Automation expertise from FANUC has supported injection moulding firm Mitre Plastics to specify a flexible six-axis robot cell during its latest project for a white goods manufacturer. After first considering a cobot solution, Mitre Plastics has instead, with FANUC’s help, commissioned a faster, more cost-effective, and more flexible industrial robot system, helping the company to fulfil its contract with a major customer.

Located in north-east England and boasting a 50-year history, in 2019, Mitre Plastics was invited to quote for producing a high-volume part with a brass insert for a white goods manufacturer, requiring a repeatable, high-speed insert loading solution. To get an idea of how the part could be produced on its existing FANUC ROBOSHOT α-S220iB injection moulding machine, Mitre Plastics asked an unnamed automation supplier to scope out a conceptual solution.

“They suggested using a collaborative robot in conjunction with our existing injection moulding machine and three-axis robot to handle insert loading,” recalls General Manager Michael Breckon.

However, as an existing FANUC injection moulding customer and therefore confident in the company’s automation knowledge and expertise, Mitre Plastics decided to seek FANUC’s advice before committing to the cobot purchase.

An alternative approach

“When we took the proposal to FANUC to discuss providing additional hardware and integration work for the solution, it raised questions over how it would work in practice,” says Michael.

The review highlighted a number of limitations with the proposed solution, with FANUC’s engineers concluding that this application was not wholly suited to a cobot. FANUC’s senior integration engineer James Pointer explains why:

“Firstly, collaborative robots are intended to work unguarded, but in this case, a guard was required, adding cost. Secondly, the proposal was to mount the cobot on the moulding machine at head height, which would not comply with health & safety guidelines. And thirdly, cobots are inherently slow, whereas the key with injection moulding is to minimise mould open time for maximum productivity.”

A seamless partnership

Instead of a cobot, FANUC proposed a simpler, faster, more efficient and more flexible solution, comprising a six-axis robot cell.To assist in this alternative approach, it engaged Hi-Tech, its long-term strategic partner for injection moulding handling and integration. The two companies worked seamlessly to devise a solution that involved replacing the existing three-axis robot with a side-entry six-axis robot. This would take four inserts from a bowl feeder, enter the moulding machine through the side door, place the inserts into the mould in the correct orientation, demould the finished component and conduct post-mould checks – all within the specified cycle time.

“With the aim of reducing cost and complexity to the existing system, we designed a self-contained industrial automation cell,” says James.

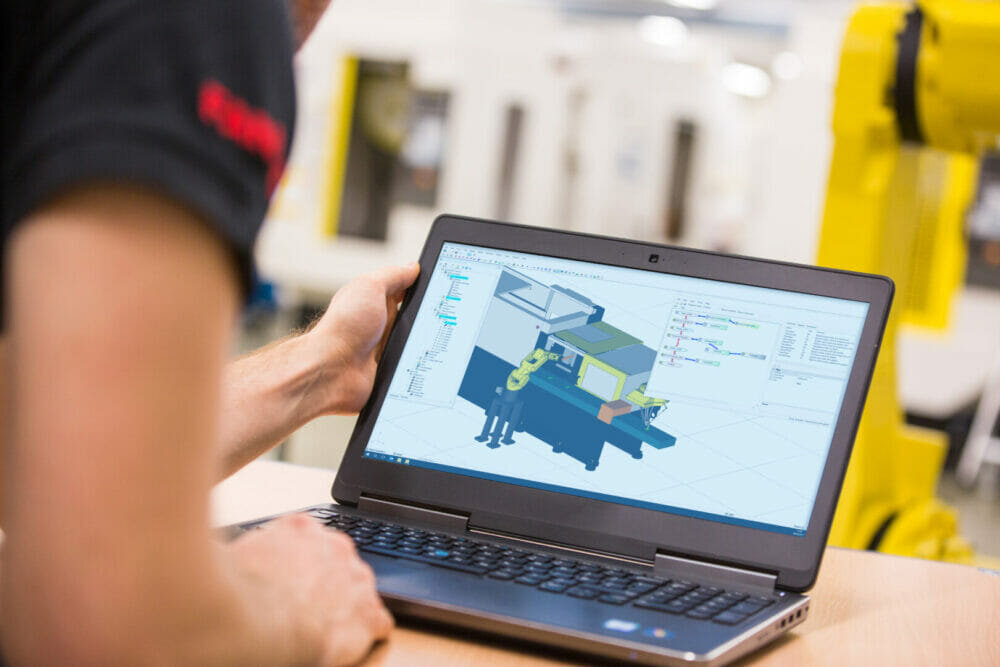

With all parties happy with this concept, FANUC then simulated the cell on its proprietary ROBOGUIDE software and completed cycle time studies to determine the optimum robot model for the best price:performance ratio over the system’s lifetime.

“ROBOGUIDE allows us to investigate how different specifications can influence life cycle. These simulations told us we needed a 1.8m reach and a 35kg payload to accommodate the actuation and sensors needed for a double-sided gripper, which led us to the M-20iD/35,” says James.

Flexibility foremost

Flexibility was also an important consideration in this project as, although the contract was large, other work still needed to be kept on the moulding machine. This made a six-axis robot ideal, as James explains:

“As the name suggests, with a three-axis robot you have three axes of movement: up and down, left and right, forwards and backwards, so when the gripper comes down you can’t change the angle. A six-axis, in comparison, gives you full rotation and therefore free movement. For the manufacture of plastic parts with over moulded inserts, this freedom of movement is invaluable, as precision and accuracy are key to successful production.”

Morale boost

While the new proposal seemed ideal, one problem with a change in approach at this stage was that the original cobot solution had already received capex approval. However, this concern was soon assuaged when the new system came in at a similar cost, as well as giving Mitre Plastics six-axis robot capability and the option of re-tasking the three-axis robot elsewhere in the factory. Hurdles overcome, the cell was installed just before Christmas 2021, ready for production start-up in mid-2022.

“This was a long-term investment that supports the company’s ongoing commitment to technical development. It also demonstrated our commitment to the customer and gave them reassurance that we can take their requirements and translate them into a reliable and efficient manufacturing system,” says Michael.

Six-axis reservations

Despite the company’s faith in FANUC, at the outset of the project Mitre Plastics harboured doubts over its ability to handle the six-axis robot.

“We’d been aware of six-axis technology for some years but were concerned that it was difficult to programme, that our staff wouldn’t have the necessary skills and that we would end up relying on external expertise,” says Dave Veal, Technical Manager at Mitre Plastics.

However, Dave is pleased to report that these doubts were unfounded: “The programming software has evolved; we’ve found it to be straightforward and logical. Plus, the assistance we’ve had from FANUC has been excellent – our engineers have been able to pick up the phone and get on-demand support whenever they’ve needed it. What we have now is a better solution. We’re really starting to see the benefits of six-axis technology.”

Gate removal

For Mitre Plastics there is a further advantage associated with using a six-axis robot on this application, relating to gate removal. A secondary operation performed by the three-axis robot had been the removal of gates (plastic left on the mould) using pneumatic cutting tools; however, this required several cutters set at different angles.

“The six-axis has given us greater flexibility when removing gates from products. Instead of having to use several different cutters set at different angles we can now offer the part to one cutter alone. That makes quite a difference in terms of costs and changeover time,” says Dave.

“We would certainly consider FANUC for any injection moulding or robotics project in the future and would definitely look at six-axis versus three-axis robot technology when designing a general purpose cell,” he adds.

Michael concurs: “We are always looking to develop our capabilities through technology – we must, in order to remain competitive. That includes pushing harder on the technology on and around the moulding machine to produce parts to customer specification every cycle and minimise labour requirements. The robot is becoming the central hub for the thinking around the machine and the more sophisticated the robot, the more we can do to remain competitive,” he says.