Deloitte recently found that four in five consumers are willing to spend up to ten per cent more for an item of clothing if it is personalised. In response to this, businesses are looking to change their assembly lines to keep the customer happy. But, is it possible to personalise every product without increasing costs? Here, Jonathan Wilkins, marketing director of industrial obsolete parts supplier EU Automation, explains how manufacturers can improve productivity by increasing flexibility.

Digital, internet-connected devices mean that consumers can dictate exactly what they want — more customisable products. As manufacturers invest in more sophisticated automation and modernise processes, they can begin to offer these products to customers.

Retail companies are beginning to see the benefits of personalisation. Larger companies, such as Moonpig, became successful after offering personalised greetings cards and gifts. However, smaller companies also benefit from mass customisation. Kennedy City Bicycles, for example, builds made-to-order bikes in London that customers design themselves online. However, is it possible for manufacturers to mass produce these personalised items without incurring excessive costs?

Flexibility in manufacturing

Mass personalisation requires a flexible assembly line that increases variability without compromising on quality. Manufacturers may want to increase flexibility to increase the product range, improve productivity or change the order of production.

A manufacturing system needs certain capabilities to be considered flexible. The system must be able to identify and distinguish between different parts processed by the system. Also, it must be able to complete a quick changeover of operating instructions and workers must be able to adjust the physical set up of the assembly line.

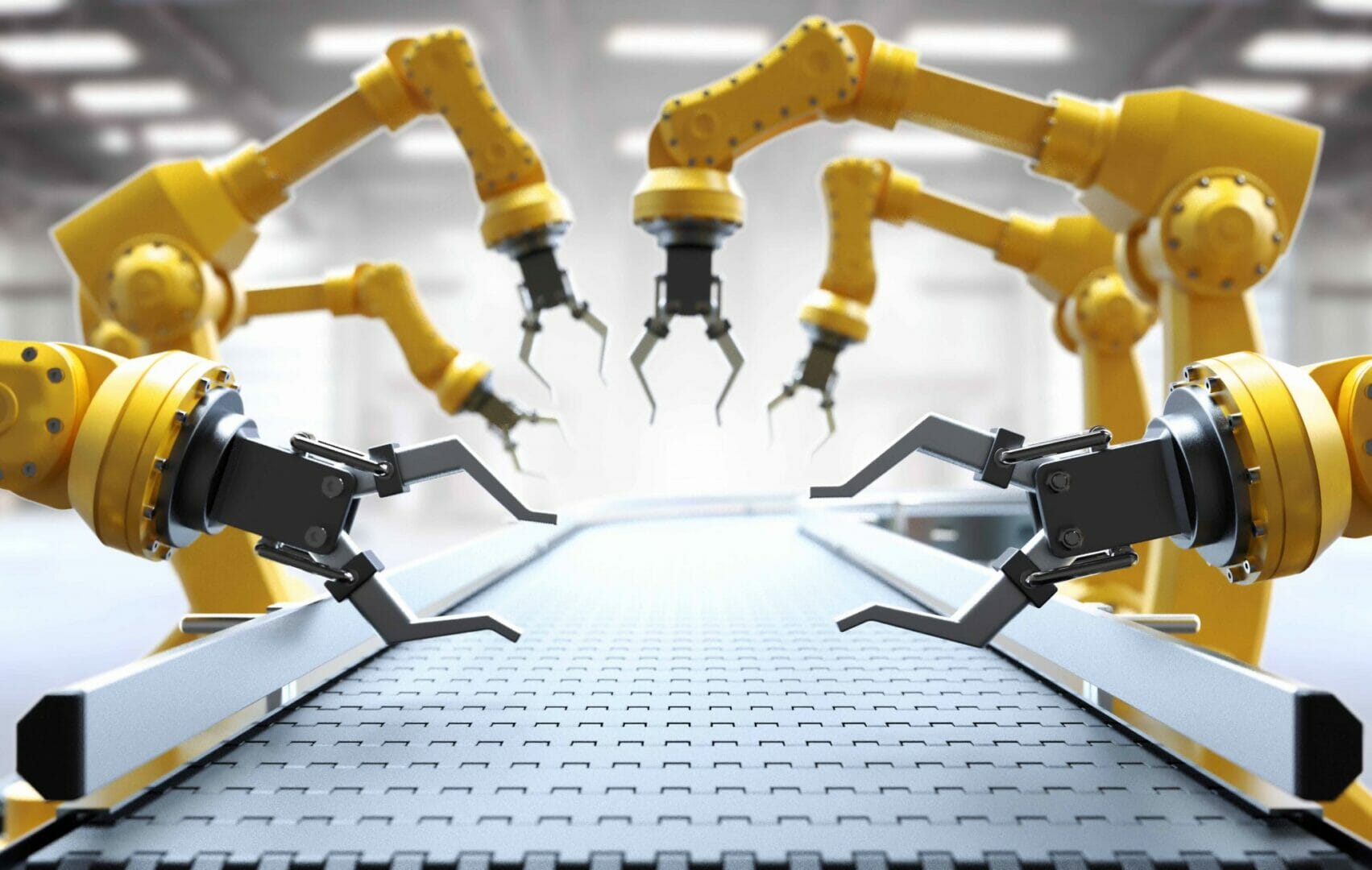

A flexible manufacturing system (FMS) is one of the main ways that manufacturing facilities can improve flexibility. The automated system consists of a group of processing work stations connected and controlled by a sophisticated computer system. The system is capable of adjusting quickly to both expected and unexpected changes. These changes normally relate to two areas. Routing flexibility refers to the system’s ability to change and produce new product types and change operation order. Machine flexibility is the ability to use multiple machines to perform similar operations, while adapting to large-scale changes such as volume and capability.

Facilities managers should use a FMS to quickly adapt processes when there are any problems such as bottlenecks, reducing the risk of unplanned downtime. Reduced delays make production time faster, ultimately increasing customer satisfaction.

Consumers have higher expectations and want a personal experience every time they order a new product. Flexible manufacturing is all about meeting these needs by creating a system that can adapt to change. As customers are willing to pay more for personalised products, manufacturers should invest in a flexible manufacturing system to keep up with the retailers that are already succeeding in the personalised product market.