The idea, developed by a motor designer at the end of the year 1980, was as unusual as it was plausible. If you took a casted and mechanically machined connecting rod, with a notched bore, and deliberately cracked it along the notch, two halves with positive locking and accurate fit were produced. At the same time costs were saved, since the separation surfaces did not need to be extensively machined.

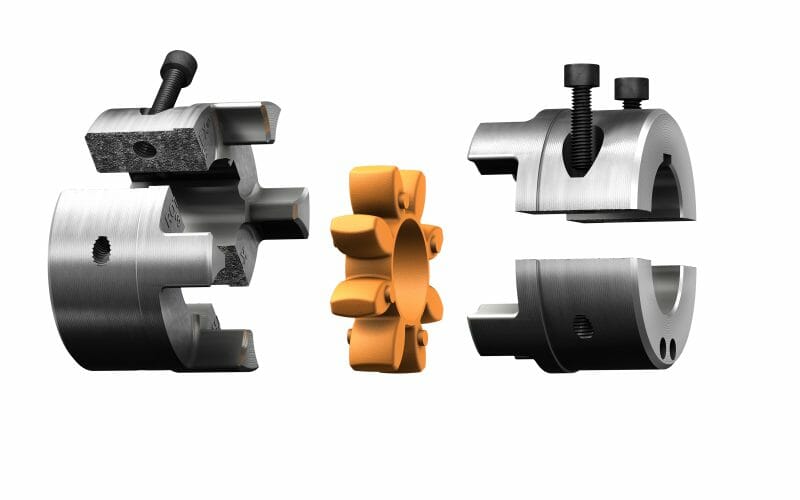

KTR’s ROTEX S-H uses the same production idea and, as a result, is a cost effective solution for power transmission applications with limited assembly space. The major benefit of the SH’s 4-screw spilt hub assembly is that it can be radially assembled, which eliminates the need to shift drive or driven ends ensures alignment of the system is maintained.

The cracking process results in two cast iron hub halves with cracked surfaces that are unique to each other. The two hub halves are remarried by way of two assembly screws, without a loss in performance or reduction to the overall power transmission torque rating.The S-H coupling is ATEX approved, available in cast iron material and features all of the beneficial characteristics of the standard ROTEX jaw coupling design, preferred in industry since it’s initial design by KTR in 1965. The ROTEX design offers torsional flexibility, for positive torque transmission, with effective damping of operational vibrations and shocks and capable of handling axial, radial and angular misalignment.

The cracking process results in two cast iron hub halves with cracked surfaces that are unique to each other. The two hub halves are remarried by way of two assembly screws, without a loss in performance or reduction to the overall power transmission torque rating.The S-H coupling is ATEX approved, available in cast iron material and features all of the beneficial characteristics of the standard ROTEX jaw coupling design, preferred in industry since it’s initial design by KTR in 1965. The ROTEX design offers torsional flexibility, for positive torque transmission, with effective damping of operational vibrations and shocks and capable of handling axial, radial and angular misalignment.

Polyurethane inserts of 95 and 98 Shore A hardness, and 64 Shore D (Green) hardness, are offered as standard, allowing the coupling to achieve a power range of between 7.5 – 4500 TKN for sizes 14 through 90.

KTR U.K. Ltd

Tel: 0114 2587757

Fax: 0114 2587740

Email: [email protected]

Web: www.ktr.com