(16th June 2021, Arvada, CO, USA) ALIO Industries has a 20-year history working at the vanguard of nanometer-level precision motion control, something that no other motion control supplier can claim. Because of this, the company is at the vanguard of a revolution that is taking place in the world of in-vitro medical diagnostics, namely digital pathology where the demands on the accuracy of motion control solutions are as exacting as anywhere in industry.

Digital pathology includes the acquisition, management, sharing and interpretation of pathology information — including slides and data — in a digital environment. Digital slides are created when glass slides are captured with a scanning device, to provide a high-resolution image that can be viewed on a computer screen or mobile device.

Digital pathology is increasingly used by biopharmaceutical companies and clinical research organizations (CROs) to help to streamline drug development processes in discovery, pre-clinical, and clinical trials. It is also used for quantitative analysis of emerging companion diagnostics and novel theranostics (a combination of therapeutics and diagnostics). This opportunity has become especially relevant with the use of assays which are difficult to discern with the human eye, such as markers which exhibit diffuse staining characteristics across multiple cellular compartments of which, for example, only one may be clinically relevant.

The increasing complexity of such assays is driving the development of digital pathology solutions with advanced high-throughput image capture (brightfield, fluorescent or multispectral) coupled with pattern recognition to morphologically identify relevant tissue types and individual cellular compartments followed by the ability to quantify intensity of staining.

Bill Hennessey, CEO and Founder of ALIO Industries says, “Digital pathology — which has the potential to enhance the efficiency of pathology for both medical practitioners and patients — requires top-end nanometer-level precise motion control solutions to facilitate high-speed and high-quality scanning/imaging while maintaining a small footprint so as not to take up too much space in a lab/clinical environment. ALIO Industries is the only company that is in a position to fulfil all these criteria, specializing in motion control solutions that provide repeatable nanometer-level accuracy stages perfect for digital pathology applications. Motion control in digital pathology is an enabling technology, and is beyond the capabilities of most suppliers that have been building micron precision motion systems for years.”

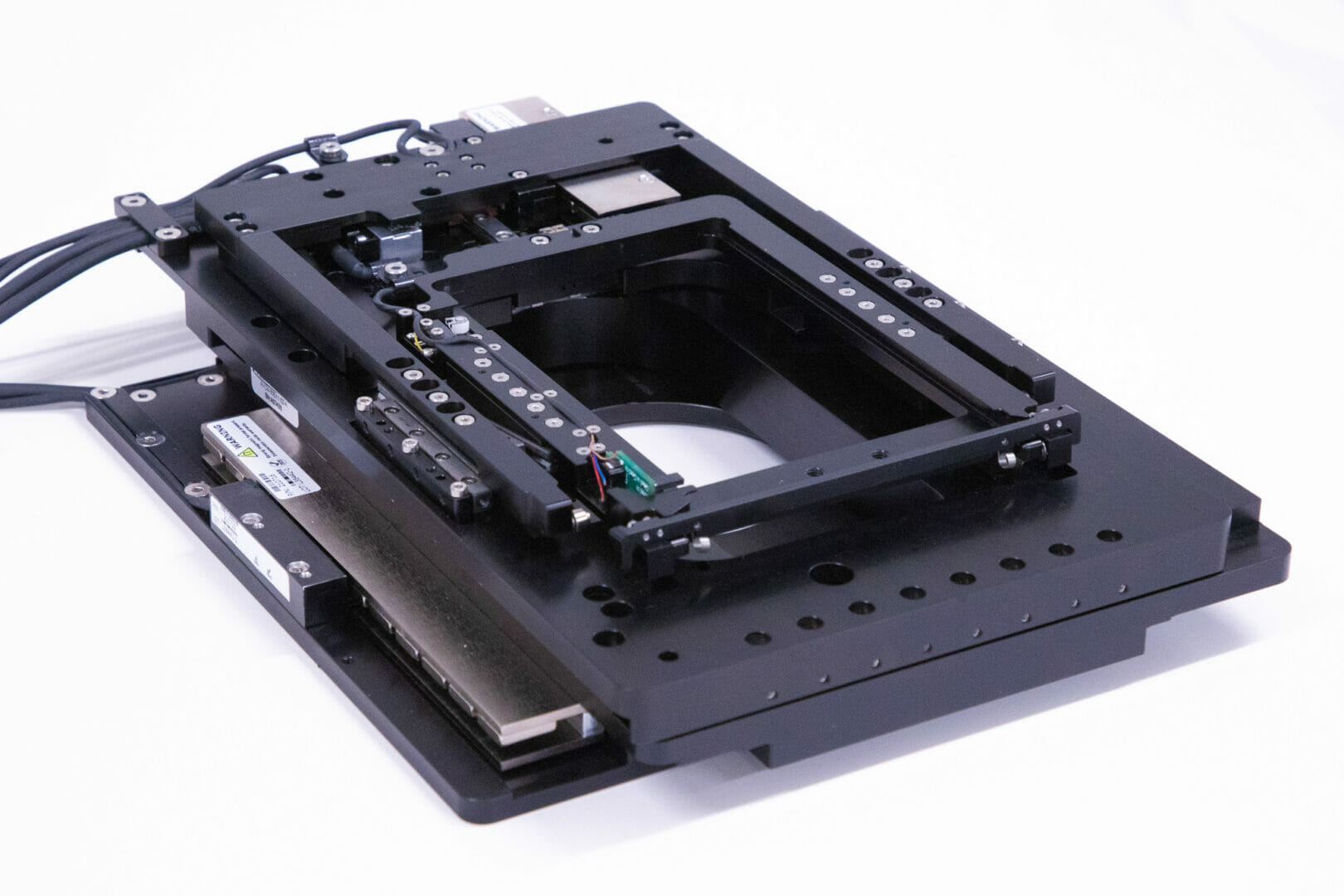

In the area of digital pathology, the xyz motion control stage moves the slides that are to be scanned underneath a fixed microscope or camera which captures images of the slides. The key is image capture at a high rate of speed with absolute focus on precision, which requires that the chosen motion control solution must combine smoothness (meaning highest possible image resolution), flatness (controlling the z-axis meaning maintenance of focus), and straightness (reducing overlap between scanning “passes” and increasing throughput).

Hennessey continues, “The motion control solutions that are required in digital pathology applications cannot be bought off-the-shelf. Attention must be placed on every component that is used in the custom stage to be used, and as such ALIO is a preferred supplier for a number of reasons, not least the fact that it is used to working with life science applications and uses testing techniques and processes that are unique to the life sciences sector. ALIO has one of the most advanced machine shops in the world, using state-of-the-art technologies in controlled environments to ensure optimised motion control products are manufactured. In addition, our in-house metrology department uses best-in-class measurement tools to allow us to prove complete adherence to design intent. In a world where nanometers are the focus, precise measurement and validation is key to successful motion control solutions, and so ALIO has 100%-part verification which is unique in the motion control industry.”

“It is because ALIO’s stages have industry-leading nanometer-level accuracy that they are used in digital pathology applications, where the requirement for image stitching of the scanned data is so vital (as is the case in top-end metrology systems). ALIO stages are characterized by the ability to move straighter than any other stages in industry, and therefore the resolution and accuracy of the data captured is superior, meaning reduced reliance on software to interpret and ‘guess’ what data readings are showing. ALIO provides completely customised motion control solutions and so is able to work with digital pathology solution providers early in the design stage of process development to ensure the most efficient motion control solution possible,” Hennessey concludes.

ALIO Industries welcomes the opportunity to discuss motion control requirements with digital pathology customers, and to demonstrate how its solutions can contribute to cutting-edge and innovative products for this growing area of industry.