By Emma Ryde, Rittal’s Product Manager for Industrial & Outdoor Enclosures

The journey towards digital transformation is a somewhat daunting one for many manufacturing companies. Rittal’s teams work in partnership with manufacturing and industrial companies to deliver IT infrastructure that supports digital transformation and Industry 4.0 technology, including edge computing platforms.

The team will be on-hand to talk about how companies implement rapid-deploying and secure IT for production facilities, at Data Centre World 2020.

The first step on any transformation journey is to clarify goals and agree a consistent use of terms.

There should certainly be an acknowledgment of the value of real-time processing through more IT and additional sensors. This opens the door to truly innovative applications, such as process optimisation, machine learning and predictive maintenance, delivered by big data analysis. These allow users to quickly identify any deviation from ‘the norm’, which in turn increases reliability of production processes.

Secure Location for IT

Deciding where to place new IT systems – such as edge computing – within a production environment requires input from a range of different departments: facility management, fire prevention and safety managers, production managers, IT managers and other specialists in network technology and production planning.

With such a large number of stakeholders, project managers need to start consulting at at an early stage of planning. There may be a number of existing spaces to choose from, or it may mean building a whole new facility to house the additional IT systems, but many businesses are able simply to retrofit IT systems within the manufacturing hall.

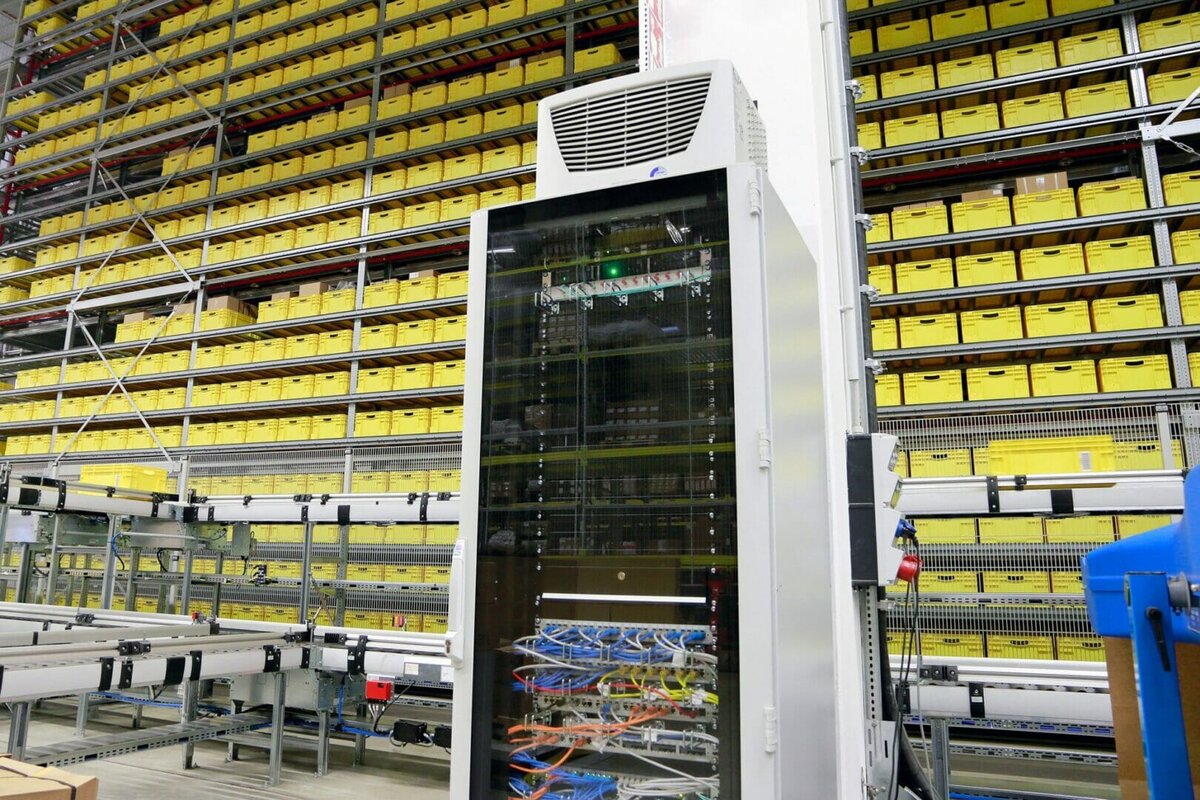

In one recent project that Rittal was involved in, the new IT system for the company’s automated production processes was placed on the second floor of the production hall using, special security rooms for the IT racks. However, the arrangement used a water-based IT cooling system, which carried the risk of a leak onto the manufacturing facilities located below. As a further security measure, therefore, leak detectors were installed in the IT racks and throughout the building to give an early warning to the facility management team of any problems.

Project managers of course will want to site the equipment at a location that is suitable from a technical security perspective and to ensure there can be well organised network cabling. It’s also important to maintain a reasonable distance from the manufacturing equipment in order to protect the IT systems from excess heat, dirt and vibrations.

Monitoring and Alarm Systems

Monitoring and alerts have to be accessible to all of the project participants, and this may require a review of an organisation’s IT security strategy.

For example, while companies typically find that their IT systems are able to send detailed alarm messages to control centres within the company, its firewalls might prevent the same information being conveyed to key outside stakeholders. These stakeholders could the manufacturer of the equipment, who – on receipt of status messages – are well placed to offer additional support.

Rittal’s teams worked with a manufacturing company to upgrade the IT cooling systems with the aim of lowering energy costs and increasing the reliability of their IT system. It meant that its firewalls had to be configured according to the data protocols to ensure that the cooling system functioned in accordance with the designated levels of safety and efficiency.

Monitoring Software

Any monitoring software (DCIM) that oversees production-related IT systems needs special protection. Such systems tend to have a the large number of interfaces and support a variety of protocols, which can make them vulnerable to cyber-attacks.

We advise clients to conduct network vulnerability tests to ensure the installation and the server platform are robust. Without this protection, it’s possible that a cyber-attack could cause major disruption, such as shutting down fans in an intelligent cooling system, or turning off switchable power distribution units (PDUs).

Setting Up Edge Computing

Not every production plant can be shut down in its entirety while work is in progress so, in these instances, it may be a good idea to use pre-configured IT containers that are pre-equipped with IT components. A company can then widen its IT capacities to decentralised production sites quickly and safely using edge data centres.

Rittal and our partners iNNOVO Cloud offer turnkey IT module and container solutions that enable an edge computing infrastructure to be set up for Industry 4.0 initiatives.These are essentially sturdy steel containers that house power distribution units, UPS, IT cooling systems, racks and, optionally, active components. It provides a quick and secure start to production, and has been employed by numerous companies worldwide.

For more information visit www.rittal.co.uk, www.friedhelm-loh-group.com, or on twitter @rittal_ltd.

Rittal’s expert team will be on-hand to discuss how to implement Industry 4.0 as well as digital transformation in manufacturing, at Data Centre World 2020 (Excel, London, 12-13 March 2019) at Stand D510.