As a product with a history spanning some 60 years, since its first introduction in 1958, Reich’s Multi Mont coupling range has today established itself as the driving force behind power transmission applications across multiple market sectors.

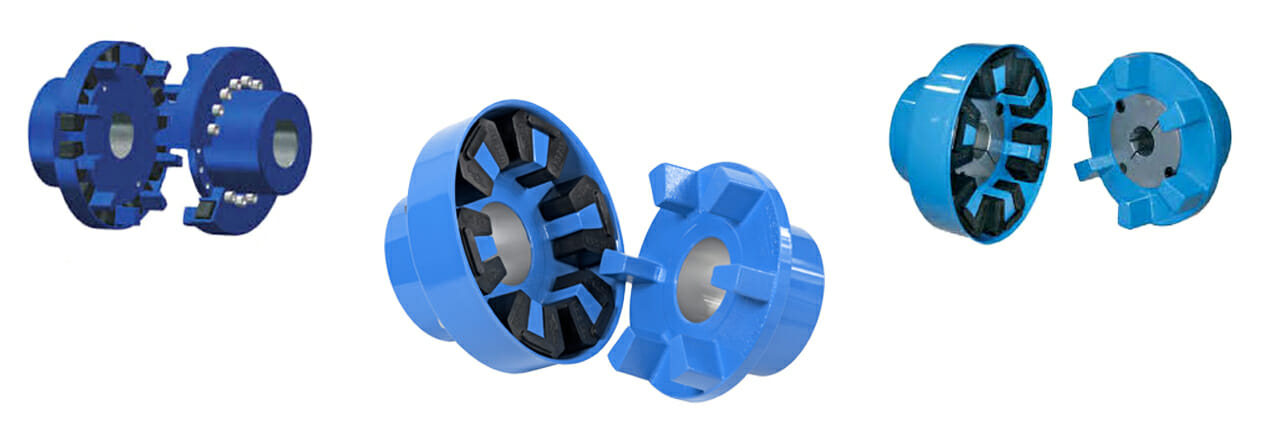

The three main Multi Mont torsionally flexible claw coupling product variants: SELLA, DEKA and GIGANT, have between them amassed a multitude of installations in many demanding environments. In this article, Reich Drive Systems UK’s General Manager, David Proud, reflects on the extensive and diverse capabilities of this firmly established range of drive couplings.

The Multi Mont product range features in a long line of innovative drive couplings for mechanical power transmission applications developed by Reich Kupplungen GmbH. These pluggable claw couplings have undergone regular updates over the decades, enabling them to maintain their reputation as market leaders in drive technology. Having a variety of different types, there is invariably a Multi Mont coupling for every type of application.

The Multi Mont flexible jaw coupling is a clever and easily customised concept for connecting shafts within a drive train to transmit torque. The full range now covers a vast torque capacity from 40Nm right up to 1,000,000Nm, using the GIGANT version, which is at the top end of the product offering.

Irrespective of model selected, the main benefit of the Multi Mont family of couplings is the ability to change the flexible transmission elements without the time consuming work required to move machinery and then re-align it afterwards. There is no need to uncouple the drive, as each variant is designed to allow easy access to the flexible transmission elements, which can then be removed and replaced radially. This concept generates considerable savings in time over alternative product types, helping to maintain the highest levels of uptime and efficiency.

Robust Construction – Made To Last

The Multi Mont standard range utilises Spheroid Graphite (SG) Iron for the hubs and flanges. SG Iron offers greater elasticity, resulting in a better and more robust coupling which is less susceptible to damage. The range also allows the incorporation off keyless clamping elements, either internal locking assemblies or external shrink discs. The keyless clamping method of locating a coupling hub on to a shaft offers many distinct advantages over traditional methods such as keyways, splines & thermal shrink fits.

Depending upon the individual product variant, a Natural / Synthetic Rubber mix or Nitrile rubber is used for the flexible transmission elements. Natural rubber is proven to be the best material for damping therefore Multi Mont couplings are ideally suited to applications where torsional vibration is present. Standard flexible elements have a temperature range of -40°C to 100°C, and for higher temperatures silicone elements with temperature range of -70°C to 120°C are available.

Over the decades, Reich Kupplungen GmbH has developed the Multi Mont flexible jaw coupling into a versatile product with many variants as standard, including shaft to shaft; shaft to flange; flange to flange; with brake drum or with brake disc versions, and also a standard version with the very popular taper bush centre. Innovations around the Multi Mont flexible jaw coupling continue with the recent development of a high-speed version made from high-grade aluminium, which is capable of speeds up to 20000rpm.

Designers & engineers have taken advantage of the unit’s adaptable design to easily combine the coupling with other mechanical power transmission products such as torque limiters, clutches, freewheels and fluid couplings to create bespoke drive solutions. Customers who have demanding applications requiring ATEX certification can now specify the new standard ATEX Multi Mont Sella flexible jaw coupling.

Given the extensive nature of the product range, and its impressive heritage, it is not uncommon to find examples of Reich’s Multi Mont couplings being used in many challenging applications within marine, off-road vehicles, pumps & compressors, quarry equipment and other general industrial roles.

The growing demand for electric and hybrid drive vehicles has seen the Multi Mont range diversify yet further, where it can be found at the heart of many new drive and propulsion systems.

The features of Reich’s Multi-Mont Drive Coupling can be seen in their new 3D Animation Video which can be viewed here:

https://www.reich-uk.com/news/mms-coupling-3d-animation

For more information please contact:

Mr David Proud

General Manager

Reich Drive Systems UK Limited

Unit 4, Bankside Business Park

Coronation Street

Stockport

Cheshire

SK5 7PG

Telephone +44(0) 161 714 4191

Website – www.reich-uk.com