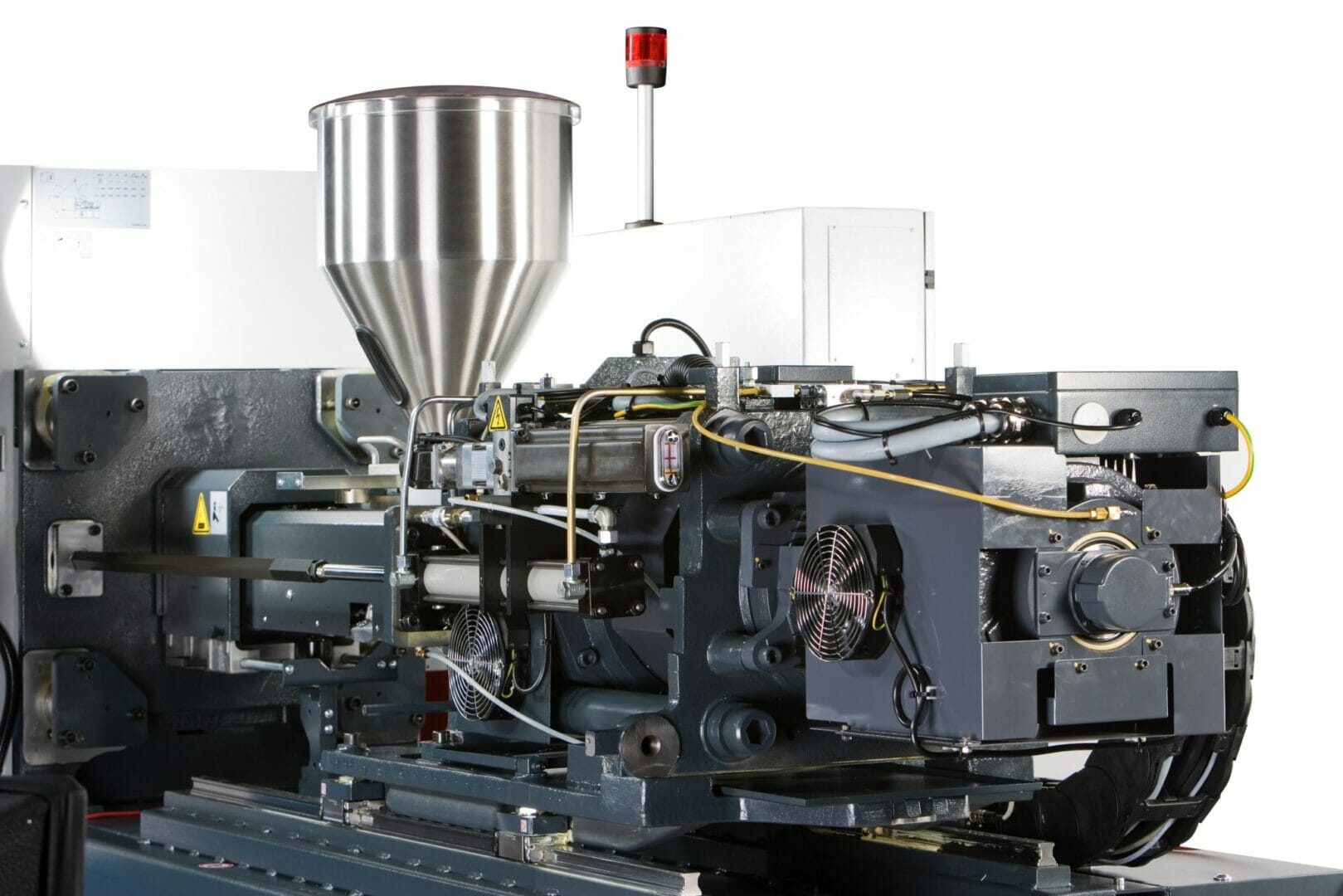

All-electric injection moulding machines have many virtues – greater precision, higher power density and lower carbon emissions. Yet there’s a preconception that these systems are more expensive to repair.

Keen to dispel this myth, Nigel Flowers, managing director of Sumitomo (SHI) Demag UK examines several of the metrics that counteract the reliability and service cost arguments and highlights where electric machines have the edge.

- Mean Time Between Failure (MTBF)

Many moulders discount high performance all electric machines on ticket price alone. However, not only has the gap between hydraulic and all-electric injection moulding machines closed considerably in the last decade, taking into account energy savings, productivity and reliability, further Total Cost of Ownership savings can be realised.

MTBF is probably one of the most rudimental reliability measurements. Yet, for equipment-reliant operations it is probably the most valuable KPI and the most accurate method for measuring machine availability and for determining maintenance schedules. Critically, this metric is not purely about monitoring machine downtime, but also benchmarks when machines are not performing at the cycle speed or quality expected. For an accurate picture you need reliable and accurate data.

With fewer moving and wear parts, the time lapse between one failure to the next is significantly less on all-electric moulding machines. For example, a recent study of Sumitomo (SHI) Demag machines under warranty found that on the IntElect2, MTBF was on average 4.2 years – double that of an equivalent hydraulic machine.

Additionally, it is not just the design of the machine, but also how an operative is repeatedly handling or interacting with this valuable asset that can influence MTBF metrics. A poorly executed repair job or implementing a quick fix and running the machine until it finally goes caput can just as easily result in a low MTBF result.

- Service time slashed by 80%

Electric machines are essentially less mechanically complex. With no flexing of hoses, sticking of valves and no hydraulic fluid to heat up or compress, there are fewer potential incidents in an all-electric system that could result in an emergency callout.

Studies conducted by Sumitomo (SHI Demag reveals that a 130 ton hydraulic machine needed 30 hours of routine service work, compared to just six hours for an equivalent IntElect model.

Hydraulic machines have long been regarded as industrial workhorses with an extensive service life. But they do require more care, which can be labour intensive and costly. Features such as tank vents and filters, if not serviced or replaced at regular intervals, can significantly impair performance.

Changing the oil filter is a routine maintenance task on hydraulics. Getting the timing right is essential. Left too late and contaminants could enter the system resulting in machine failure and spiralling repair costs.

Performing this filter change to the proper standard can take a couple of hours, production downtime that few moulders can afford. Additionally, hydraulic hoses should be regularly inspected and replaced at least every 10 years. Contamination is always a danger when undertaking a hose replacement. Being such a complex process, this procedure should be undertaken by a professional.

Hydraulic machines with an accumulator should also periodically have the bladder replaced. It’s also advisable to x-ray the accumulator for cracks every 10 years.

- Dynamic sustainable drive technology

Typically, electric machines have the reputation of being expensive to repair when they go wrong. This view is often based on the cost of replacing an entire drive system. Many moulding machine suppliers source their all-electric drives from external OEMs, which makes it more challenging to source component replacements, exchange or access service support. In the best case scenario moulders might be able to source and switch out a power or control module. Yet, in most instances sourcing a new complete drive is the reality. Which of course runs at a premium cost.

That’s one of the key reasons why Sumitomo (SHI) Demag designs and builds its own drive motors in-house, with an R&D centre dedicated to drive development. For customers, being able to source individual replacement boards is a more sustainable solution. Not only are these parts more accessible, with spares held for immediate shipment, flexibility is built into the design.

The company’s thinking is why replace three power modules, when the modular drive design allows you to replace just the one that’s outted. It is the difference between several hundred pounds, rather than a complete drive replacement running into a few thousand.

- Less pressure on infrastructure

The increased efficiency delivered by direct drives means that they use considerably less energy than hydraulic machines – in the case of the IntElect between 40% and 85% less than conventional solutions. And because electric drives generate less heat than their hydraulic counterparts, they require less cooling than conventional machines of a similar size.

This not only reduces the burden on existing infrastructures, but also lessens the investment when building or relocating to new premises.

- Thermal diagnosis

Regardless of machine type, it is imperative to monitor and routinely service moving parts, e.g. toggle systems, seals or bearings, which are subjected to varying degrees of wear and tear. One advance in this area is the use of thermal imaging. Because heat is a good indicator of wear, it is easier to spot the status of the moving parts.

Regular thermal imaging checks of electrical cabinets can give early indication of impending component failure, and are a quick and cost effective way to spot potential issues early on.

Using thermographic equipment, condition monitoring is included in Sumitomo (SHI) Demag’s annual activeCare check. Rather than a ‘best guess’ diagnosis, activeCare engineers provide quantifiable measurements to determine when equipment or parts are likely to fail in service.

Reducing costs, risks and disruption is the cornerstone of processing efficiency, with machine reliability sitting smack in the middle. For of all-electric machine service costs, the studies speak volumes with the facts outweighing the fiction.