A large component of product assembly involves some threaded parts that need to be accurately screwed together in a process that is repeatable every time. This requires a form of “Intelligent Screwdriver” with position, force and torque feedback in both linear and rotary axes. It also needs to be accomplished at high-speed and act as a sensitive feedback device that can reject any faulty thread or assembly to maintain high quality control.

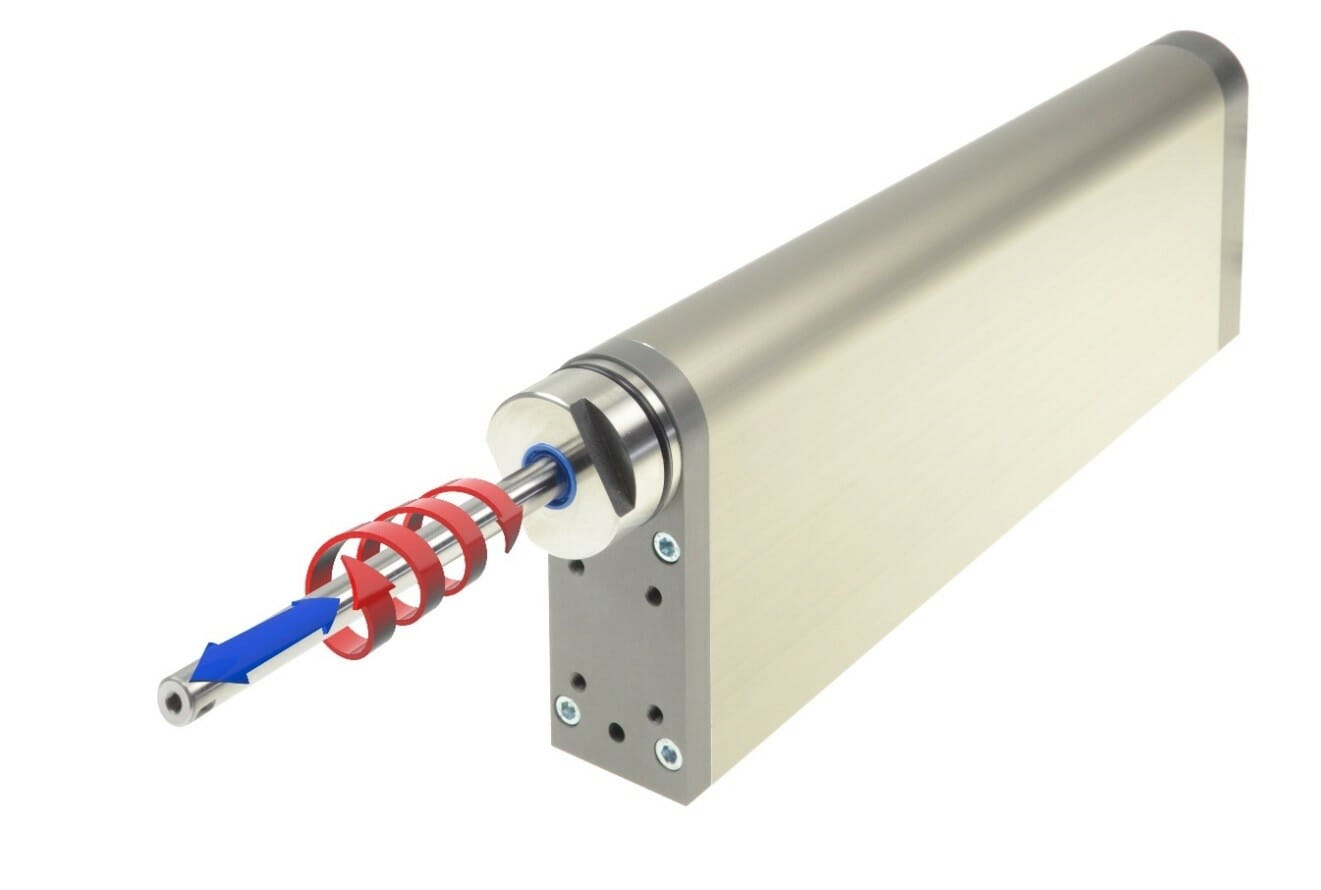

As a leader in the development of high performance linear motors, LinMot have in the last few years pioneered combined Linear and Rotary motors. These provide independently controlled linear and rotary motions on one shaft with great advantages for Screwing and Assembly applications.

The growing PR01 and PR02 Linear Rotary family of motors now offer extra features such as torque sensing and force measurement. These can be used in combination with linear and rotary position and velocity measurement for detecting all of the conditions show in the diagram.

There are many types of screw assembly such as attaching cartridge caps, checking and pre-assembly of threads and locating and tighten of screws. The process in each case are similar but with differences that need to be catered for.

A typical procedure involves:

- Finding the screw/cap

- Finding the engagement points or slot

- Screwing to a position or torque

- Checking the force and torque during assembly

- Retracting back ready for the next cycle

With closed-loop servo control and force and torque sensing throughout, very repeatable and high quality assembly can be achieved. Any poor thread, misalignment or out of tolerance parts can be detected early in the process. It could either be attempted again for example with another screw or cap or rejected before wasting any more time on the assembly.

This level of continuous monitoring of both linear and rotary axes is a huge step up in control and quality from using more conventional clutch and pneumatic methods combined with simpler motor control.

As the Linear /Rotary motor is fully programmable, the parameters can be changed on-the-fly so that the same assembly station can carry out different operations and provide feedback on each one. A great advantage with LinMot products is that most of the main PLC networks are available on the drives such as EtherCAT, Profinet, Ethernet/IP, Powerlink and many others. This allows this flexibility of control and information feedback to be integrated into almost any control system very easily.

For more information, please contact Quin Systems, the UK LinMot distributor on 0118 977 1077 or sales@quin.co.uk.

Website: www.quin.co.uk