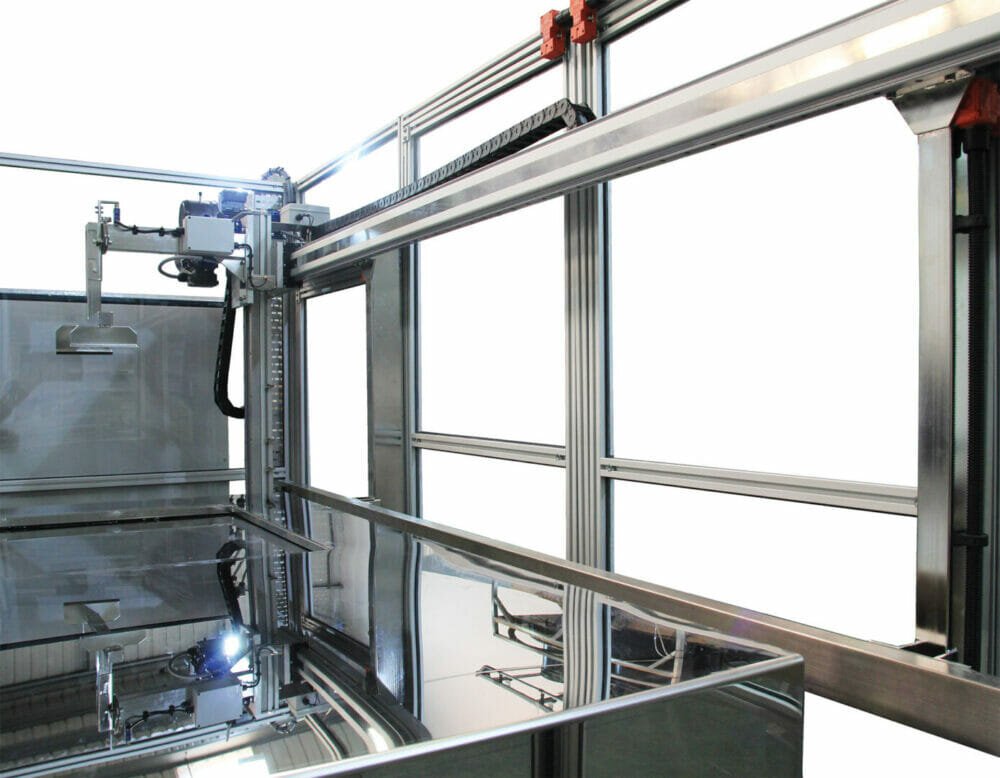

To achieve this, and avoid any spillages during operation, Matara selected an MTS Guided Belt Driven Actuator for the horizontal axis. Belt driven actuators perform better than ballscrew actuators at higher velocities and also in applications that require a long stroke, making it a suitable choice for this system. The MTS unit was particularly suited for this application due to its construction, which features an internal rail system and, externally, a rail and two carriages either side of the piston, providing a high degree of rigidity and accuracy. A MOD3 Stainless Rack & Pinion Actuator also forms part of the XY configuration, applied vertically. It is also rigid, can lift heavy loads and has a long 810mm stroke.

Contained within the workings of the machine is a second vertical application, consisting of a Matara MTV Ballscrew Driven Actuator size 65 x 620mm. This comes with a motor side drive and worm gear box with a 5:1 ratio.

Matara also supplied air preparation components as part of a pneumatic circuit on the machine.

The entire linear motion system is enclosed by an aluminium framework, using 40×40 and 40×80 aluminium profile, with 5mm Polycarbonate sheets throughout, cut to size.

To withstand the harsh environment the machinery will be working in, which is subject to corrosive vapours from the coating process, stainless steel components have been chosen wherever possible and linear rails have been Armoloy TDC® coated, which provides corrosion protection equal to 440 series stainless steel.

Commenting on the decision to award this project to Matara, Vikki Breese, Business Development Manager at Layton Technologies puts it down to the excellent working relationship the two companies have enjoyed: “Layton have collaborated successfully with Matara on many projects where precision, reliability and flexibility of handling system has been paramount to the success of the project. Furthermore, we have always found the service excellent.”

Matara is part of Rubix, Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. For more information, please go to www.matara.com/, or contact Matara at [email protected] or on 01684 850000.