Achieving a weight accuracy of 0.5 grams for every bread loaf, bun or burger bap is a huge advance for bakers seeking to maintain product quality, slash giveaway and waste and improve profit margins. Proven to save industrial bakers thousands of pounds every day, the Hestia, designed by inspection and weighing specialist Sparc Systems, is the highly efficient, automated checkweighing system that top bakeries across the UK can’t get enough of.

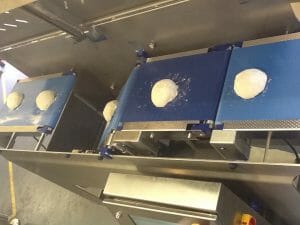

Inspecting up to 12,000 dough pieces per hour, the Hestia Dough Checkweigher provides bakers with unparalleled weighing precision and speed. So much so, as UK industrial bakers scaled up their automated production lines last year, several doubled their number of Sparc Hestia lines to guarantee uniform portion weights and unequalled accuracy.

Connected to an automated upstream dough dividing line, if a piece of dough is under or overweight by as little as 0.5 grams, the Hestia Dough Checkweigher automatically rejects it. Simultaneously, the machine’s advanced fibre optic controlled software communicates back to the dough divider in real time to adjust the position of the blade for the next batch. Typically inspecting 400 gram and 800 gram bread dough portions, Sparc engineers can pre-programme up to 500 different product codes, ranging from 150 grams to six kilograms.

Given that raw bread dough is live product that can change in temperature and density minute to minute, a number of processing variables also need to be factored in.

European Sales Manager Charlie Graham expands: “Changes within the dough itself places even greater importance on consistent weight monitoring before proving so we don’t bake anything that’s out of tolerance. Leaving until the final stage of the process could result in an entire batch being over or underweight. Costing a bakery over four hours of lost production time and thousands of wasted product.”

Additionally, a loaf may weigh 800 grams when baked, but in its raw state is 917 grams. If it is out of tolerance by just a few grams, dough can overspill and potentially spoil other loaves during baking. Plus, if one is overweight there will definitely be an underweight loaf in the batch. Maintaining consistent processing and checkweighing speeds combined with gentle handling can help to minimise wastage.

Proving the automation business case

Charlie estimates that in an industrial bakery plant, which easily produces 7,000 or more loaves an hour, switching from manual processing to automated checkweighing has saved some more than £1,000 a day. “Every big bakery started off doing all these dough dividing and weight check tasks by hand. Not only is this labour intensive, but also leads to variations in product quality. For commercial as well as artisan bakers, automated dough checkweighing allows for individual pieces that are off target weight to be removed and reworked, as well as providing corrective feedback to the dough divider.”

The result emphasises Charlie is a rapid payback on machinery investment. Several industrial bakeries testify that it has paid for itself in just eight weeks through reduced waste.

Data gathered via the Hestia management control system can also help to track uptime and address line inefficiencies. Using the swipe touchscreen, baking operatives can select the

statistical parameters most relevant to their operation. The easy to use graphical display automatically logs and reports Reject Integrity compliance tests. This intuitive digital interface also helps to significantly reduce set up time between each batch, reports Charlie.

For enhanced traceability, reports – configured by time, date or product code – can be downloaded and easily converted to common management reporting and software applications. Secure remote and authorised access levels enable bakers to troubleshoot, diagnose and resolve equipment issues on the spot to minimise system downtime and avoid production bottlenecks.

- HESTIA DOUGH CHECKWEIGHER

- HESTIA DOUGH CHECKWEIGHER

Built for breadCopy of

The Hestia checkweigher, reaffirms Charlie, was designed and robustly built for the bakery environment. Featuring always supported technology, the Hestia Dough Checkweigher also comes with a ‘last for life’ interlocked stainless steel top cover. To maintain the smallest footprint, the system measures just 200cm in length and 90cm wide, with the BRC-approved slide out reject box tucked neatly beneath the conveyor.

Rather than using compressed air, the Hestia features an electric servo drive. It results in a faster but more compact system to accurately and automatically reject over or under weight dough faster. One of the key advantages of this electric drive is the reject unit can be located beneath the hygienic, unclippable conveyor within the body of the machine, highlights Charlie. “This helps us to keep the unit compact and slimline compared to having the reject bin protruding to the side.”

With raw dough and loose flour coming into direct contact with the conveyor, cleaning to an allergen and microbiological level is essential. To support this process and prevent cross contamination, Sparc designed an innovative conveyor for the in-line Hestia Dough Checkweigher, taking Clean In Place (CIP) to an ultra-hygienic and time-saving level.

Comprising a tight-fitting conveyor and Sparc’s unique ‘no-tool’ maintenance innovation, the Hestia conveyor overcomes the longstanding industry challenge of loosening belt tension during machine sanitation. In just seconds operators unclip and disconnect the Hestia conveyor motor and lift out the entire conveyor assembly for maintenance and cleaning. This allows for the belt support frame to be fully sanitised too, reducing the buildup of loose product. Belt tension and alignment are instantly restored when clipped back into place.

“In the last 12 months, Sparc in collaboration with Fortress Technology has observed a definite rise in demand among bakeries for automated systems. Used for all sorts of dough applications from pizza to baps, French sticks to traditional loaves, the Hestia is repeatably proving its business case,” reports Charlie.