A new interface for AC .2 actuator controls now allows AUMA actuators to be integrated into PROFINET networks, giving the actuator manufacturer a second Industrial Ethernet-based networking option alongside Modbus TCP/IP.

The new interface meets the requirements of PROFINET specification 2.3 and supports Conformance Class B (CC-B). Rates of up to 100 Mbit/s are possible. Implementation into line and loop topologies is facilitated by the integrated switch function. Loop topologies additionally provide redundancy via the Media Redundancy Protocol (MRP). Physical connection is made via field-assembled RJ45 connectors. Commissioning, handling of actuators, and fault diagnostics are easy and convenient, thanks to features including automatic address assignment.

AUMA actuators with a PROFINET interface integrate smoothly into network infrastructures, and can be identified and addressed by device name or IP address from any point on the network. An integrated web server allows swift and easy performance of connection tests, status requests and fault diagnostics at any time. All operation commands and feedback signals offered by the Profibus DP protocol are available to AC actuator controls thanks to the standardised device description (GSDML).

AUMA actuators with a PROFINET interface integrate smoothly into network infrastructures, and can be identified and addressed by device name or IP address from any point on the network. An integrated web server allows swift and easy performance of connection tests, status requests and fault diagnostics at any time. All operation commands and feedback signals offered by the Profibus DP protocol are available to AC actuator controls thanks to the standardised device description (GSDML).

“We are currently observing an increasing trend in process automation towards robust and versatile Industrial Ethernet standards, combining the advantages and functions of common fieldbus protocols with the speed and proven design of Ethernet-based technologies”, says Werner Laengin, Senior Product Manager at AUMA. “With the new PROFINET interface, AUMA is maintaining its leading role in providing field devices with state-of-the-art communication technology.”

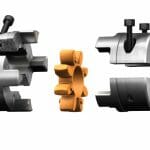

The PROFINET interface is available for SA multi-turn actuators and SQ part-turn actuators with AC integral actuator controls. It can be ordered as of now.

For more information, visit: https://www.auma.com/en/products/communication-systems/fieldbus/