Concept Controls Ltd and SEEPEX UK Ltd provide a perfect solution

A significant factor in baked goods manufacturing is the need to reduce the cost of raw material delivery into dough mixes. Modern research and process techniques have been used by AB Mauri, a major manufacturer and supplier of bakery ingredients, to produce a range of Enzymes, Bread Improvers and Enhancers in a highly concentrated form. These ingredients are highly effective, requiring very small amounts to be added to each batch.

To maximise the benefit of these concentrated products accurate dispensing of the ingredients is critical, both to ensure optimal ingredient performance, and to minimise overdosing (which can add to material usage and cost). Traditional weighing and Diaphragm Pump dispensing, even with the best of metering control, can lead to significant variations in the actual additive level to each batch of dough.

Solution

Although AB Mauri has considerable in house experience at developing the products, the related processes, and even the engineering of equipment, they wished to use an external engineering company with experience in Bakery and other process equipment to develop a solution that met demands for accurate dispensing.

Concept Controls Ltd (Waltham on the Wolds) were approached, and shown some of the original systems, a number of which had performance limitations with the latest developments in ingredients. After technical analysis of peristaltic, lobe and double diaphragm pumps a higher performance pump was sought to ensure accurate repeatable dispensing of concentrated ingredients from bulk containers.

During the research process the SEEPEX Progressive Cavity (PC) Pump, became a clear leader. The main benefit of the PC pump is that there is a sooth pulsation free delivery of material delivering repeatable accuracy of +/-1%. The flow rate is linear, proportional to motor speed and regulated by a simple speed controller over a very wide range. This was specifically useful as there is a limited time (Less than 25 Secs) for dosing of the A.B. Mauri products when operating on a standard Bread Mixer, hence a high rate of delivery is needed for rapid dispense, but a low rate of delivery for accuracy of dispense.

The pressure capability of these pumps is also very wide, and the Concept Controls Ltd system uses this to deliver a high pressure and high accuracy phase at the end of the dosing cycle. The pumps can also accurately dispense products with a wide range of viscosities.

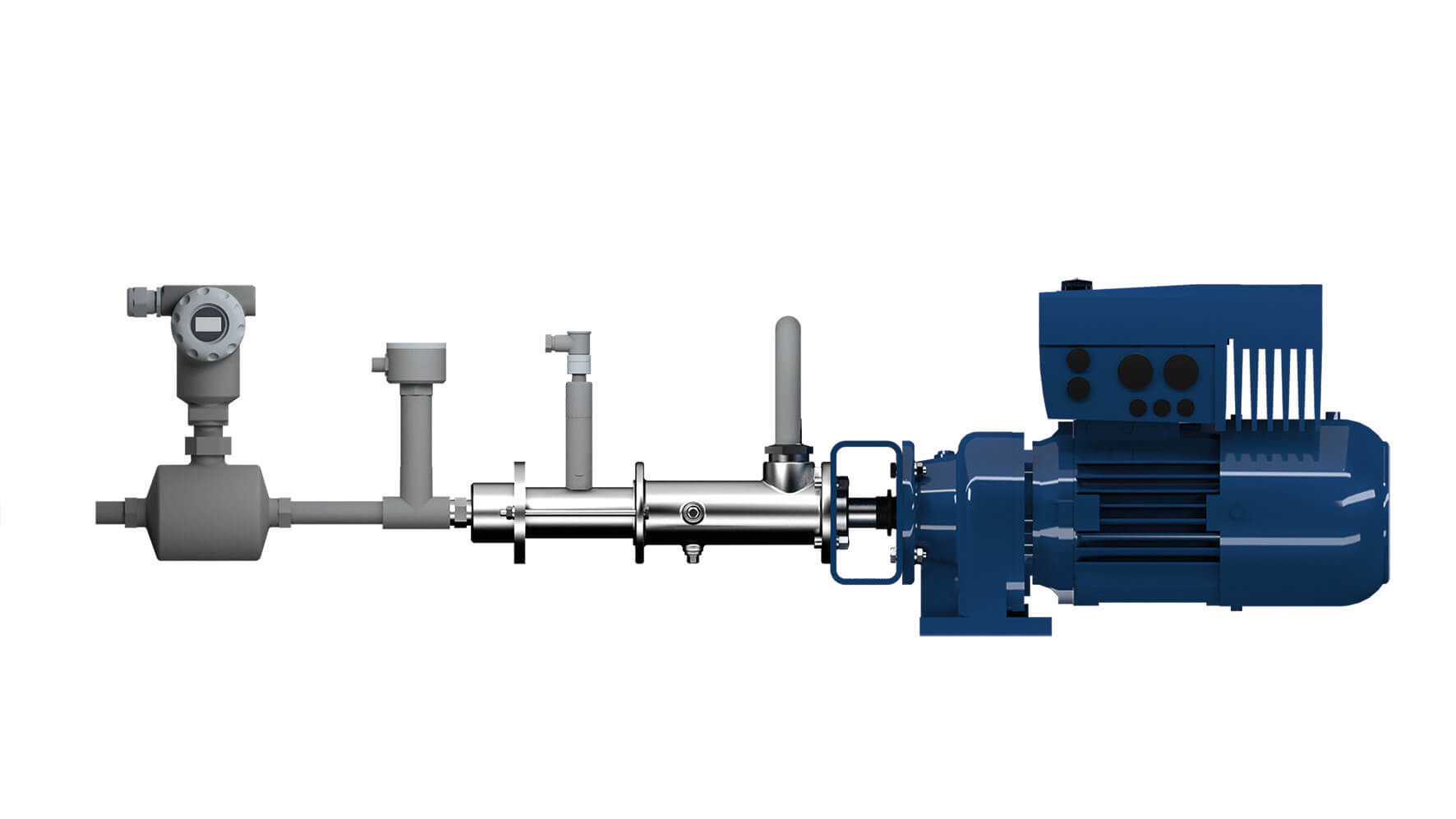

By coupling this high performance PC pump, orifice plates, and a very high accuracy Endress and Hauser Coriolis Flow meter, Concept Controls Ltd, in conjunction with their partner company PVSL Ltd. (Brierley Hill), are able to meet the challenging specification requirements for A.B. Mauri. The detailed design phase started with 3D Models of the proposed equipment generated by PVSL Ltd.

The result is an easy to apply Dosing System, that includes bulk frame storage for IBC containers (normally in Stores area), with buffer tanks to allow a practical regime for maintaining product stock. The SEEPEX PC pumps are more than capable of delivering the various products to a dosing frame mounted close to the Mixers, and hence through the associated mixer lids and into each batch of Dough.

The Dosing Frame is a small matrix of fast acting Ball Valves which allow the product to be fed either directly to the Mixer, or via the flow limiting orifice plate.

The net result is a system that can deliver as low as 50g into a batch of product, and also extend to several kilogrammes, all within the 25 second window, and every batch can be metered to the nearest gram.

The overall benefit to the end customer, is that they can rely on a very consistent product, with the advantages of the most modern process innovations, without the potential of overdosing (i.e. wasted product), overall enhanced quality and reduced overall scrap.