A state-of-the-art surface treatment, Seal-Glide® Medical, which improves the friction characteristics of elastomer seals, will be showcased by Trelleborg Sealing Solutions at Making Pharmaceuticals in Coventry, England. The pioneering process boosts the stick-slip properties of elastomer seals, while having little or no effect on the performance of the compounds the seals are made from.

As a result of the innovative process, seals can be coated thinly to just a few hundred nanometers, up to 50 times less than standard coating thicknesses. Seal-Glide® Medical facilitates the production of medical devices through automated assembly in high volume and withstands harsh sterilization regimes commonly used in healthcare environments.

Andreas Schmiedel, Technical Manager for Healthcare and Medical in Europe at Trelleborg Sealing Solutions, said: “Our new surface treatment, Seal-Glide® Medical allows us to coat classic O-Rings and complex molded parts wafer-thin in the nano-scale range. As a result, the original elastic properties of the elastomers are virtually unaltered but the seals have a higher service life due to reduced wear when in motion or on start-up.”

The coating is ideal for use in healthcare and medical applications due to its high level of stability, making it resistant against sterilization with gamma radiation, ethylene oxide and hot steam, which is essential for the multiple use of medical devices, fermenters or syringes. Importantly, the process satisfies the strict requirements for medical, bio-technology and pharmaceutical applications as prescribed by the authorities in America and Europe.

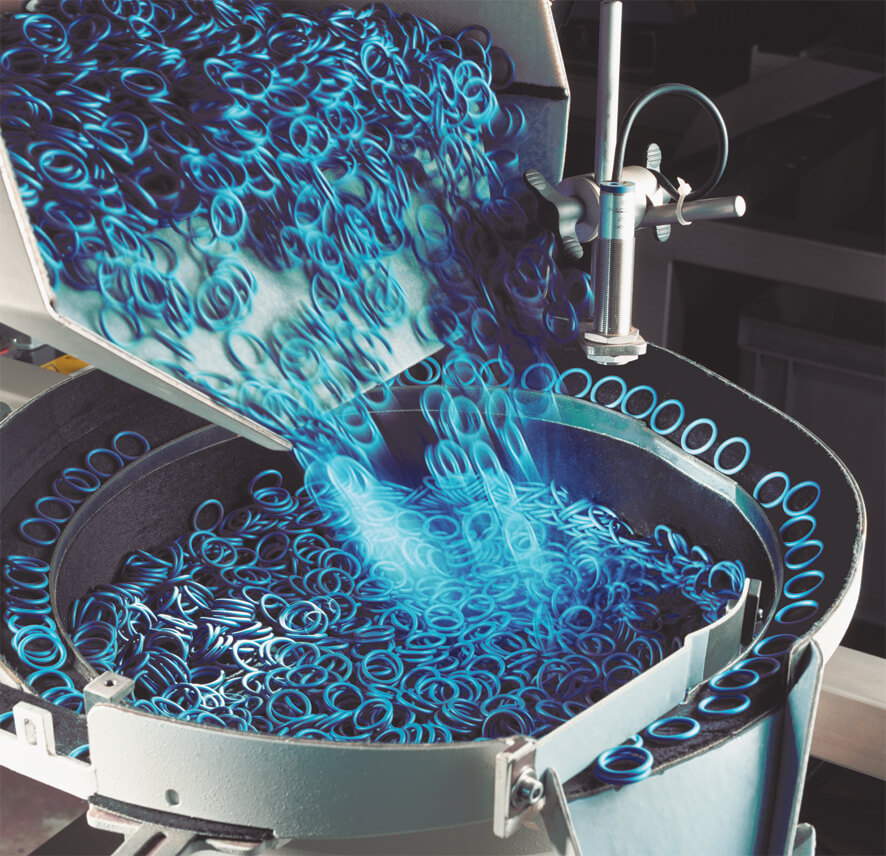

Mr Schmiedel added: “As medical devices are often produced in high volume, automated assembly is extensively used in the industry. When coated using the Seal-Glide® Medical process, O-Rings or complex molded parts can be installed more easily and securely in components due to better separation of the seals. Feed issues are minimized, reducing the probability of production stops.

“Another advantage of the Seal-Glide® Medical is that due to its thinness, the coating has a high level of transparency and does not cover the original color of the elastomer. The color of seals can play a central role in assembly. O-Rings are mostly black, but are often dyed in order to visually highlight differences in composition, diameter, thickness or positioning within a component. With our innovative coating, this color coding is retained, even after the coating.”

The process will be displayed as part of Trelleborg Sealing Solutions stand (317) at the forthcoming Making Pharmaceuticals exhibition, to be held at the Ricoh Arena in Coventry, England, from April 24 to 26.