HARTING has developed a range of miniaturised power interfaces with integrated electro-optical conversion, enabling customers to save time and money by combining electrical connectivity and optical transmission in the same module.

The new interfaces are designed for use with powerful electric drives controlled by IGBT (insulated gate bipolar transistor) semiconductor elements. In order to achieve the necessary galvanic isolation between the controller and driver board, data is transferred via fibre-optic cable. Electric motors with more than 500 kW output, such as those used in ships, trains or pumping stations, use IGBT semiconductors for speed regulation. These can switch large loads using very low control power.

Since insulation and voltage requirements are very high, plastic optical fibres (POF) transmit the signals required for IGBT control. The POF fibres ensure interference-free and galvanically isolated signal transmission.

In order to simplify the connection of POF fibres, as well as saving space on the controller board and reducing downtime during service, HARTING has integrated the electro-optical conversion process into application-specific connectors.

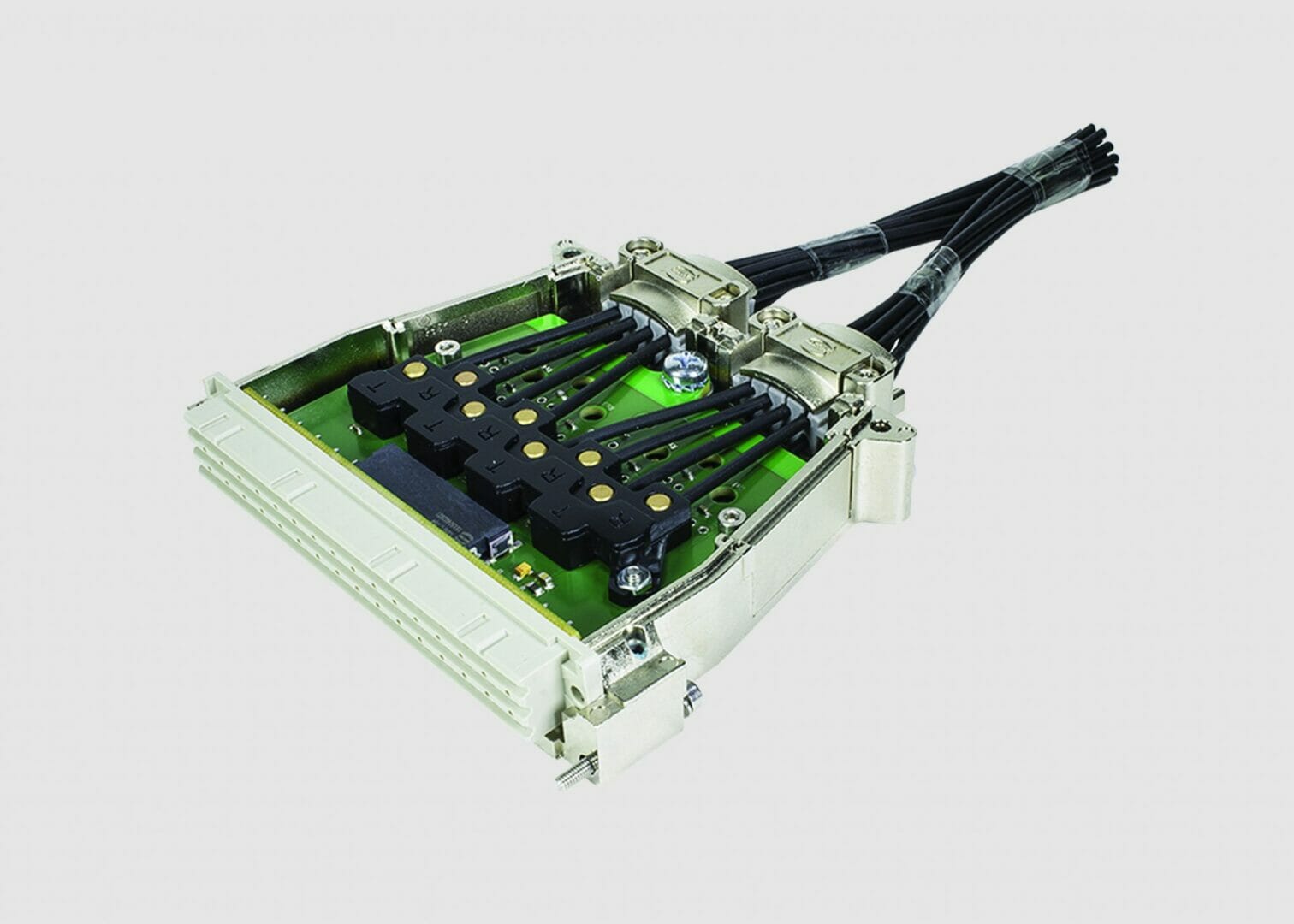

For traction control on trains, a solution for up to 16 optical channels is available in a DIN D20 metal housing. In harsh industrial environments, a Han 10A housing variant with IP 65/67 protection offers up to eight channels. The range is completed by a pluggable 8-channel module for direct connection to the circuit board in the switch cabinet.

In all variants, the fibres are connected by means of a metal clip which attaches them without any additional optical contact. In addition to the possibility of field assembly, HARTING offers the modules as ready-to-use and tested cable assemblies – a compact, robust and service-friendly solution that provides the user with security and cost advantages.