New software for the design of shell and tube heat exchangers represents excellent value, making high powered tools more available to occasional users and professional heat exchanger designers alike.

AHED (Advanced Heat Exchanger Design), which was officially launched before Christmas, has been specifically designed to be both affordable and accessible to the widest group of potential users, while still offering detailed product design options.

AHED Software General Manager Arnold Kleijn comments: “We know that there is a large demand for heat exchanger design software which goes well beyond specialist manufacturing. For example, as well as academics and students, there are large contractors who design their own equipment but outsource the manufacturing, and there are also system integrators who would like to check designs as part of a wider process.

“To date, many of these users have been put off by the high costs of existing software options and many do not wish to pay for features which they do not need and may never use, or because they may only need to use the software once a month for example. AHED has been specifically designed around a modular, cloud-based architecture, with a range of licensing options, so that users can select the amount of functionality and the tools they require, from the essentials of heat exchanger design and the accompanying calculations, to options such as more heat exchanger types (like multi-pass and triple tube designs), batch calculations, fluid databases and project sharing tools. We are also able to offer engineering services such as design checking and training.”

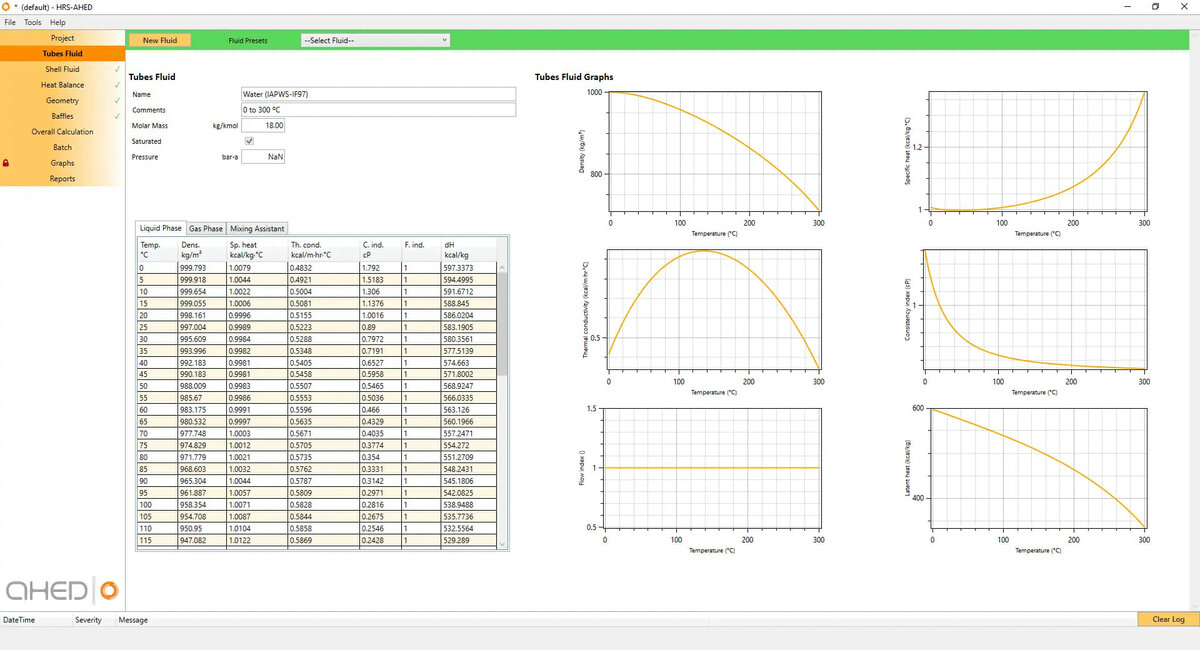

- AHED contains a database of 2,000 different fluids

- Once all the parameters have been entered, AHED performs all the necessary calculations

The software, which builds on 40 years of commercial heat exchanger design, covers a variety of processes (heating, cooling, condensation, etc.) and a range of heat exchanger geometries (tube in tube, triple tube and multitube) and provides additional features such as vibration analysis and easy data export and reporting using Microsoft Excel.

After specifying the main project parameters, users input the details of the product and service fluids (using the database of 2,000 fluids), together with the required heat parameters. Additional information such as tube geometry and baffles are then specified before the software performs the necessary calculations, complete with graphical representation of heat transfer rates under different conditions.

Arnold adds: “The whole system has been designed to be as easy to use as possible. Anyone with the appropriate level of engineering knowledge should immediately feel at home using the software, and this usability is helped by the in-built collaboration tools.

AHED is available for a commitment-free two-week trial at www.hrs-ahed.com. Licences start at just €125 for three months for the basic package.